Method for removing burrs on surface of stainless steel strip

A stainless steel strip and burr technology, which is applied to the parts of grinding machine tools, machine tools suitable for grinding the edge of workpieces, grinding machines, etc., can solve the problems of affecting processing, low efficiency, and increased production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

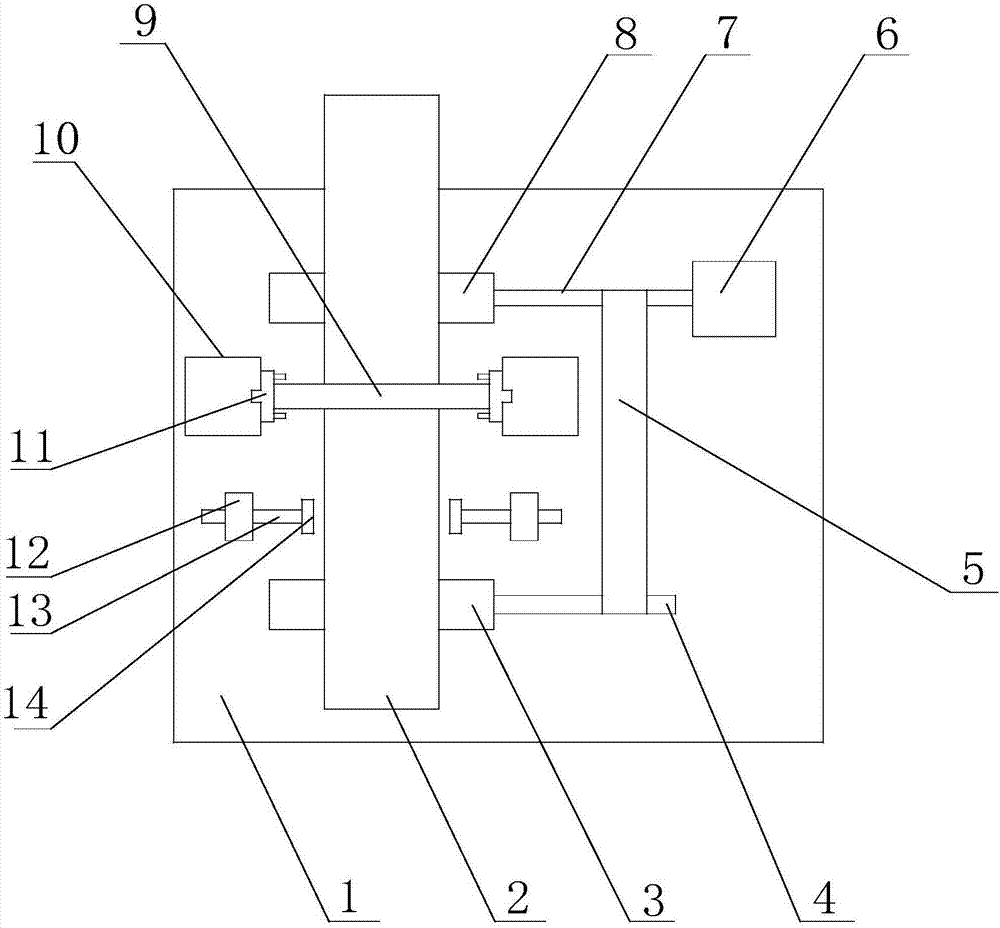

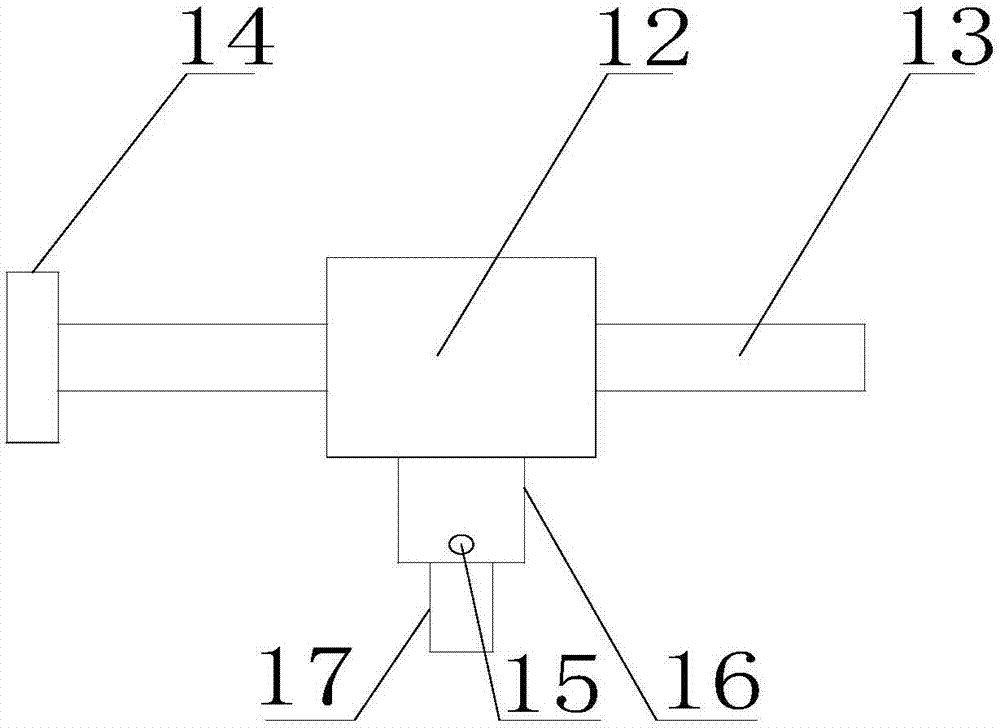

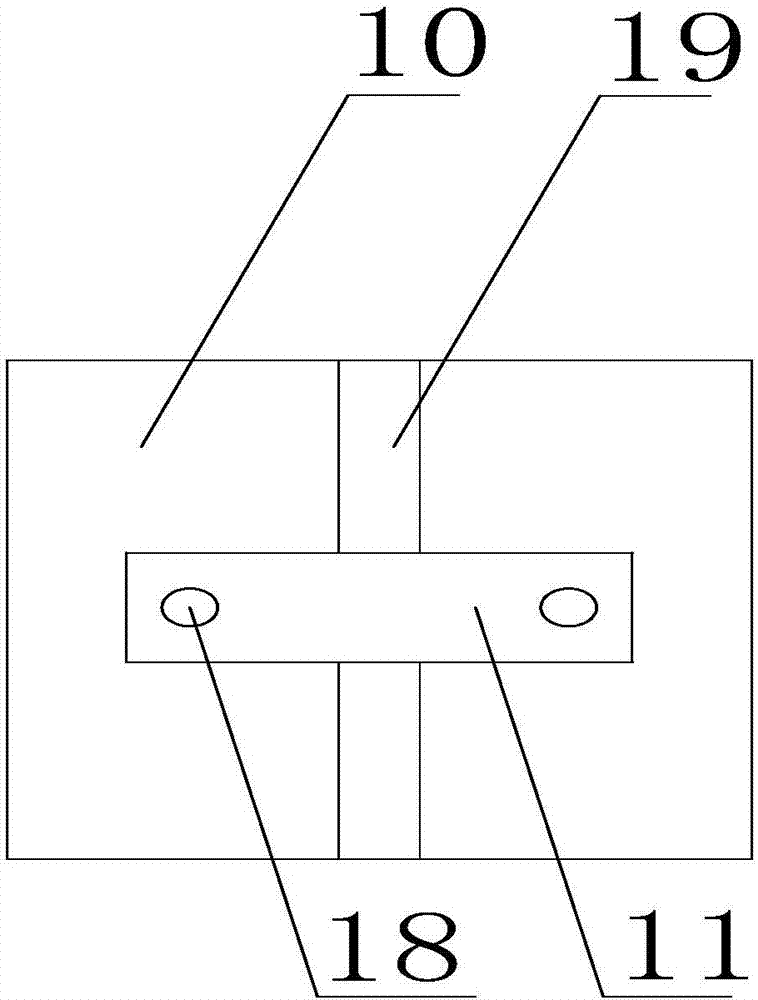

[0025] Such as Figure 1 to Figure 4 As shown, the method for removing burrs on the surface of stainless steel strips of the present invention includes the following steps: firstly, the steel strip 2 that needs to be deburred is placed on the first roller 3 and the second roller 8, and the slider 11 is slid, so that the cross bar 9 The polishing layer 20 of the steel belt 2 is attached together with the upper surface of the steel belt 2, and the positioning rod 18 is rotated so that the positioning rod 18 fixes the slider 11 on the fixed table 10, and then the movable rod 13 is rotated so that the grinding head on the movable rod 13 14 is attached to the side surface of the steel belt 2, and the motor 6 is turned on. The output end of the motor 6 drives the second transmission rod 7 to rotate, and the second transmission rod 7 drives the second roller 8 to rotate together. At the same time, the second transmission rod 7 The belt 5 drives the first transmission rod 4 to rotate,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com