Method for identifying insulation fault of gas insulation combined electrical appliance based on photoacoustic spectral information

A gas-insulated combination and insulation fault technology, which is applied in the direction of using optical methods for testing, instrumentation, and electrical measurement, can solve problems such as difficult fault diagnosis and maintenance, and long time-consuming offline maintenance, so as to achieve rigorous and reliable fault diagnosis process and ensure accuracy performance, ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in combination with specific embodiments.

[0023] One, at first introduce the method principle of the present invention.

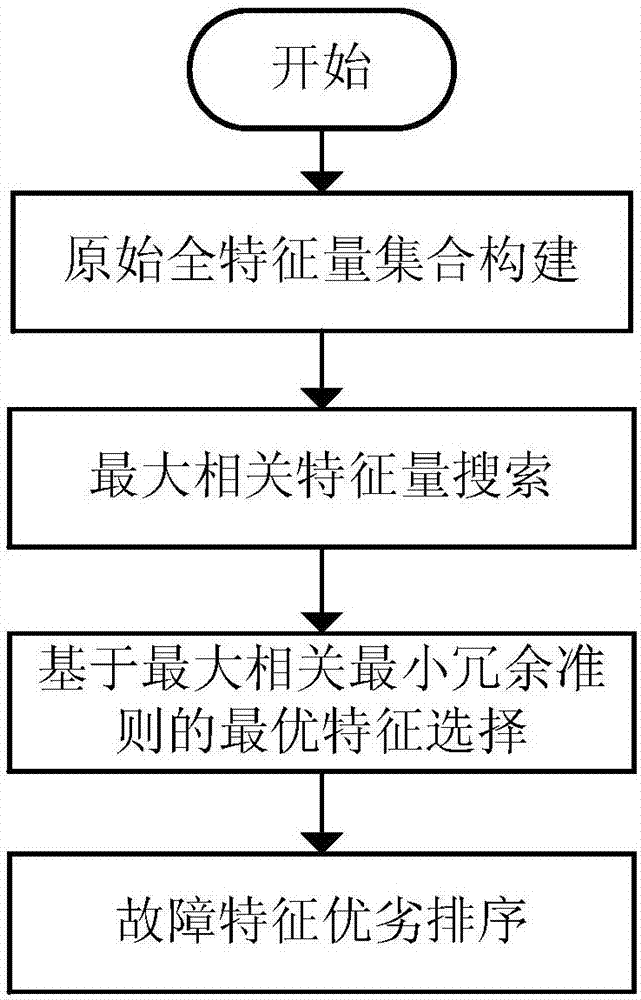

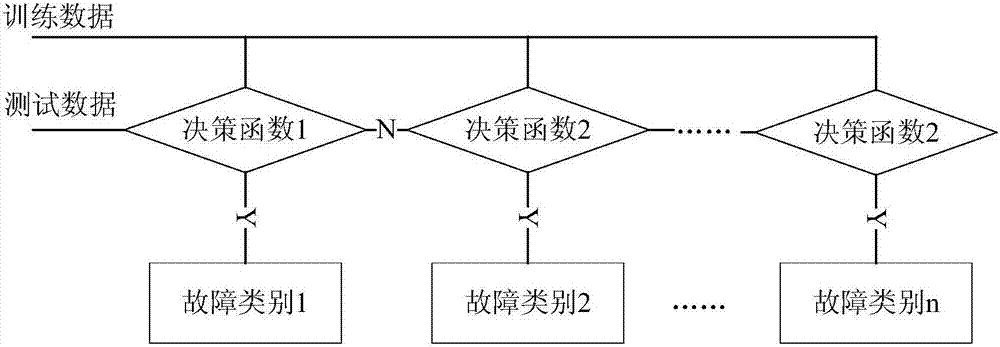

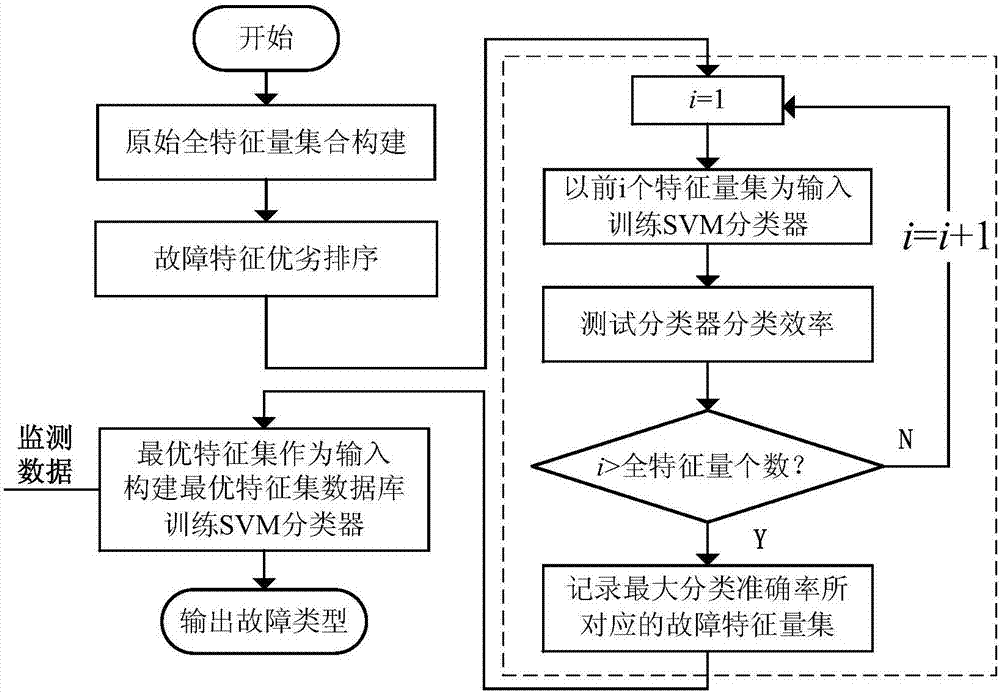

[0024] Before using this method, the preliminary data preparation of the GIS gas component photoacoustic spectroscopy online monitoring system is required. Using a large amount of photoacoustic spectrum fault information data accumulated in advance, the original training database is constructed to complete the optimization of fault feature quantities and the training of support vector machine classifiers, such as image 3 shown. The photoacoustic spectrum detection component information database supported by the present invention comes from a large amount of experimental data carried out in advance.

[0025] The SF that the present invention can obtain6 The monitoring components of equipment fault characteristics are CO, CF 4 , CO 2 (Gas unit: μL / L), referring to the fault feature constructi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com