Filtering process for soy

A process method and technology of soy sauce, applied in the direction of filtration separation, separation method, chemical instrument and method, etc., can solve the problems of long filtration time, frequent blockage of filter rods, easy blockage of candle filter, etc., to reduce filtration time and reduce The effect of filtering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with drawings and embodiments.

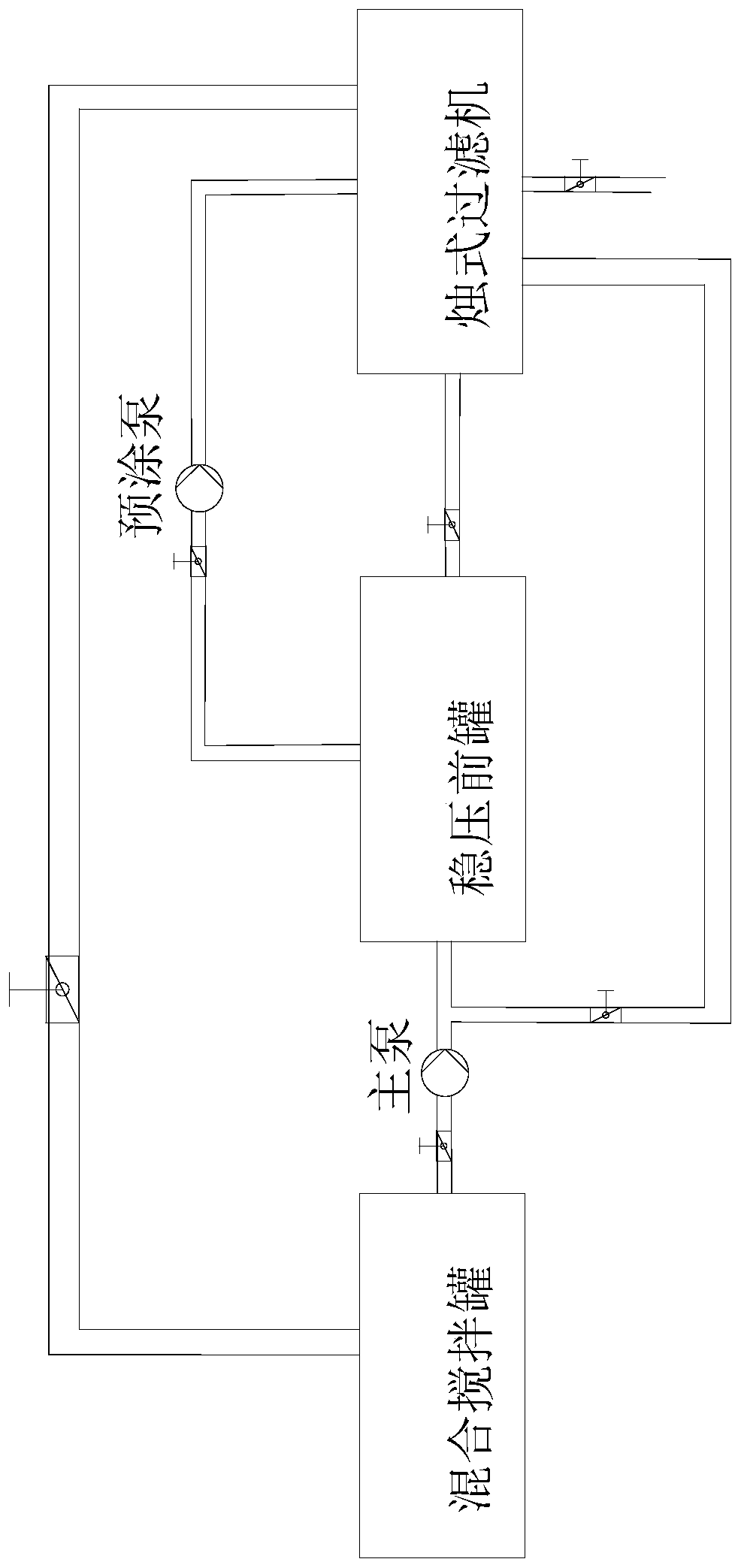

[0021] Such as figure 1 Shown, a kind of soy sauce filtering process, take filtering 80t soy sauce raw material as example, adopt candle type filter, comprise the following steps:

[0022] 1) Lower the soil: Pour 80t of soy sauce raw material and the first diatomite into a mixing tank and stir for a period of time, then let it settle and layer, and then obtain the supernatant and the sediment layer, wherein the weight of the first diatomite is The weight of the soy sauce stock solution is 1.5‰, the stirring time is 0.5 to 1 hour, the standing precipitation and layering time is 6 hours, the wet volume of the first diatomite is 3.0L / Kg, and the wet volume of the present invention is Diatomaceous earth absorbs the volume of pure water, and the first diatomaceous earth fully absorbs the impurities in the soy sauce raw material, reducing the phenomenon of clogging the filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com