Novel forming method for internal lines of full-body marble tile blank

A technology of marble and green body, which is applied in the field of forming the internal lines of the new-style full-body marble tile body, which can solve the problems of loose lines, poor fineness, and uncontrollable line positions, etc., and achieve fine effects and clear boundaries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

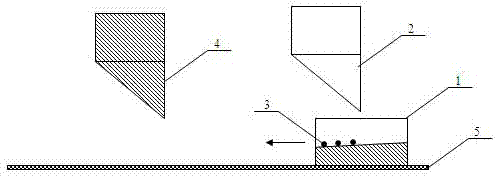

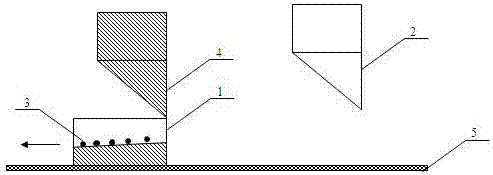

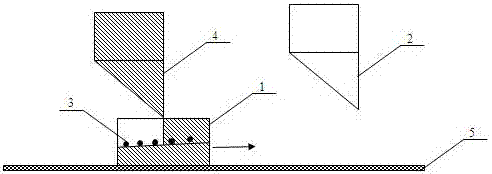

[0015] refer to Figure 1a to Figure 1d , a method for forming the internal lines of a novel whole-body marble tile body, including the following process: the grid 1 is returned from the press with material, and the powder of the body body in the grid 1 is due to friction and friction between the glass platform 5 The inertia factor will form a certain degree of powder slope. When the grid 1 passes under the line hopper 2, the lower gate of the line hopper 2 opens and closes instantly, and the line powder 3 freely falls into the main body of the green body in the grid 1 under the action of gravity. powder slope ( Figure 1a ), as the grid 1 moves, a line layer is formed on the powder slope of the body body in the grid 1, and then the grid 1 continues to return to the initial position and stops ( Figure 1b ), then it is controlled by the travel switch to mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com