A pressurised liquid delivery system

A pressurized liquid and liquid technology, applied in the direction of liquid distribution, liquid injection device, liquid flow control device, etc., can solve the problems of not being able to obtain preparation opportunities, functional only mechanical movement, and not being able to get wet safely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

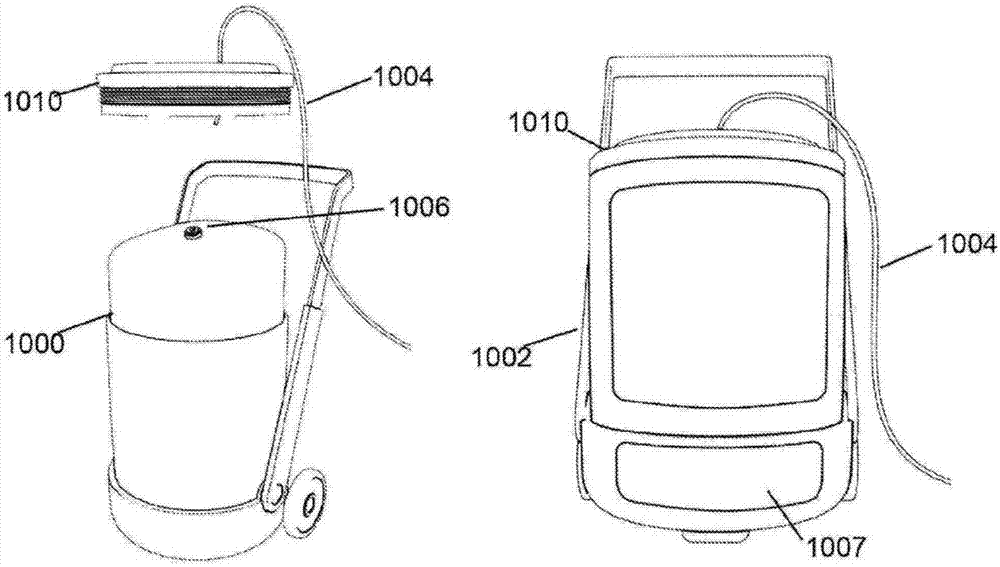

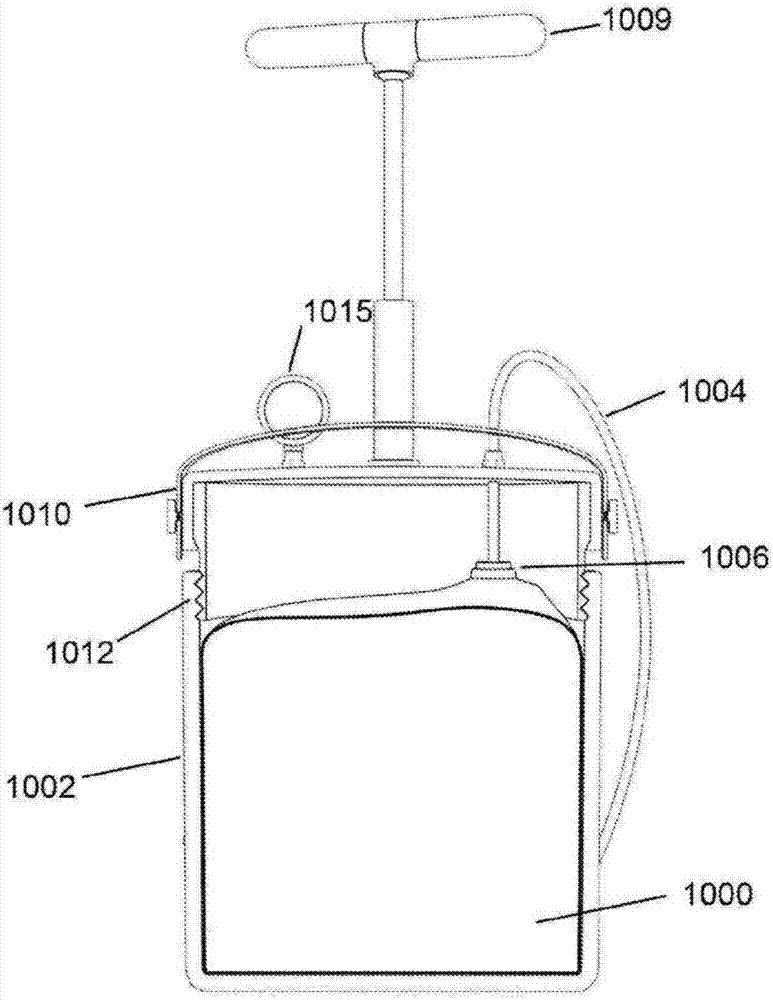

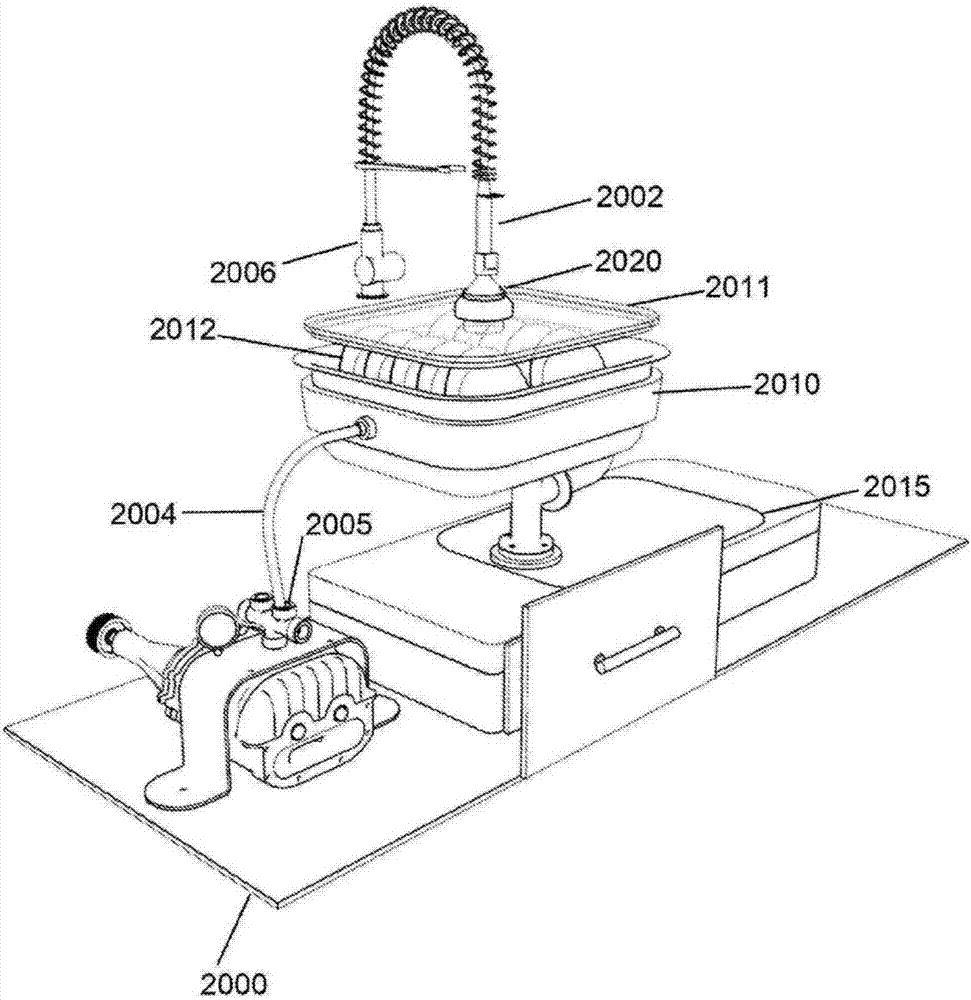

[0066] exist figure 1 and 2 contains liquids (eg, figure 1 in paint, figure 2 milk, fuel, etc.) in a bladder 1000 contained in a sealed structure 1002 (for example: figure 1 paint cans in figure 2 milk fridge, fuel tank, etc.) and pressurized with air supplied by an electric compressor 1007, supplied by a manual pressure pump 1009 or some other similar device entering through a pipe, inlet valve. The bladder 1000 is connected to the outlet valve 1006 and hose 1004 with no (or minimal) mechanical parts and the contained liquid is siphoned out due to the pressure equalization effect. The delivery of liquid is controlled by a tap or other trigger (not shown) at the outlet valve 1006 and / or the end of the hose 1004 . The structure 1002 may have a cover 1010 threadably fastenable 1012 to the structure 1002 . A pressure gauge 1015 can also be used.

[0067] Currently, household faucets (eg: kitchen, laundry, bathroom, etc.) are limited in their effectiveness by the level of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com