Double-head type mold cutting device

A die cutting and die technology, which is applied in the field of double-head die cutting devices, can solve the problems of shortening the service life of the equipment, cumbersome and other problems, and achieve the effect of saving time and cost, improving work efficiency and realizing automatic integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

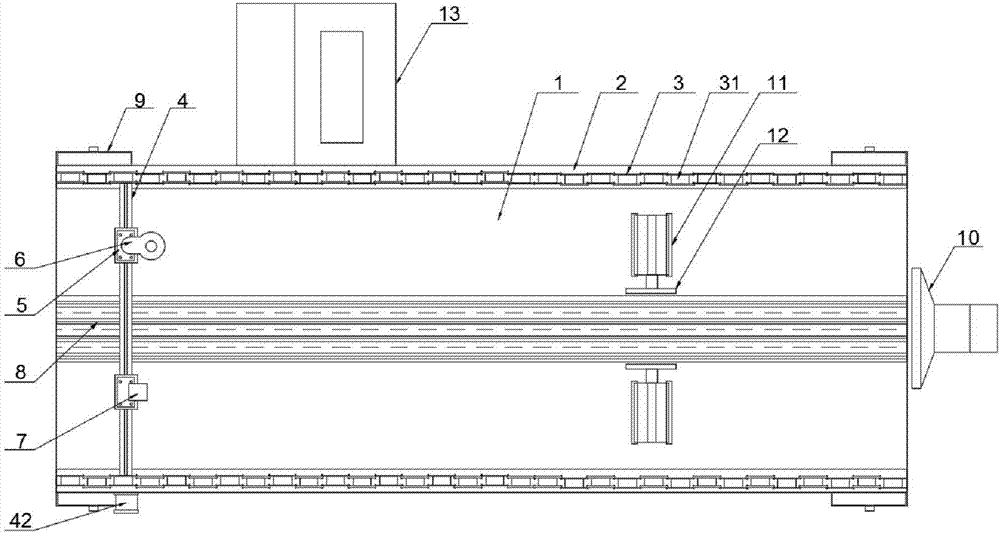

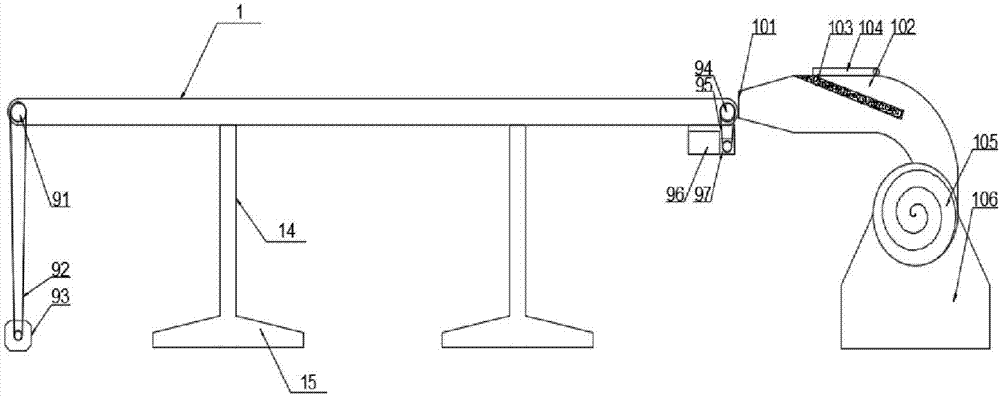

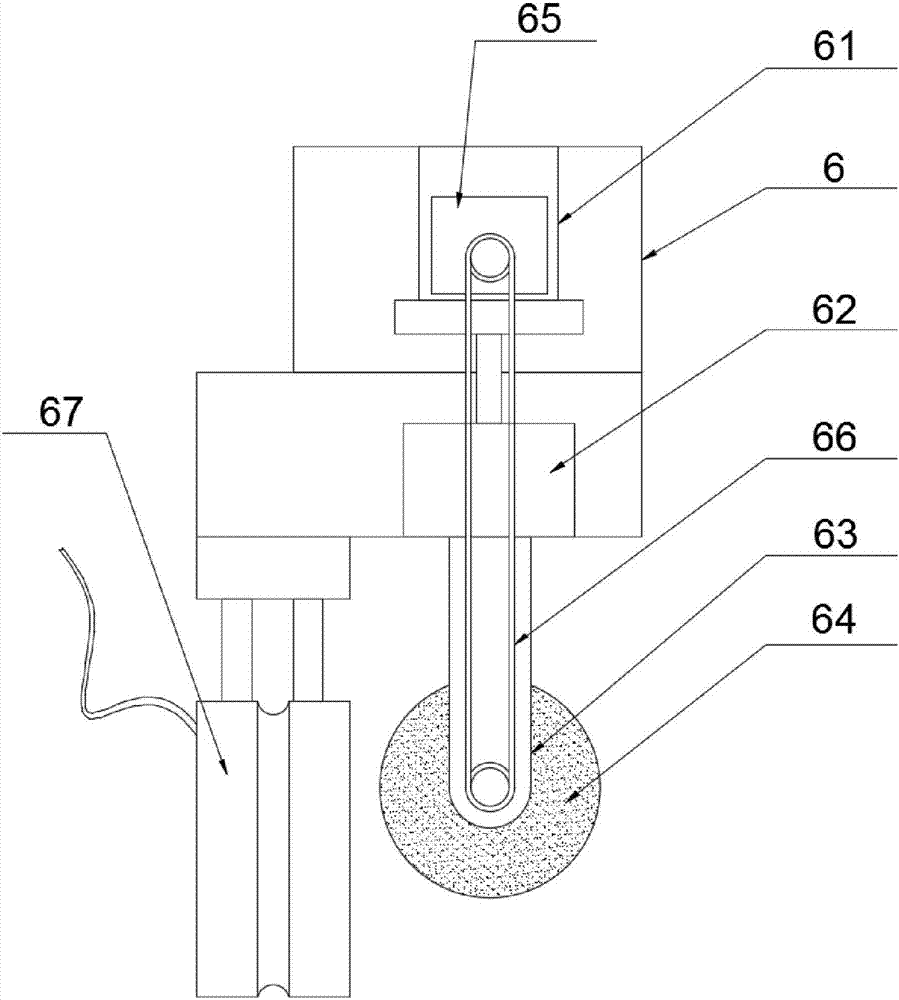

[0027] A double-head mold cutting device, including a worktable 1 and chain grooves 2 on both sides of the worktable 1, chain grooves 2 are installed with chains 3 in a ring shape, and a straight line is fixed horizontally between the chains 3 on both sides Guide rail 4, two sliders 5 of the same specification are fixed on the linear guide rail 4, a cutting mechanism 6 is installed on one slider 5, and a marking mechanism 7 is installed on the other slider 5. The surface of the linear guide rail 4 is set Leading screw 41 is arranged and leading screw 41 is threadedly connected with slide block 5, and the inside of cutting mechanism 6 is provided with decelerating motor 61, and the output shaft of decelerating motor 61 is fixedly connected with the rotating block 62 of its bottom, and the bottom of rotating block 62 is provided with two Block cutting arm 63, and saw blade 64 is connected with rotating shaft rotation between two cutting arms 63, the inside of cutting mechanism 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com