Beverage-packaging production line efficiency and machine state assessing method

A production line efficiency, packaging production line technology, applied in the field of automation systems, to achieve the effect of real-time judgment of working conditions and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

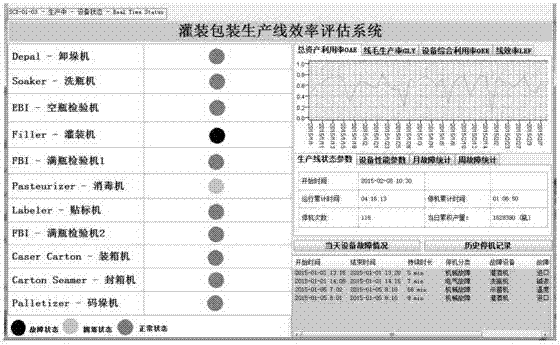

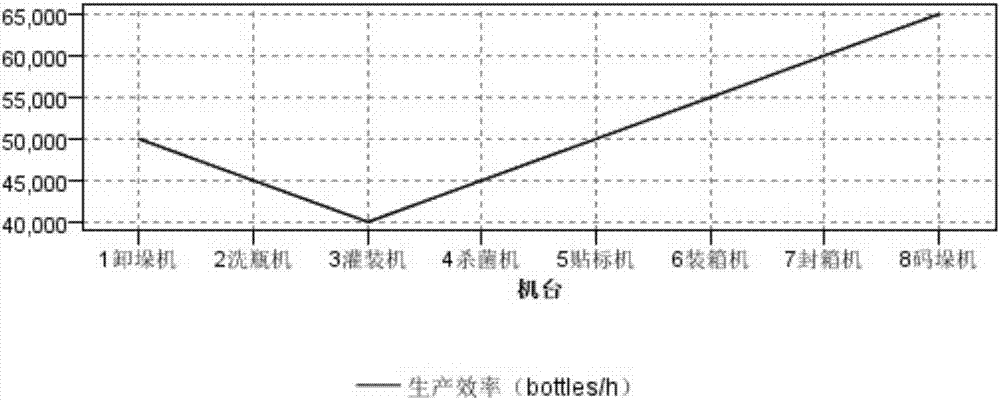

[0031] This section will specifically demonstrate how to evaluate the efficiency of the filling production line and equipment monitoring based on the above patent description. The following description is provided according to the chapters of the present invention, so that anyone skilled in the art can use the present invention to construct an efficiency monitoring system, or illustrate the implementation process proposed by the present invention. The basic principle of the present invention has been clearly defined, providing a new useful system evaluation and monitoring method for real-time evaluation and monitoring of the overall performance of the production line, the overall performance of the production line is calculated from the established data.

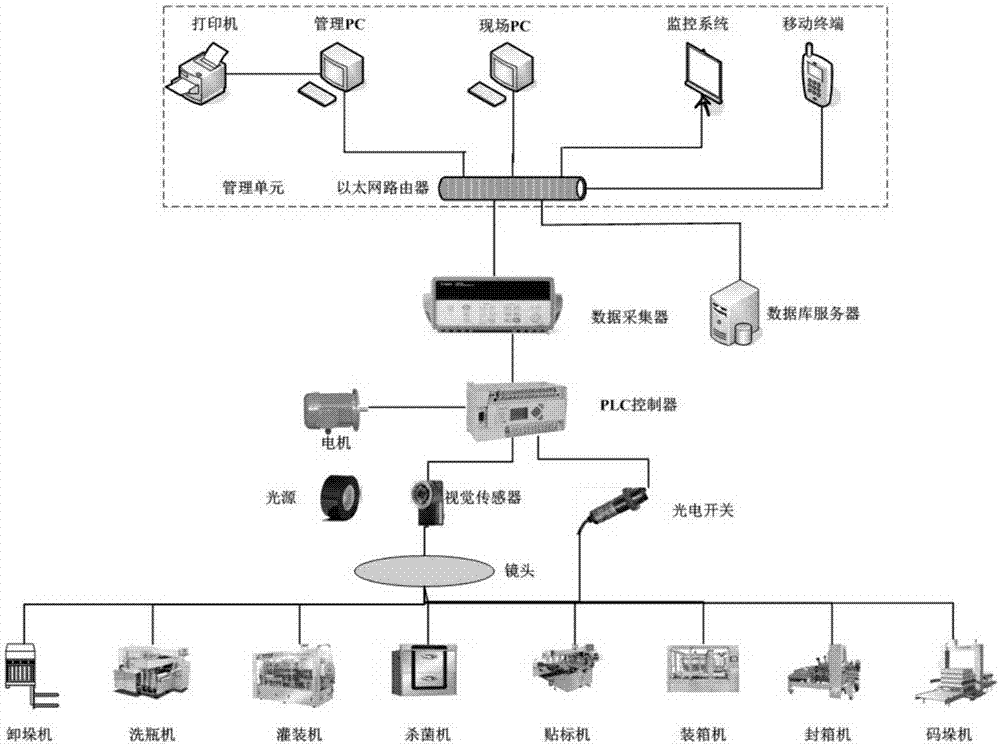

[0032] First of all, according to the layout characteristics of the filling production line, visual sensors, sensor measurement systems, photoelectric switches, photoelectric encoders and PLC controllers are arranged and inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com