Container handling plant including handling stations and sideways transfer of containers

A technology for processing equipment and processing stations, which is used in transportation and packaging, non-mechanical conveyors, conveyor objects, etc., and can solve the problems of expensive and bulky equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In the following description, parts having the same structure or similar function are denoted by the same reference numerals.

[0039] In the following description, a single orientation mark attached to each shuttle 18 is used without limitation. According to the moving direction of the shuttle 18, the azimuth indicator has a longitudinal direction from back to front, a vertical direction from bottom to top and orthogonal to the moving plane of the shuttle 18, and a transverse direction from the inside to the outside of the line.

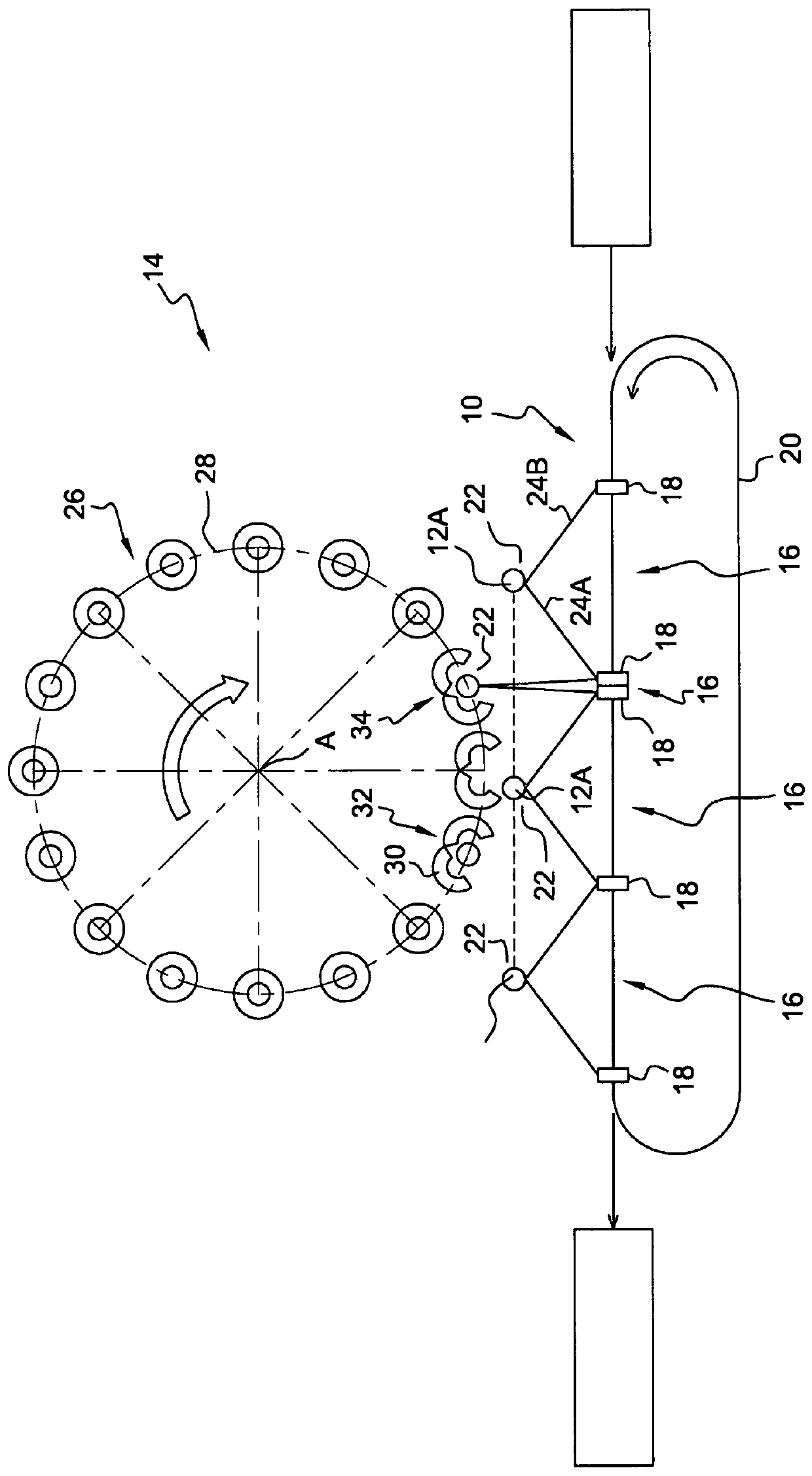

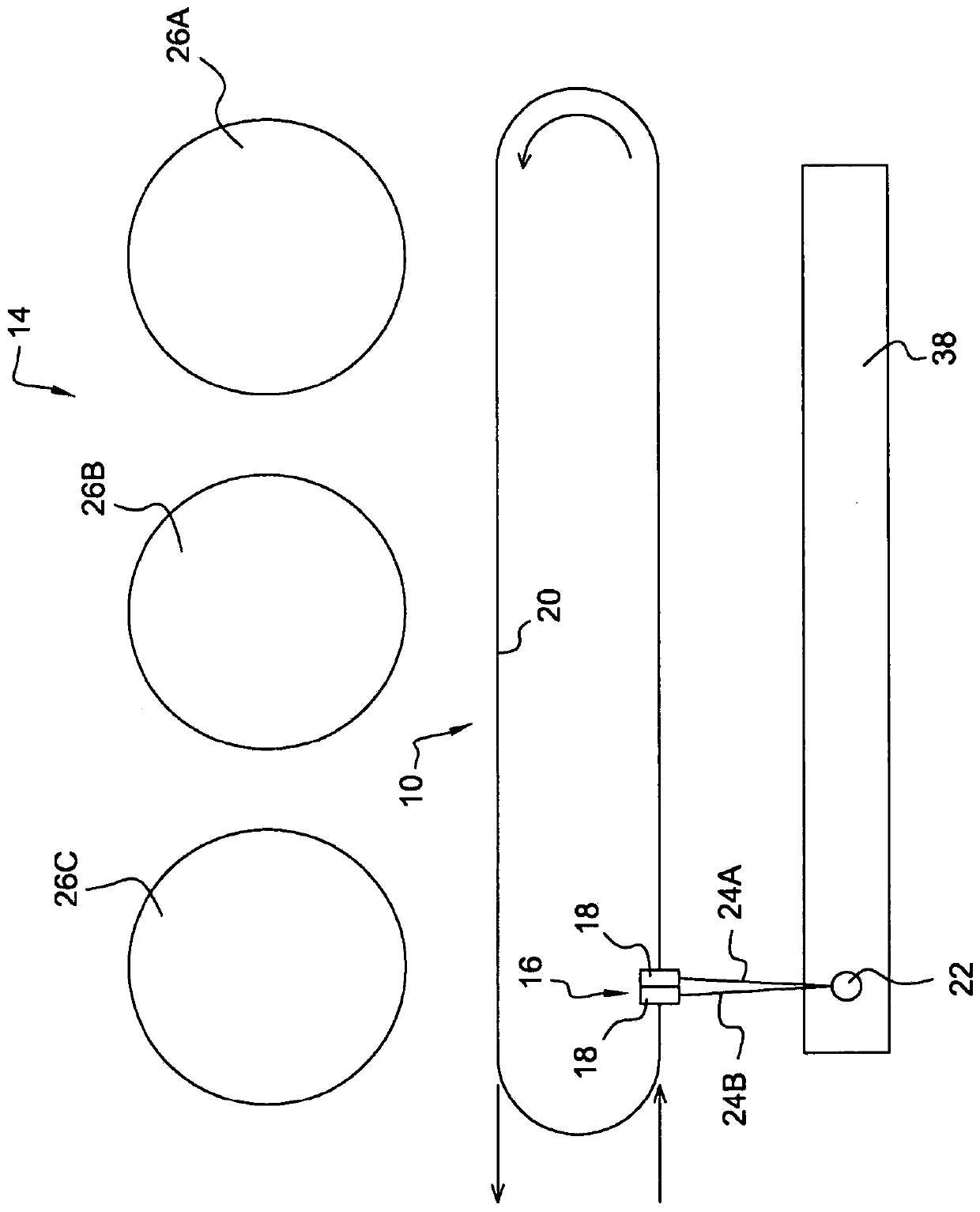

[0040] figure 1 The container conveying device 10 is particularly a container 12A made of a thermoplastic material such as polyethylene terephthalate (PET). The transfer device 10 is intended to be arranged in a container processing plant 14 that processes final containers, such as bottles, starting from the preform.

[0041] The transport device 10 of the container 12A is here adapted to transport the initial container (preform) or the intermediat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com