Long rod warm forging forward extrusion mode-hopping-prevention die and method for machining product with same

A technology of long rods and dies, which is applied in metal processing equipment, manufacturing tools, forging/pressing/hammer devices, etc., can solve the problem that cold forging is difficult to achieve large deformation forging production, large return force, and large deformation. and other problems, to achieve the effect of simple mold structure design, preventing mold jumping phenomenon, and avoiding rapid ligament wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

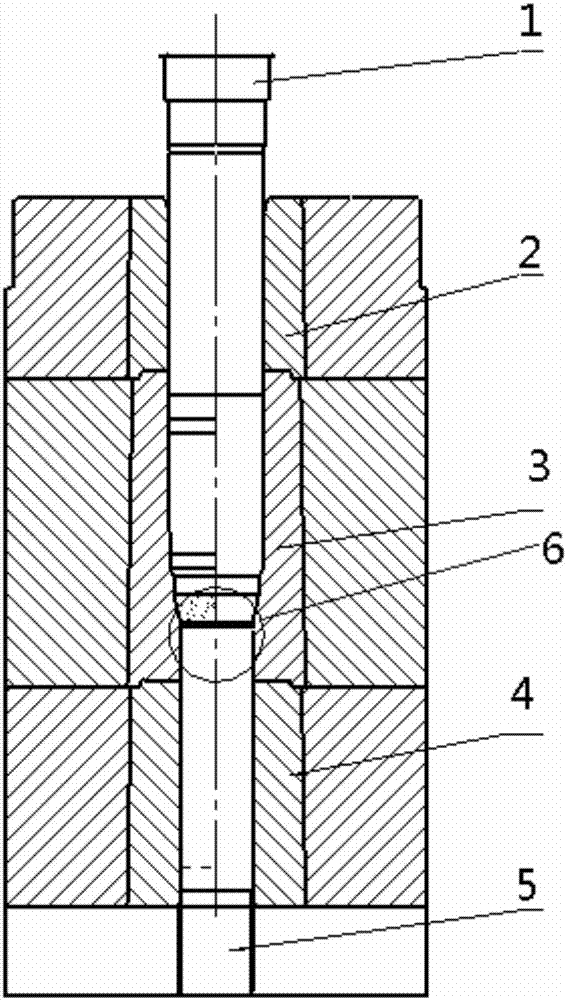

[0015] like figure 1 As shown, the present invention discloses a warm forging forward extrusion anti-jump mold for long rods, which includes a punch 1, a lower die a2, a lower die b3, a lower die c4, a stripper 5, a lower die a2, and a lower die b3 , The lower die c4 is discharged from top to bottom in sequence, the punch 1 is inside the lower die a2, the lower die b3, and the lower die c4, the ejector 5 is below the punch 1, and the tapered ligament 6 is designed on the lower die b3. The design of the tapered ligament 6 solves the problem of forming, and also solves the problem that the product always rubs against the ligament when the material is returned, avoids problems such as rapid wear of the ligament and mold hopping caused by large material ejection force, and prevents the phenomenon of mold hopping.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com