Automatically-opening-closing material taking device

A reclaiming device, self-opening and closing technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of difficult mechanical grasping, poor replacement, slow reclaiming speed, etc., to protect transportation materials and improve line efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

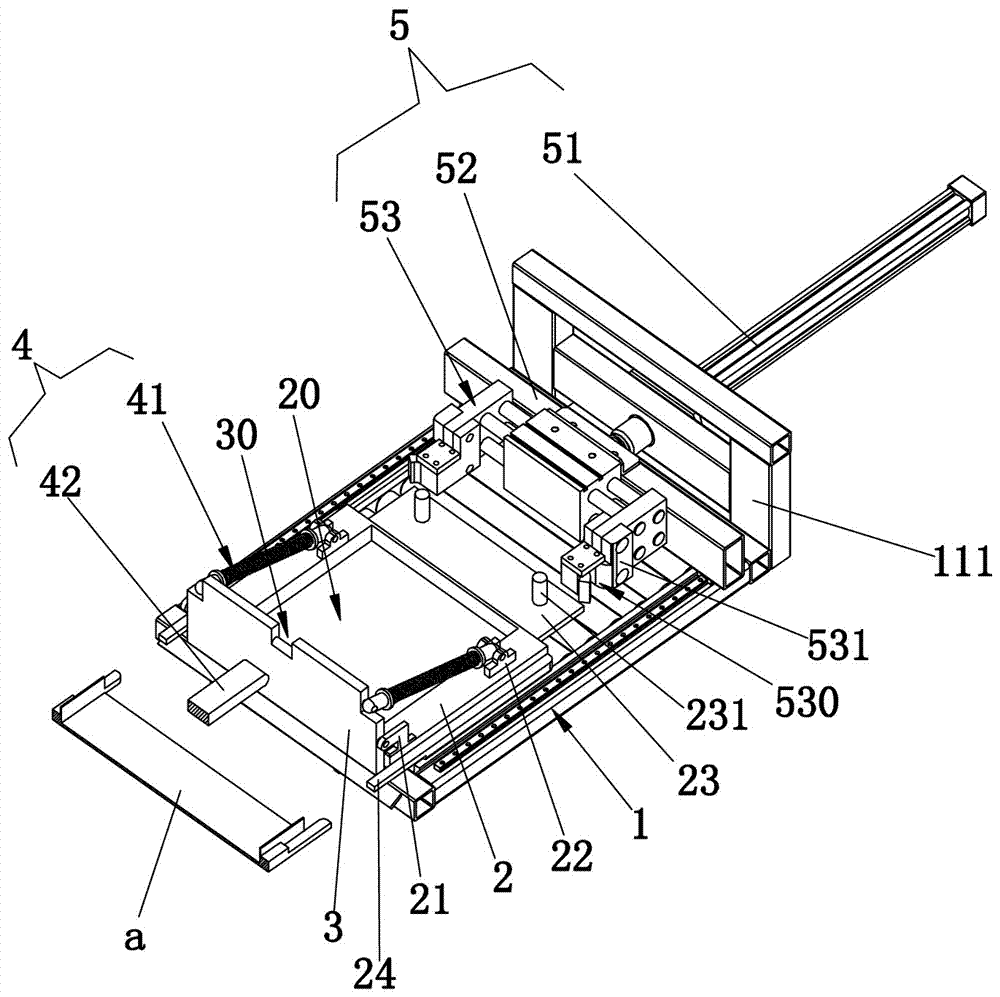

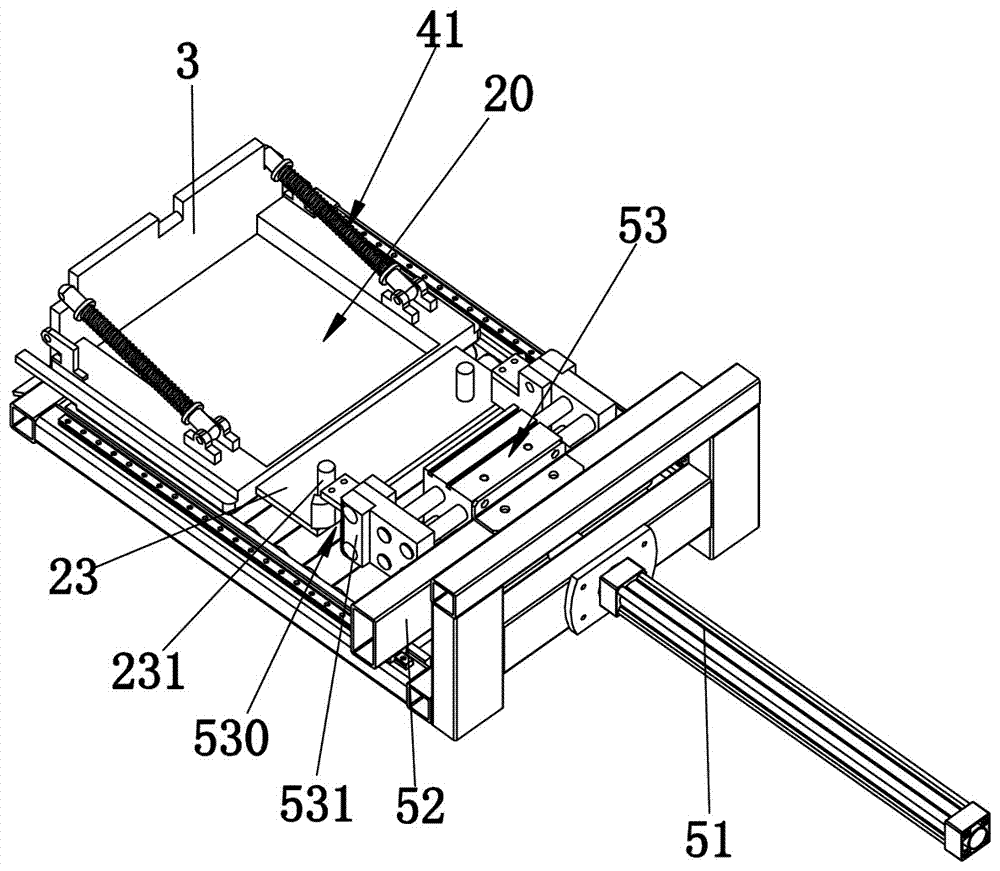

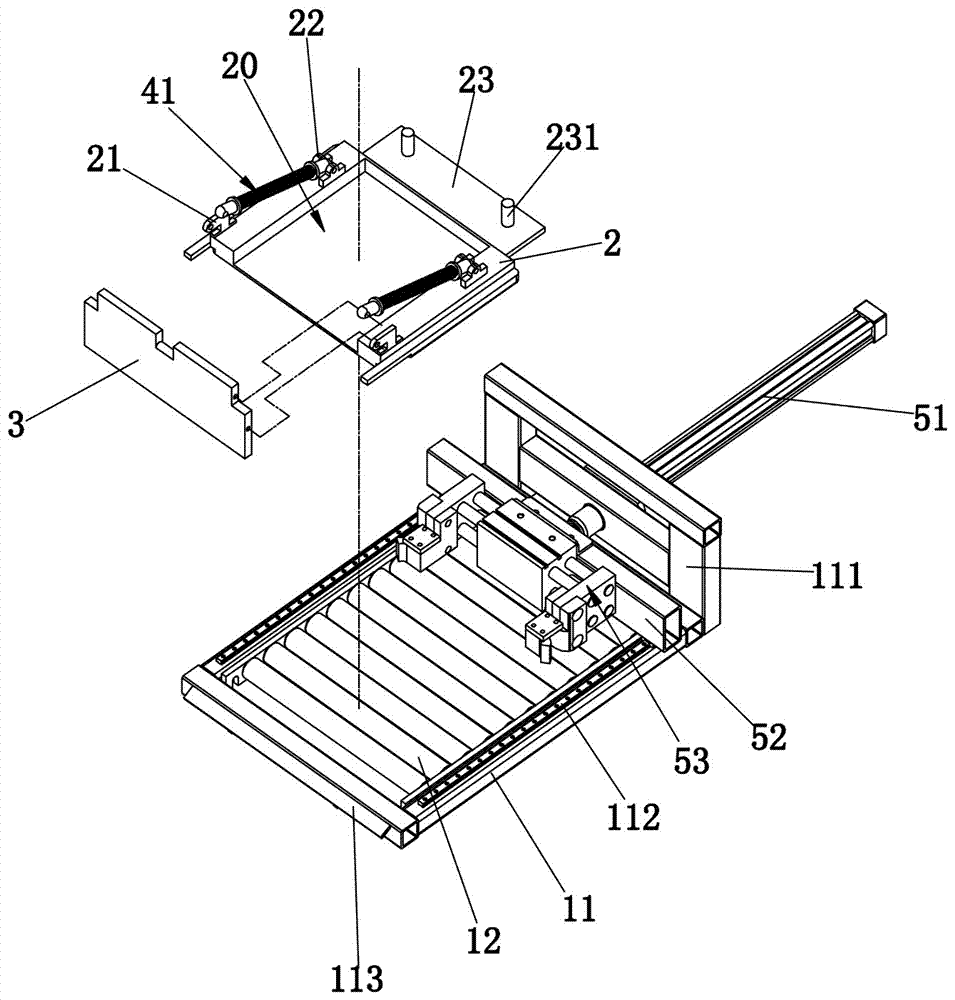

[0023] refer to figure 1 , figure 2 and image 3 , a self-opening and retrieving device, including a base 1, a tray body 2, a tray door panel 3 and a drive assembly 4, wherein the base 1 is equipped with a pushing device 5 that enables the tray body 2 to move back and forth on the base 1. The upper surface of the tray body 2 is provided with a trough 20 , and the trough 20 is provided with a feed opening at the front end of the tray body 2 , and the tray door panel 3 is openably and closably arranged at the feed opening through the driving assembly 4 .

[0024] refer to figure 1 , figure 2 and image 3 , Specifically, the pushing device 5 includes a wide air claw 53 , a cylinder 51 and a movable rod 52 . A plate 23 is provided at the rear end of the tray body 3 , and two traction posts 231 are provided on the upper surface of the plate 23 . The a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com