Injection-molding-machine raw material filtering and screening pulverizer

A raw material crushing and injection molding machine technology, applied in the direction of coating, etc., can solve the problems of many impurities in the finished product, high scrap rate, difficult to remove, etc., and achieve the effect of low filtration cost and high qualified rate of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

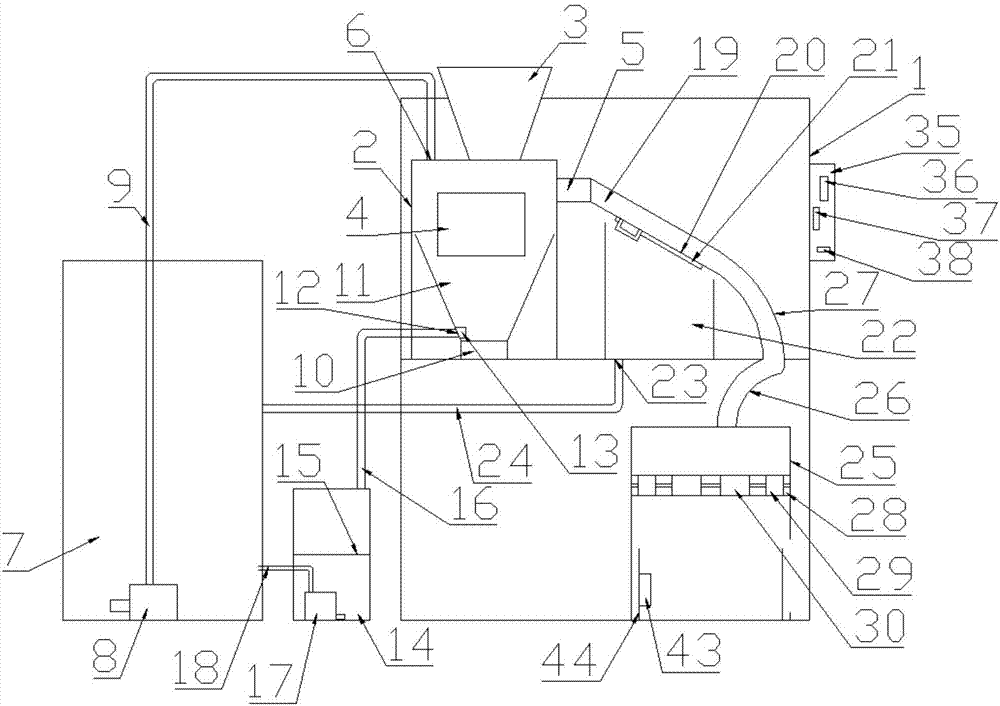

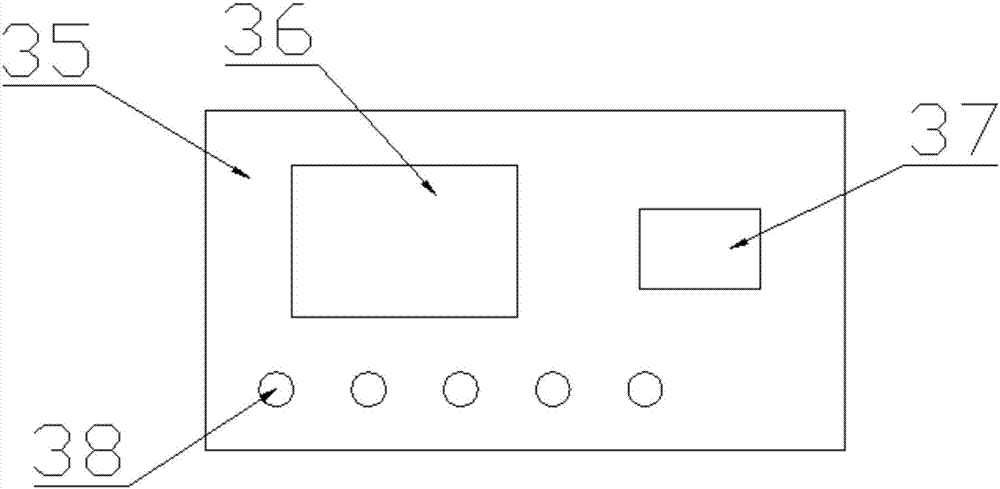

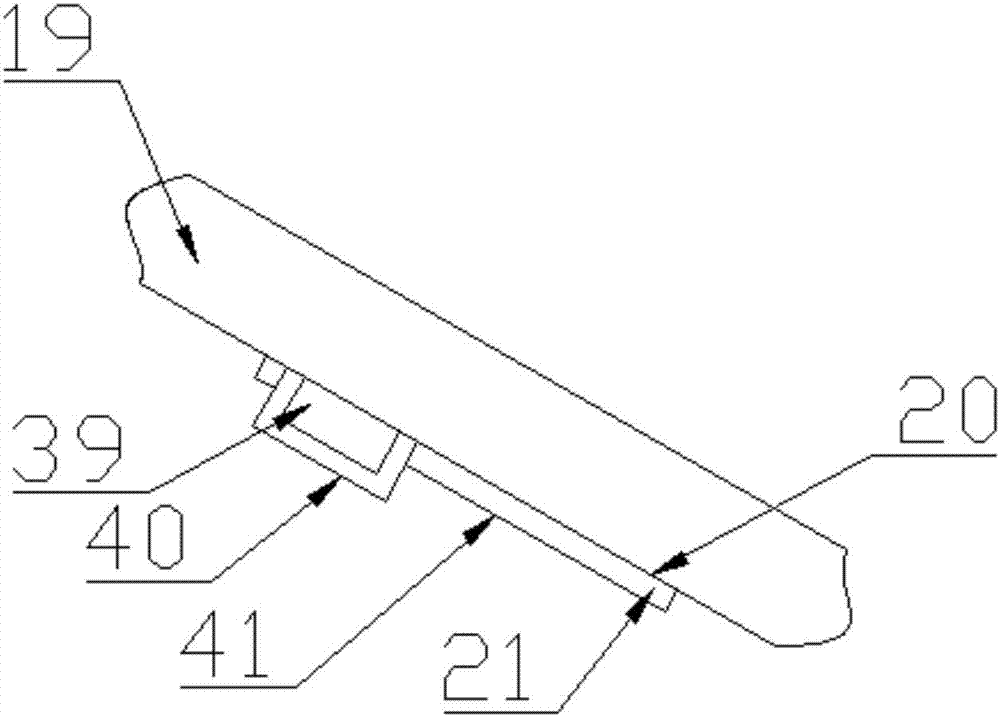

[0021] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5 As shown, a raw material filtering and screening pulverizer for an injection molding machine includes a frame 1, the frame 1 is fixedly installed on the ground, and a partition is arranged in the frame 1 to divide the frame 1 into two layers. A preliminary screening mechanism is provided in the frame 1, and the preliminary screening mechanism is composed of a screening box 2 fixedly installed on the partition, a tapered feed port 3 fixedly installed on the outer upper surface of the screening box 2, and the inside of the screening box 2. There is a certain amount of clear water 4, a square water outlet 5 located on one side of the screening box 2 and slightly below the horizontal plane, a water inlet 6 located on the upper surface of the screening box 2, a water tank 7 fixedly installed on the ground next to the side of the frame 1, located The water pump 8 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com