Wiredrawing line for wiredrawing a metal wire, wire rod or strap

A metal wire and wire technology, applied in the field of wire drawing, can solve problems such as power loss, electromagnetic problems, and long power cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

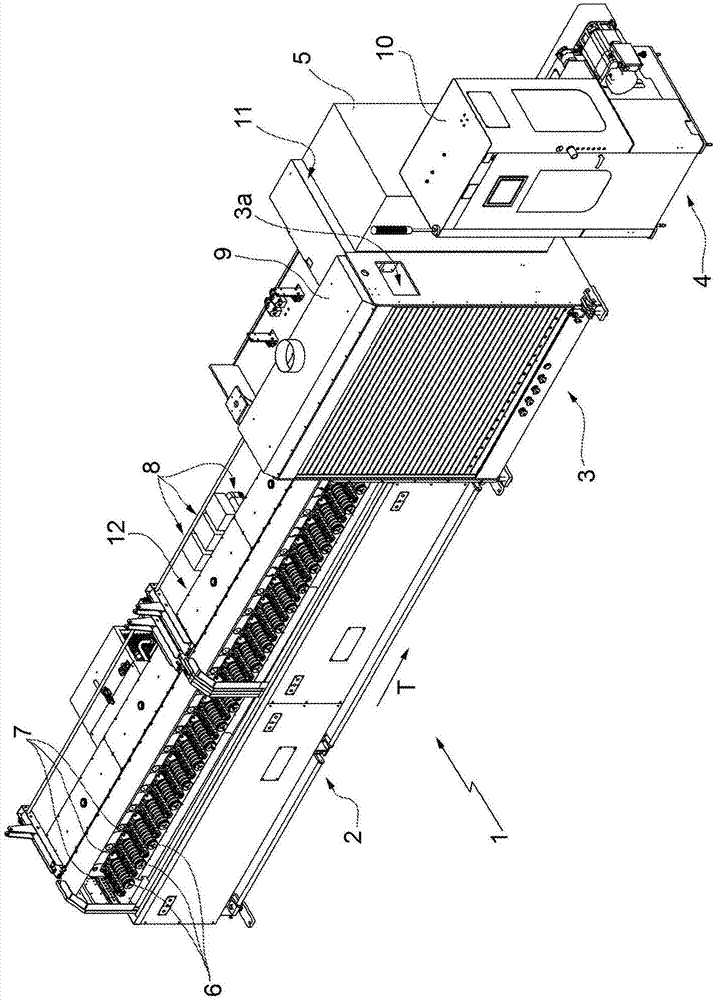

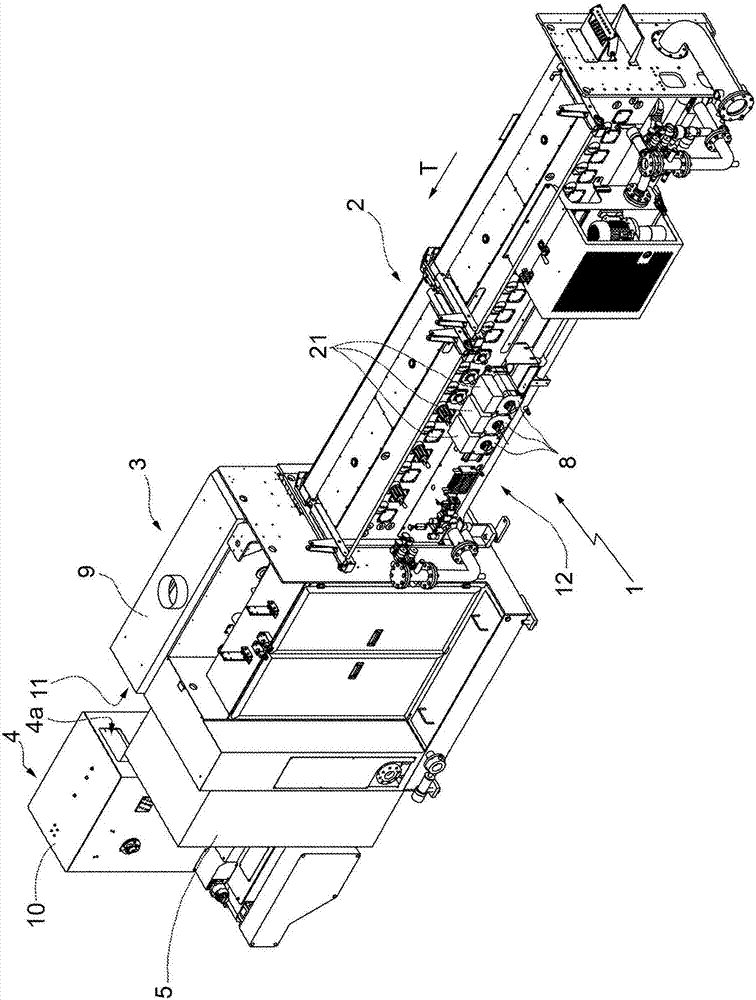

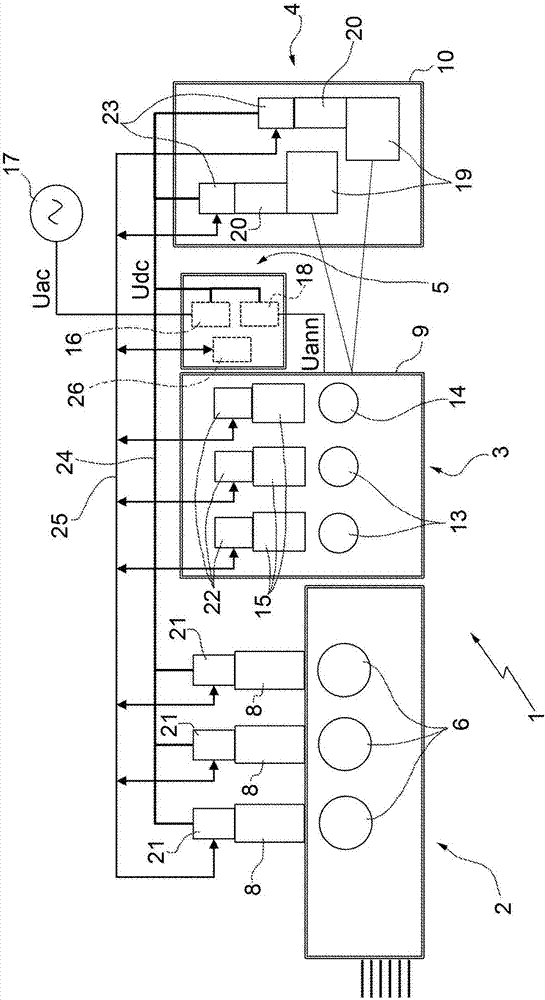

[0014] exist figure 1 with figure 2 In , reference numeral 1 generally designates the multifilament drawing wire according to the invention as a whole. The wire drawing line 1 includes a multi-wire drawing machine 2 arranged in the following order according to the drawing direction T, an annealing furnace 3, and a winding machine 4. The multi-wire drawing machine 2 receives a plurality of metal wires and performs their drawing to reduce their cross-sections, anneal The furnace 3 receives the hard-drawn wire from the wire drawing machine 2 and performs a DC resistance annealing of the wire, and the winder 4 is designed to wind the annealed wire on corresponding spools. The annealing furnace 3 comprises a control board 5 housing known electrical means for generating a so-called annealing voltage. The drawing wire 1 is shown not in use, i.e. there is shown no raw wire at the input of the wire drawing machine 2 and at the output 3a of the annealing furnace 3 ( figure 1 ) (that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com