A set-position control process of laser positioning nickel plate

A nickel plate and process technology, which is applied in the field of nickel plate production of packaging products, can solve the problems of affecting the positioning accuracy and wasting resources, and achieve the effects of easy alignment of patterns, saving design costs, and enhancing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

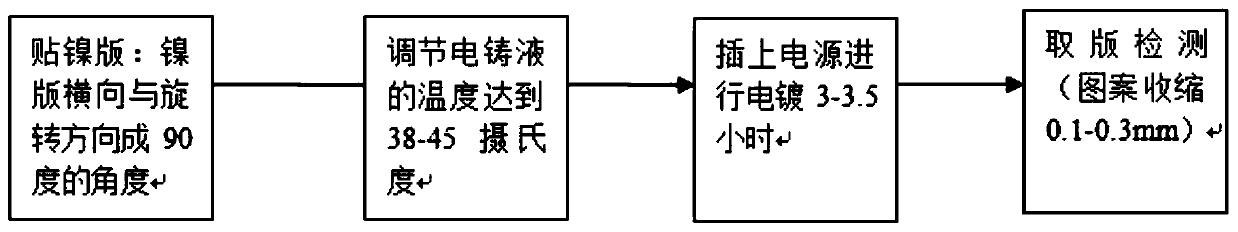

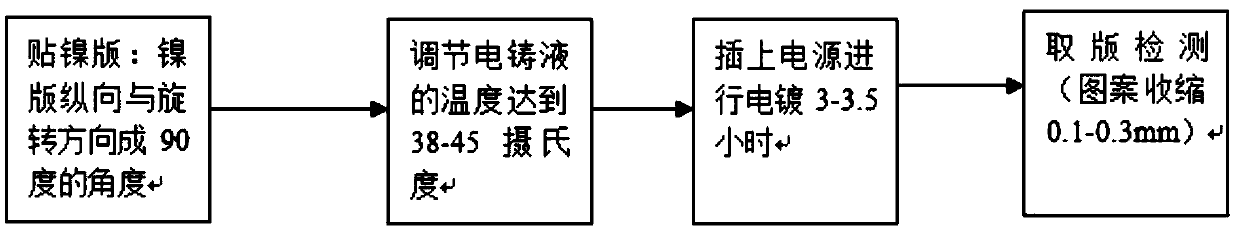

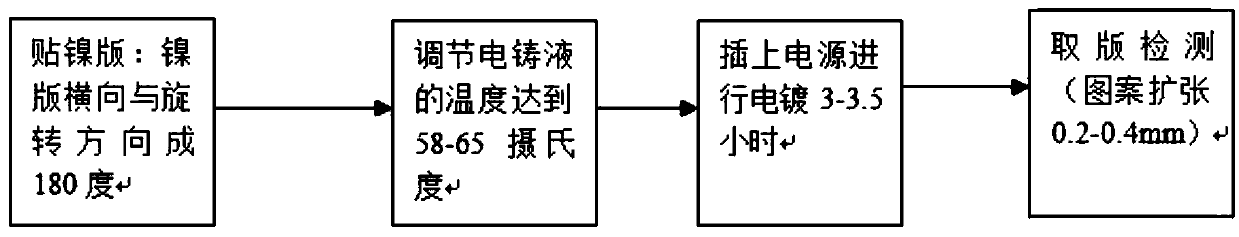

[0017] Figure 4 Show the specific implementation mode of the present invention: a set position product finds the set position deviation 0.5MM in the longitudinal direction after the nickel plate comes out, utilizes the above-mentioned technological method to deal with the deviation correction step and gathers as follows:

[0018] (1) First, the longitudinal direction of the nickel plate and the rotation direction of the mold core on the cathode rod are pasted at 180 degrees to form the cathode master plate mold core;

[0019] (2) Then adjust the temperature of the electroforming solution to 61°C;

[0020] (3) When the temperature of the electroforming solution reaches 61°C, put in the affixed cathode master mold core, plug in the power supply and start electroplating. After 3.2 hours, the thickness of the sub-plate reaches 100um and can be ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap