Steam generator control method, system and garment steamer

A technology of steam generator and control method, which is applied in the direction of steam generation method, control system, steam generation, etc., which can solve the problems of intermittent powerful steam and long waiting time for steam outlet of clothes ironing machine, so as to ensure stability and gas outlet Continuity, avoid frequent intermittent, low energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

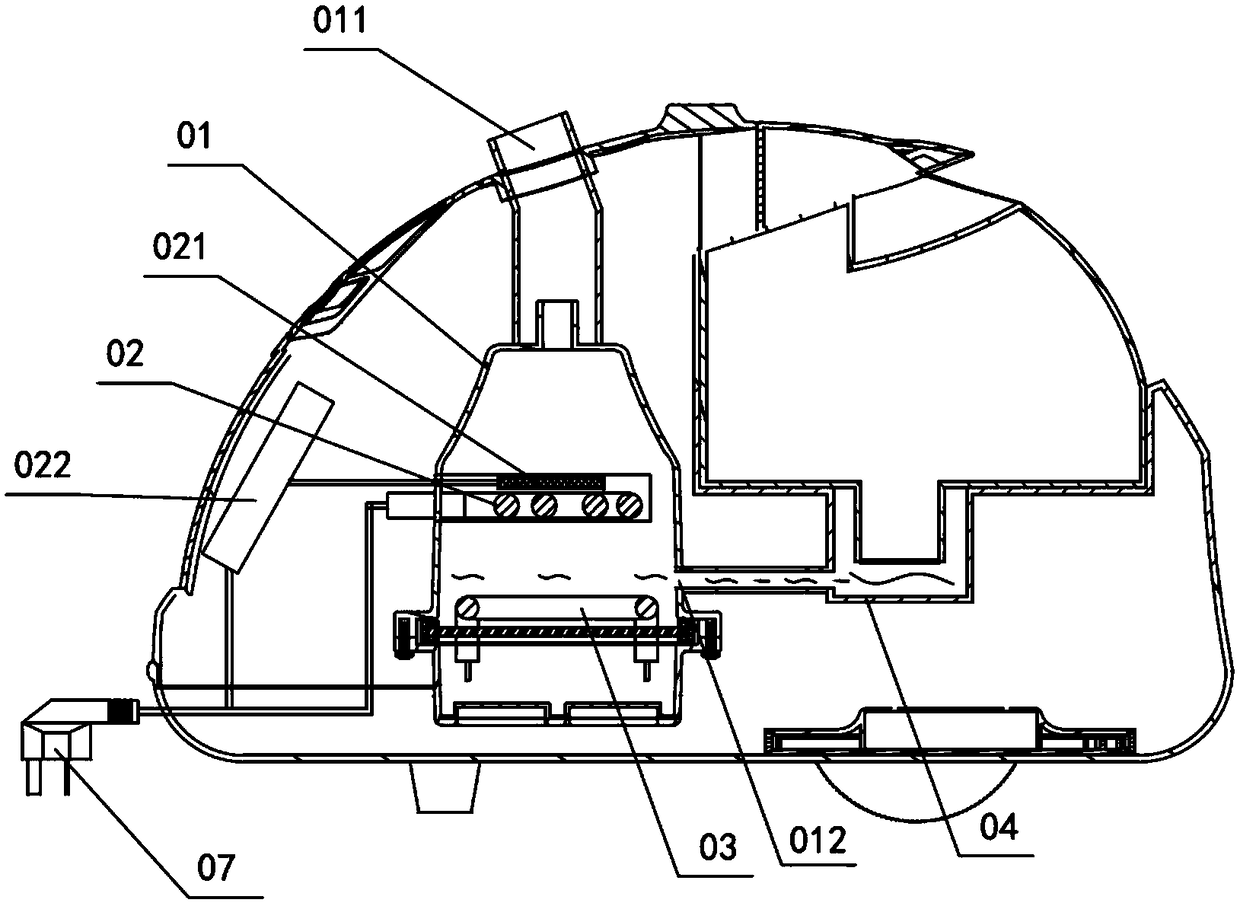

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

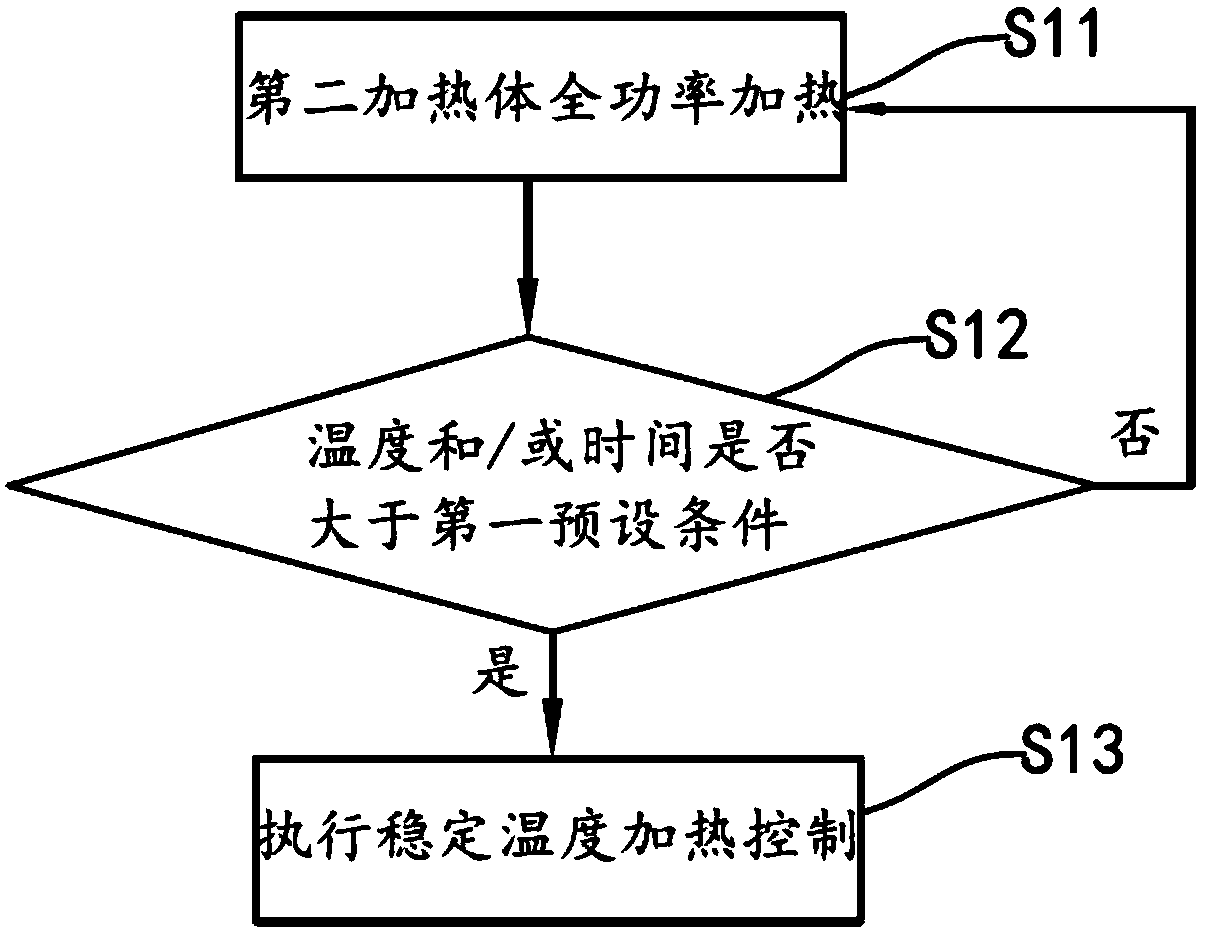

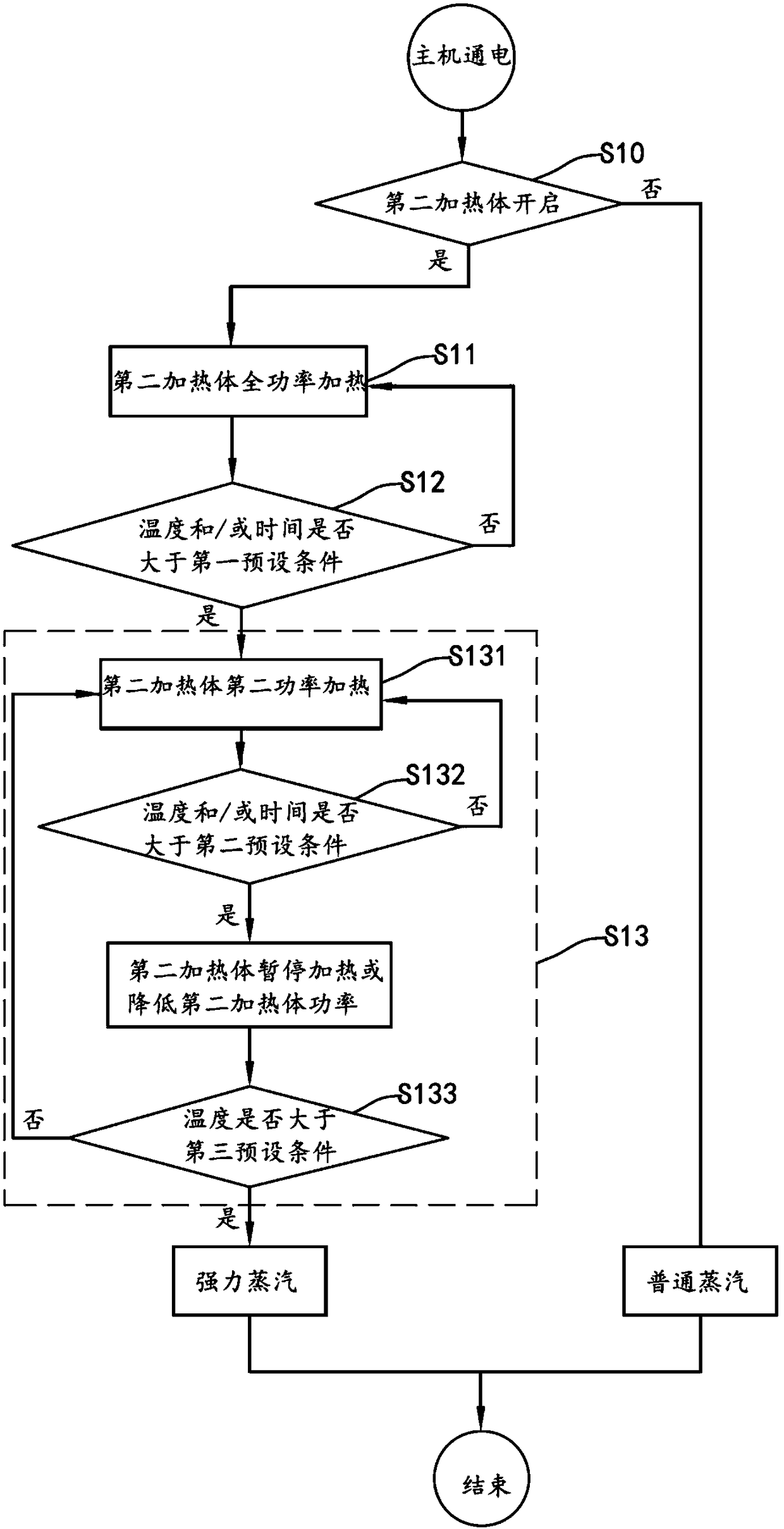

[0040] Refer to figure 1 ,

[0041] The steam generator includes a first heating body for heating water into steam, a second heating body for reheating the steam, and a controller for controlling the operation of the second heating body. The control method includes the following steps:

[0042] Step S11, after the second heating body is turned on, the controller controls the second heating body to heat according to the first power, and the first power is the full power of the second heating body;

[0043] Step S12, judging whether the temperature of the second heating body is greater than the first preset temperature T1, and / or whether the full power heating time of the second heating body is greater than the first preset time t1, if yes, execute step S13, otherwise execute step S11;

[0044] Step S13, performing heating control for stabilizing the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com