Metal furniture cabinet and method for manufacturing same

A furniture cabinet and metal technology, applied in the field of furniture, to achieve the effect of reducing weight, reducing weight and reducing thermal deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings.

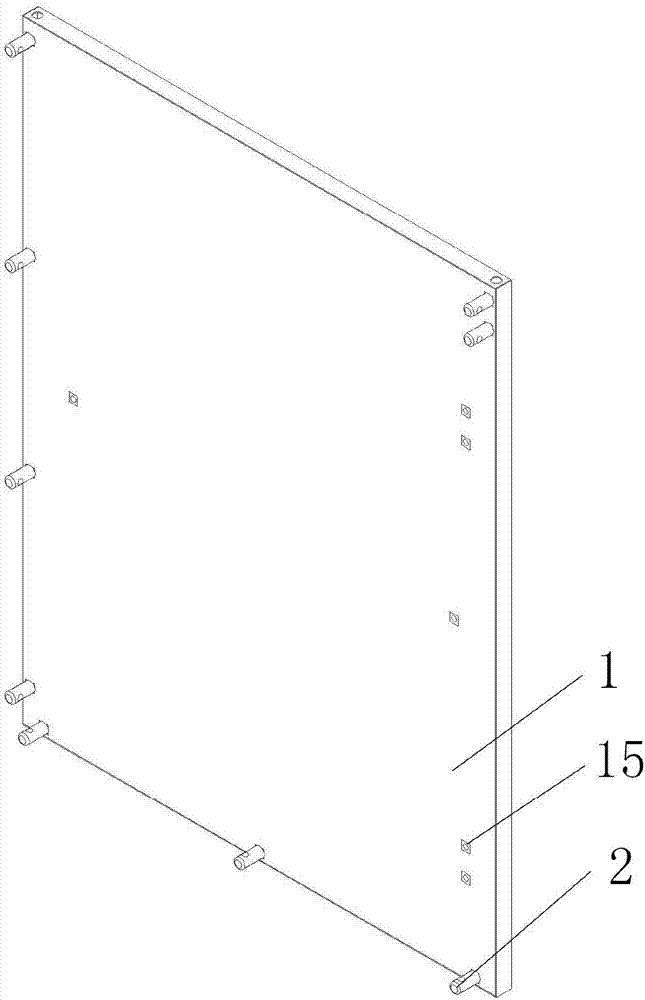

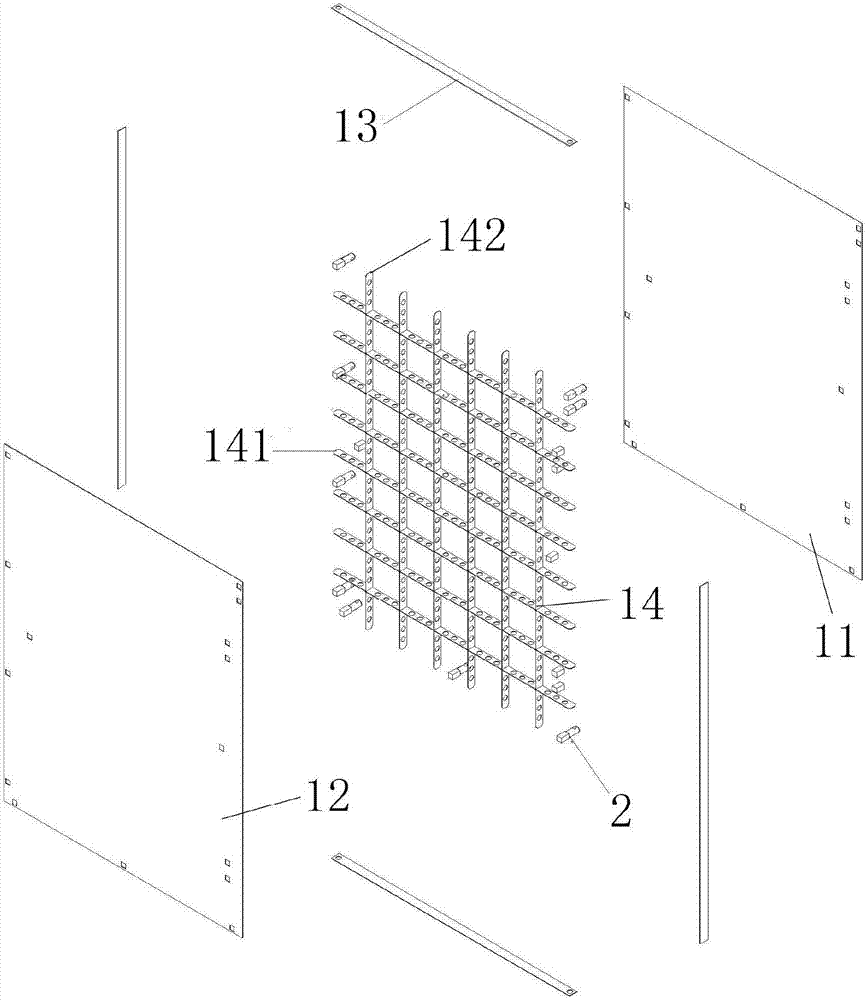

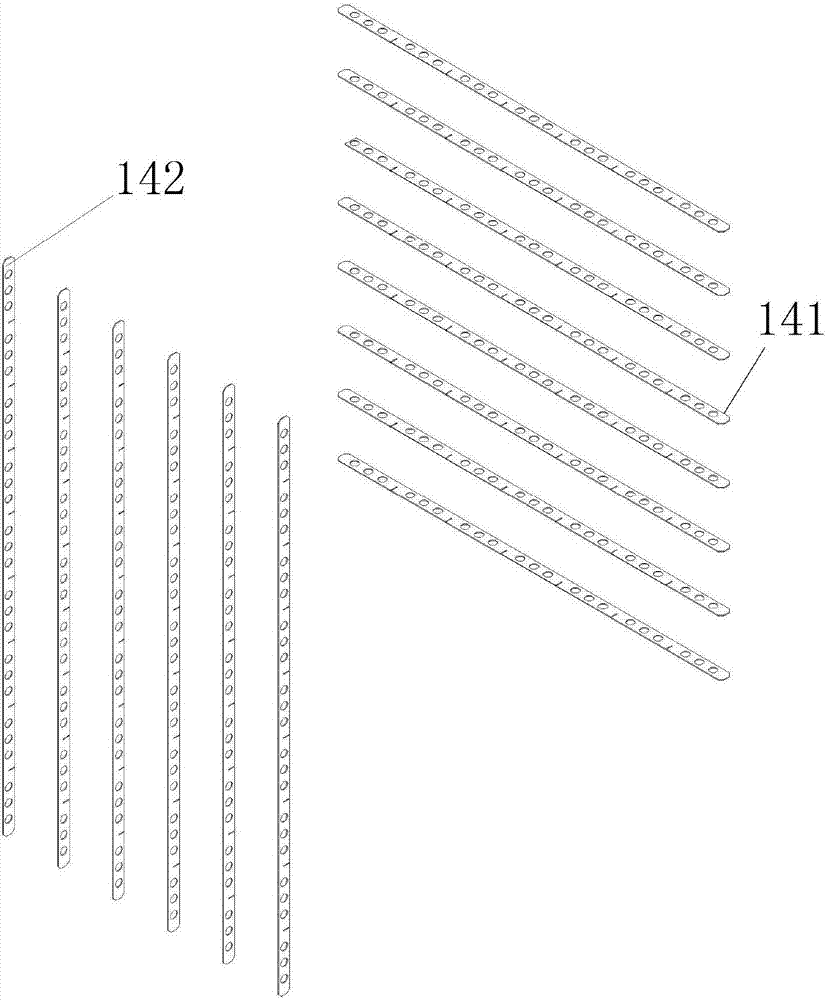

[0045] During specific implementation: if Figure 1 to Figure 6 As shown, a metal furniture cabinet includes a cabinet board 1 used for splicing and assembling metal furniture cabinets, the cabinet board includes an inner panel 11, an outer panel 12 and a side frame 13, and the inner panel 11 and the outer panel 12 are arranged at intervals, The side frame 13 is arranged between the inner panel 11 and the outer panel 12 and is assembled with the inner panel 11 and the outer panel 12 to form a closed accommodating chamber, and also includes a reinforcement structure 14 fixedly arranged in the accommodating chamber. placed in the cavity, the reinforcing structure 14 includes one or more longitudinally spaced transverse support bars 141 and one or more transversely spaced longitudinal support bars 142, the transverse support bars 141 and longitudinal The suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com