Automatic feeding machine for pot punch forming device

A stamping forming and automatic feeding technology, applied in the field of mechanical processing, can solve the problems of waste of resources, poor safety, safety accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

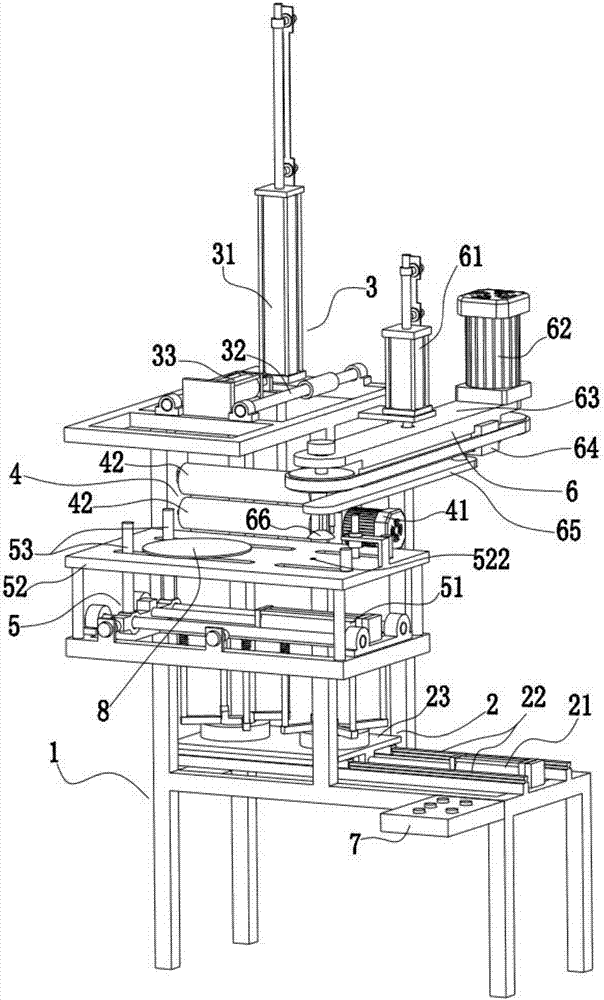

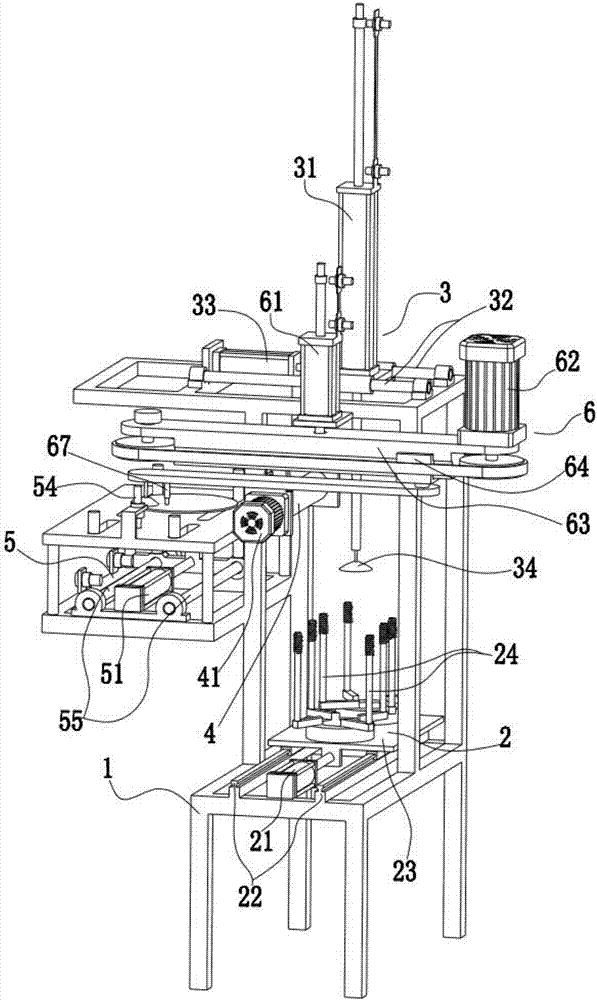

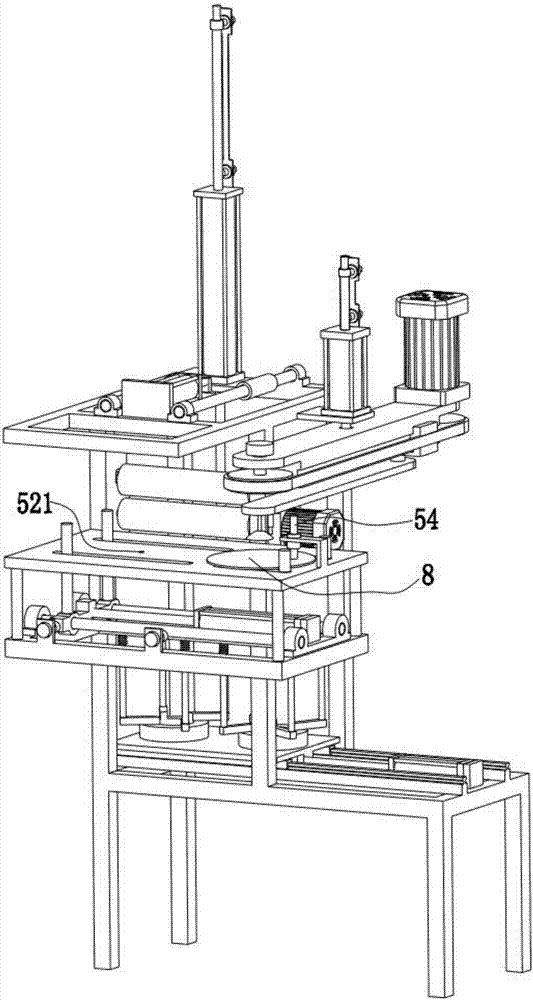

[0026] Such as Figure 1-3 As shown, an automatic feeder for stamping and forming equipment of a pot is characterized in that it includes a stand 1, a storage device 2, a vertical grabbing device 3, an oil brushing device 4, a second feeding device 5, and a third feeding device 6 and control device 7;

[0027] The storage device 2, the vertical material grabbing device 3, the oil brushing device 4, the feeding device 5 for the second time, the feeding device 6 for the third time and the control device 7 are all arranged on the platform 1; the storage device 2. The vertical grabbing device 3, the oil brushing device 4, the second feeding device 5, and the third feeding device 6 are all electrically connected to the control device 7, and the PLC program set by the control device 7 controls their coordinated work.

[0028] When working, the vertical grab device 3 grabs and transports the disc material 8 stored on the storage device 2 to the oil brushing device 4, and the disc ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com