Quick die replacing device for prefabricated member flat die

A technology of prefabricated components and flat molds, which is applied in the field of quick mold change devices for flat molds of prefabricated components, which can solve the problems of cumbersome fixing and demoulding process of side molds, troublesome process of cleaning table tops, discount of fixing effect of side molds, etc., and achieve saving The effect of using materials, improving production efficiency, and saving mold change time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

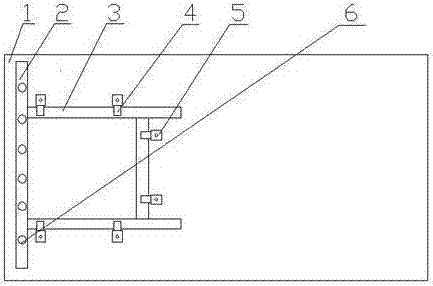

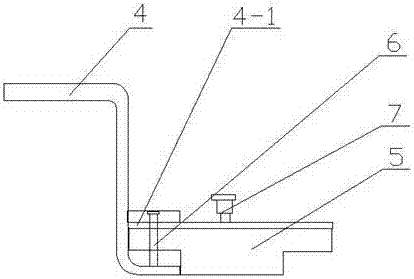

[0028] as attached figure 1 , attached figure 2 Shown: a quick mold change device for flat molds of prefabricated components, including a reference rib 2 and three positioning ribs 3 located on a magnetic trolley 1, the reference rib 2 and three positioning ribs 3 form a closed Plane, according to the length, width and height of the required prefabricated components, select the appropriate length and height of the positioning rib 3 and the intercepted reference rib 2 of appropriate length to form a closed plane. The height and length of the reference rib 2 are generally reserved , which is convenient for the universality of the reference rib 2, and the prefabricated components that meet the requirements can be obtained by pouring concrete in this airtight plane; in the actual operation process, an additional layer can be added between the positioning rib 3 and the trolley 1 The water retaining strip is used to increase the sealing between the positioning rib 3 and the trolle...

Embodiment 2

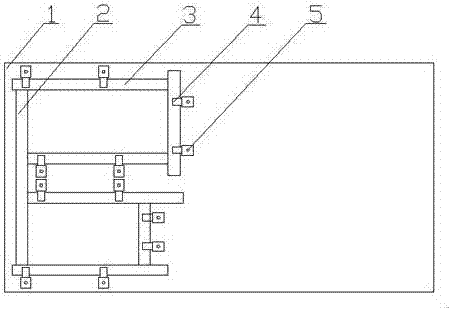

[0035] as attached image 3 , attached Figure 4 Shown: a quick mold change device for flat molds of prefabricated components, including a reference rib 2 and six positioning ribs 3 on the magnetic trolley 1, the reference rib 2 and the positioning ribs 3 can form two airtight Plane, two planes share a reference rib 2, intercept the length of the required reference rib 2 according to the needs, and pour concrete into the two enclosed planes at the same time, and two same or different prefabricated components can be carried out at the same time Preparation, the reference rib 2 is installed on the edge of the upper surface of the trolley 1 by welding to ensure that the position stability of the reference rib 2 on the trolley 1 is high, and the outer surface of the reference rib 2 is provided with a scale ( Not shown in the figure), it is convenient to quickly intercept a certain length of the reference rib 2, and it is also convenient to quickly find the connection point betwee...

Embodiment 3

[0040] as attached image 3 , attached Figure 5 Shown: the difference between the pressing plate in this embodiment and embodiment 2 is that: the number of pressing mechanisms 8 on the first support part of each pressing plate 4 is two, and the locks of the pressure rods 9 in the two pressing mechanisms 8 The tightening direction is opposite, so that when receiving a force in one direction, at least one pressure bar 9 is not affected by external force, which is beneficial to improve the stability of the formwork. This approach can effectively save the consumption of the magnetic box 5 while increasing the number of pressing points to ensure the stability of the positioning rib 3, which is beneficial to saving production costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com