Rotation valve and assembly thereof

A technology of rotary valves and components, applied in valve details, multi-way valves, valve devices, etc., can solve the problems of increasing equipment processing consumables, reducing equipment work efficiency, inconvenient automatic control, etc., to reduce manufacturing costs and equipment space occupancy , Reduce production consumables, reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

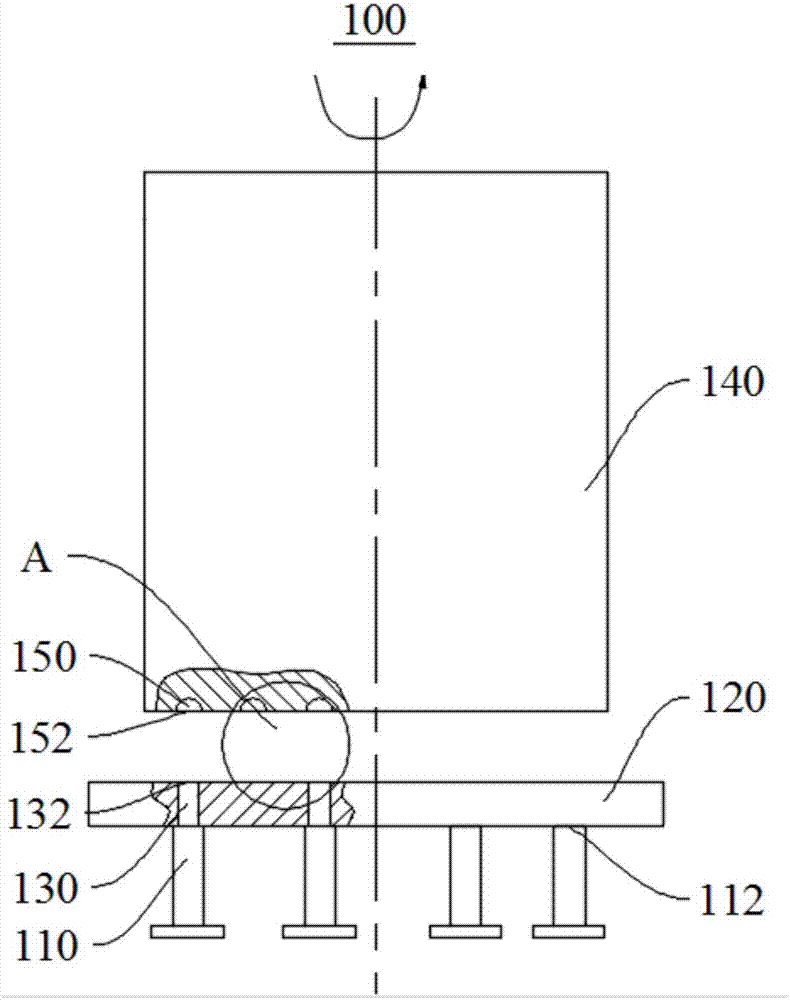

[0031] Please refer to figure 1 , this embodiment provides a rotary valve 100, which is mainly used for multi-pipeline control in chemical production. The rotary valve 100 includes a non-rotating part 120 and a rotating part 140, wherein the two opposite end faces of the non-rotating part 120 and the rotating part 140 cooperate with each other, and the rotating part 140 is rotated by itself, by virtue of the contact between the end faces of the non-rotating part 120 The mating relationship controls the state of communication between the plurality of external conduits 110 connected to the non-rotating member 120 .

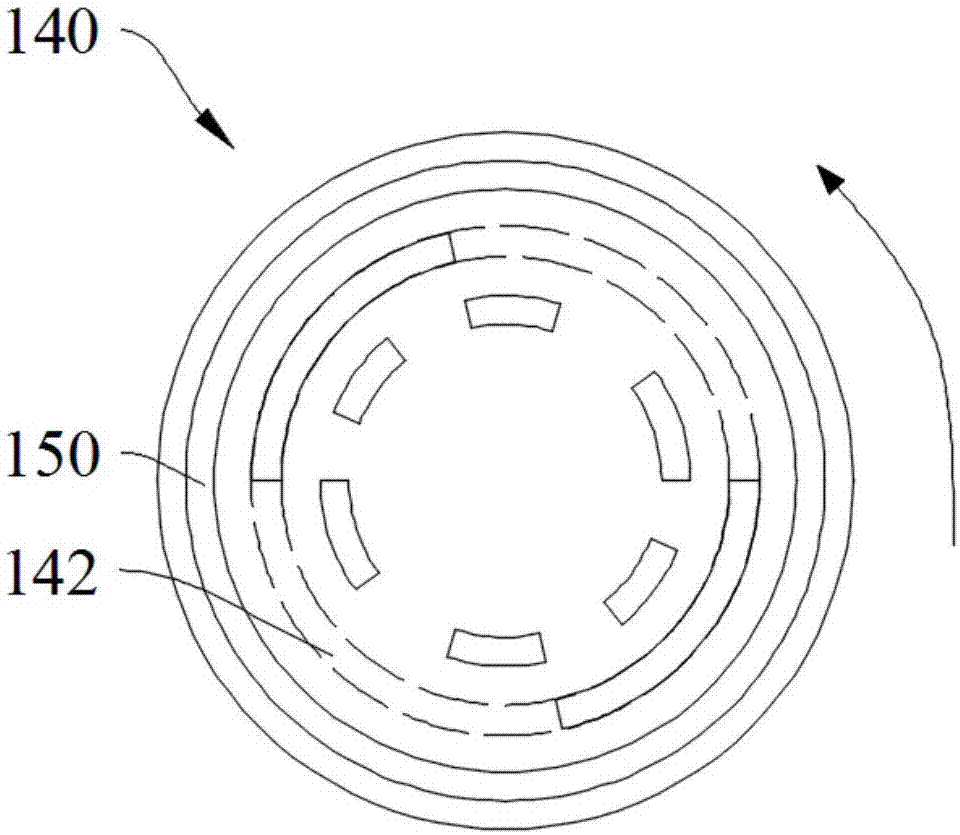

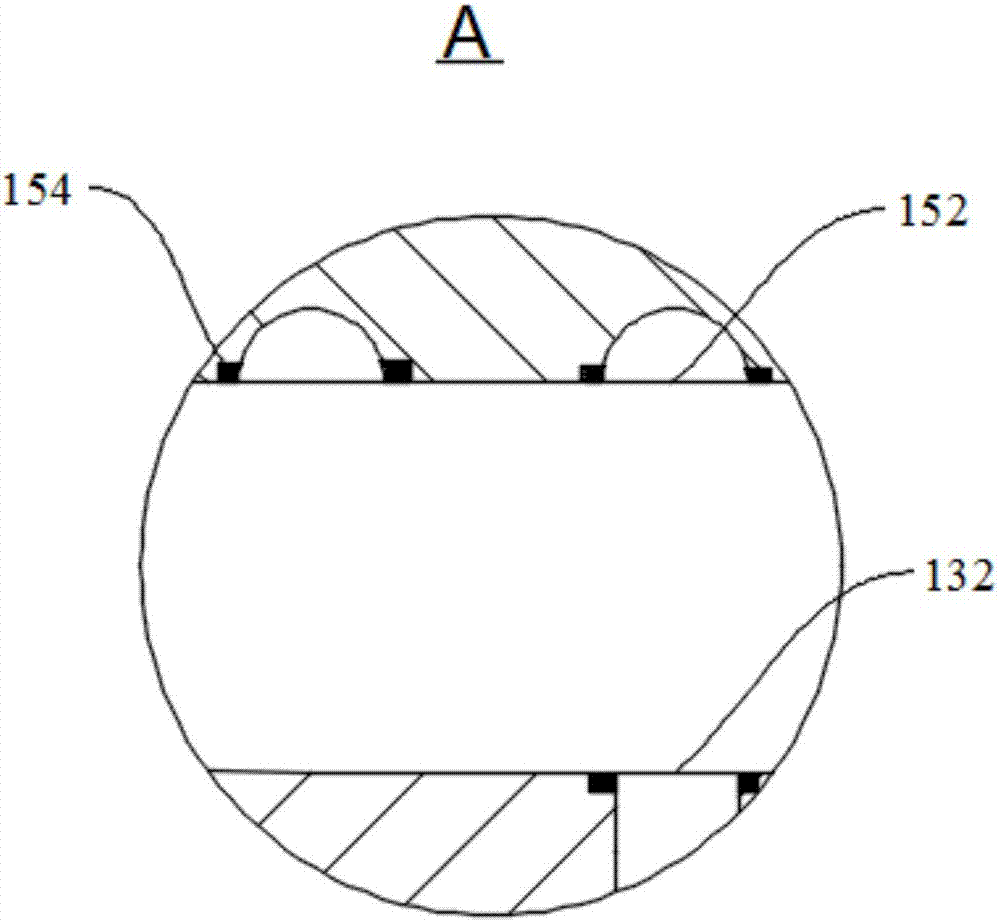

[0032] Further, the non-rotating part 120 is provided with a plurality of first flow channels 130 communicating with the external pipeline 110, the rotating part 140 is provided with a plurality of second flow channels 150 matched with the plurality of first flow channels 130, and the plurality of first flow channels 150 A communication pipe network is formed betwe...

no. 2 example

[0045] Please refer to Figure 5 , the present embodiment provides a rotary valve assembly 20, which is substantially the same as the rotary valve assembly 10 provided in the first embodiment, the difference is that the rotary valve assembly 10 of this embodiment also includes a control for controlling the rotary drive device 260 System 270.

[0046] Further, in order to improve the working efficiency and automation level of the rotary valve assembly 20 , this embodiment provides that the rotary valve assembly 20 includes a control system 270 . Specifically, the control system 270 includes a controller and a program editor communicatively connected with the controller, wherein the controller is electrically connected with the motor 262 of the rotary driving device 260 . It should be noted that the controller can not only control the rotation rhythm of the rotating part 240, but also control the rotation speed, and through the program editor, the regulation of the operation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com