A double-stator hybrid excitation motor with T-shaped core inner stator

A hybrid excitation motor, inner stator technology, applied in the direction of electromechanical devices, electrical components, magnetic circuit static parts, etc., can solve the problems of space contradiction, heat dissipation difficulty, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

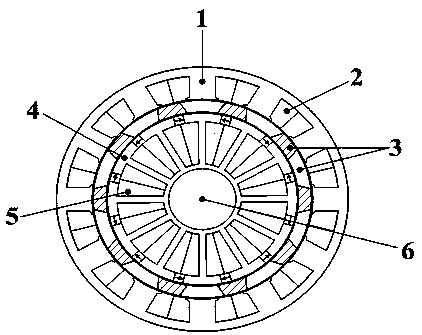

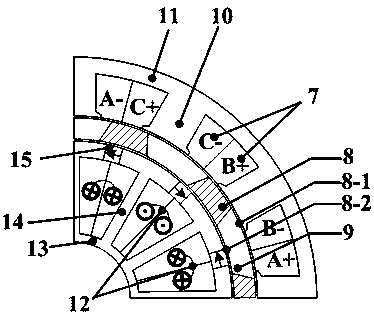

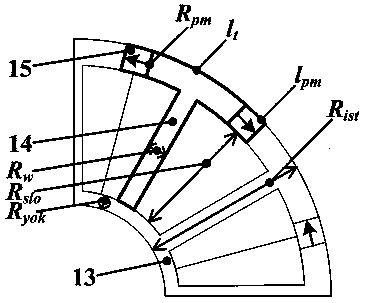

[0023] see figure 1 with figure 2 , the present invention includes an outer stator 1 , an intermediate rotor 3 , an inner stator 4 and a rotating shaft 6 . The intermediate rotor 3 is installed coaxially between the outer stator 1 and the inner stator 4 and rotates synchronously with the rotating shaft 6 . An outer air gap 8-1 is provided between the inner wall of the outer stator 1 and the outer wall of the intermediate rotor 3, and an inner air gap 8-2 is provided between the inner wall of the intermediate rotor 3 and the outer wall of the inner stator 4. The thickness of the air gap is related to the power level of the motor, The selected permanent magnet material is related to the processing and assembly process of the inner stator 4, the outer stator 1, and the intermediate rotor 3.

[0024] The outer stator 1 is composed of an outer stator yoke 11, 12 outer stator teeth 10 and 12 outer stator slots 2. The outer stator yoke 11 is evenly arranged with 12 outer stator te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com