Multi-gear window lifting switch

A multi-gear and switch technology, applied in the direction of electric switches, flip/rocker switches, flip switches/rocker switches, etc., can solve the problems of unsatisfactory users, soft key operation force cannot reach high, and life limitations sexual issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

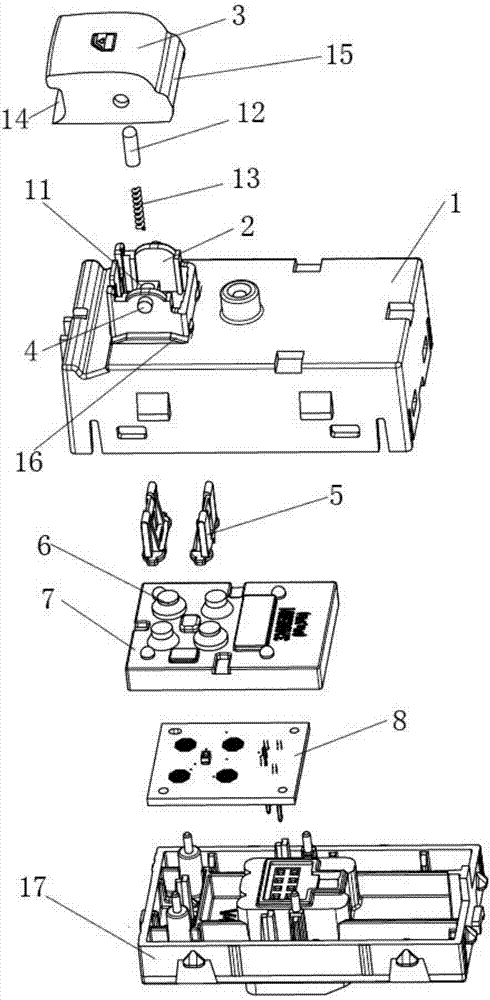

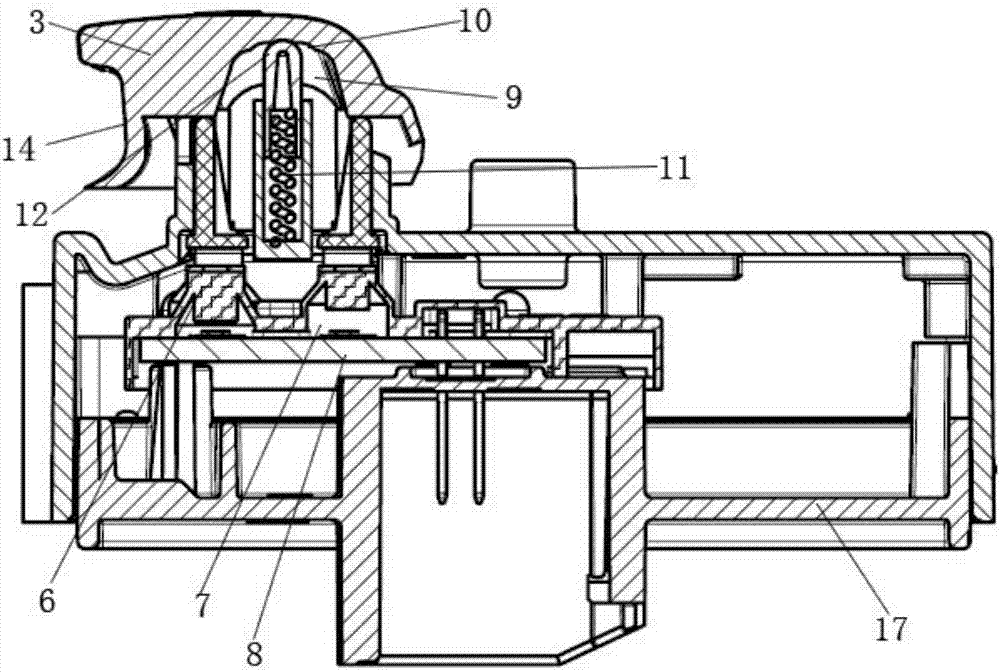

[0018] Specific embodiment: two transmission parts 5 are preset in the housing 1, and a soft button boss 6 is arranged directly below each transmission part 5;

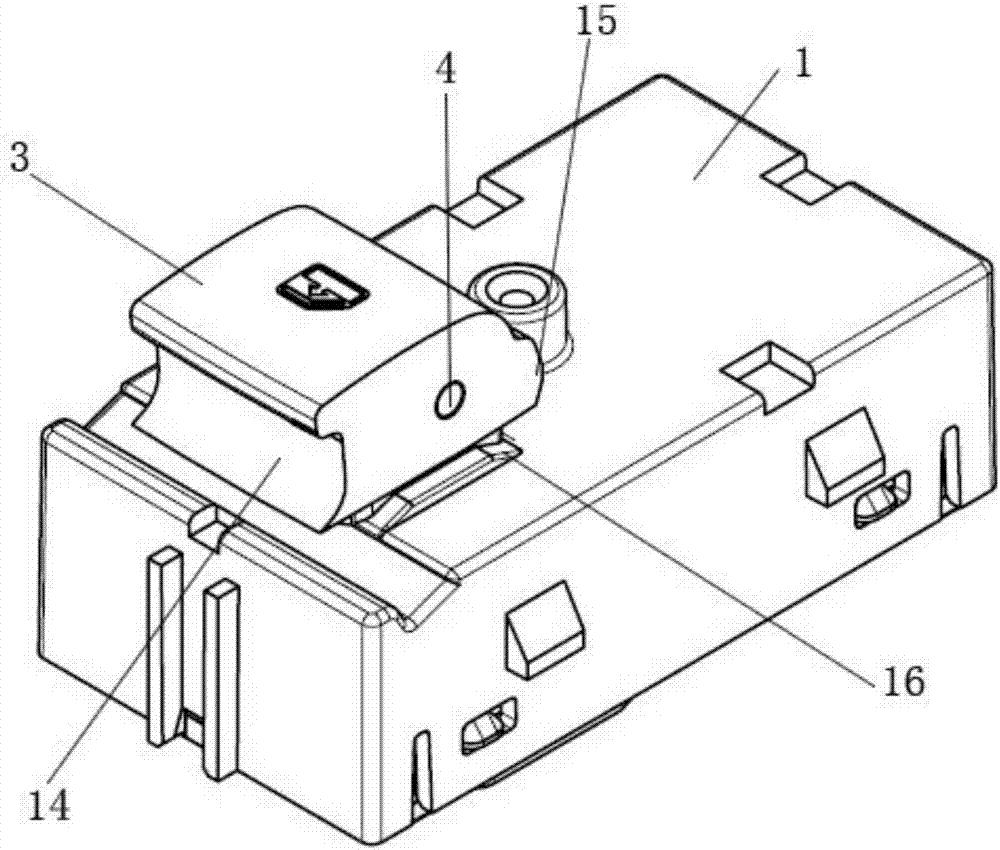

[0019] The front end of the button 3 is provided with an inner concave end surface 14, and the inner concave end surface 14 is used for convenient force application by fingers;

[0020] The lower part of the rear end surface of the button 3 is a circular arc transition 15 , and the housing 1 is provided with a guide slope 16 corresponding to the position of the circular arc transition 15 to ensure the smooth rotation of the button 3 .

[0021] After adopting the structure of the present invention, when a force is applied to the button so that the button 3 rotates around the revolving pin 4, the lower end pressing surface of the button 3 presses the upper end surface of the left transmission part in advance, and the lower end surface of the corresponding transmission part presses the soft button. The button boss until ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com