Continuously-arranging-type cereal clearing and processing device

A processing device and row-type technology, applied in grain processing, grain pod removal, grain shelling, etc., can solve problems such as unfavorable gluten aggregation, low efficiency of grain peeling, slow continuous grain processing speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

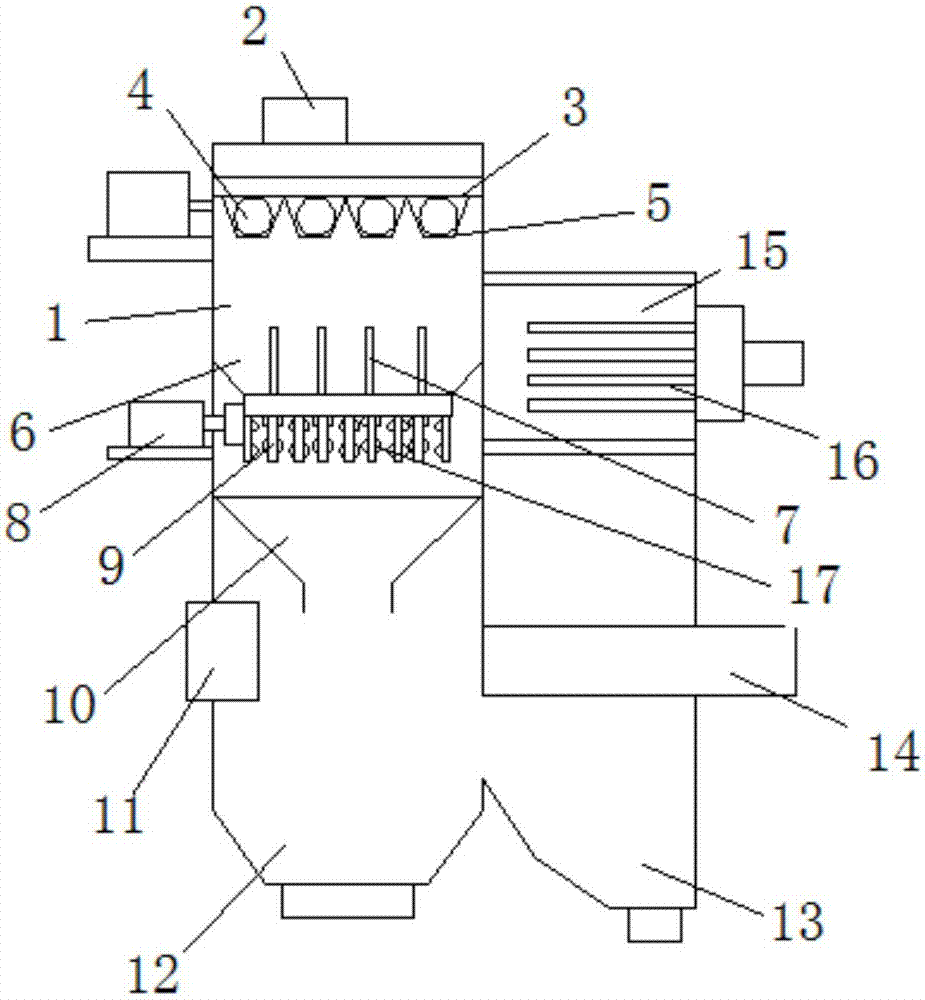

[0011] Referring to the accompanying drawings, a row-type grain cleaning and processing device includes a cabinet 1, the top of the cabinet 1 is provided with a feed port 2, and a plurality of row-type recesses are arranged in the cabinet below the feed port 2. Groove 3, the peeling roller 4 is installed in the rotation of the groove 3, the bottom of the groove 3 is provided with a discharge port 5, the bottom of the discharge port 5 is provided with a conical discharge hopper 6, the bottom The surface of the hopper 6 is provided with a plurality of partitions 7, and the lower surface of the lower hopper 6 is provided with a rubbing plate 17, and the rubbing plate 17 is driven by the rotation of the motor 8 and forms friction with the side plate 9. The below of the hopper 6 is provided with a hopper 10, and one side of the hopper 10 is provided with a blower 11, and the below of the blower 11 is provided with a grain outlet 12 and a husk outlet 13, and the side of the blower 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com