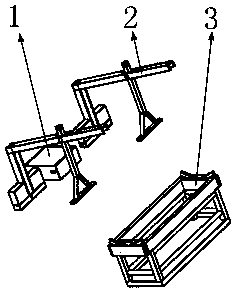

An anti-tilt hanging platform used in a high-rise building

An anti-tilt, high-rise technology, applied in the direction of construction, building structure, scaffolding supported by house structure, etc., can solve the problems of reduced service life of ropes and overall service life of the platform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

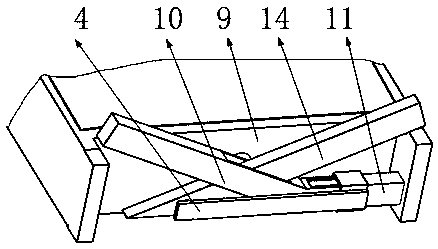

[0071] The specific embodiment: when working on the table; the drive motor 33 drives the motor 33 rotating shaft 13 to rotate; the motor rotating shaft 13 can drive the fourth gear 32 to rotate; the fourth gear 32 drives the third gear 31 to rotate; the third gear 31 drives the first gear shaft 37 rotates; the first gear shaft 37 drives the gear mechanism 28 that is installed on it to rotate; simultaneously the first gear shaft 37 rotates and drives the second gear 30 to rotate; the second gear 30 rotates to drive the first gear 29 to rotate; the first gear 29 rotates Drive the second gear shaft 38 to rotate; the rotation of the second gear shaft 38 drives the gear mechanism 28 installed on it to rotate; the rotation of the gear mechanism 28 makes the steel rope wound on it move; the steel rope moves through the corresponding transition wheel 20 in turn , and finally drive the two first drive plates 10 and the two second drive plates 14 to drive the entire suspension mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com