Exhaust gas treatment device and exhaust gas treatment method

An exhaust gas treatment device and exhaust gas treatment technology, applied in chemical instruments and methods, separation methods, separation of dispersed particles, etc., can solve problems such as air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach >

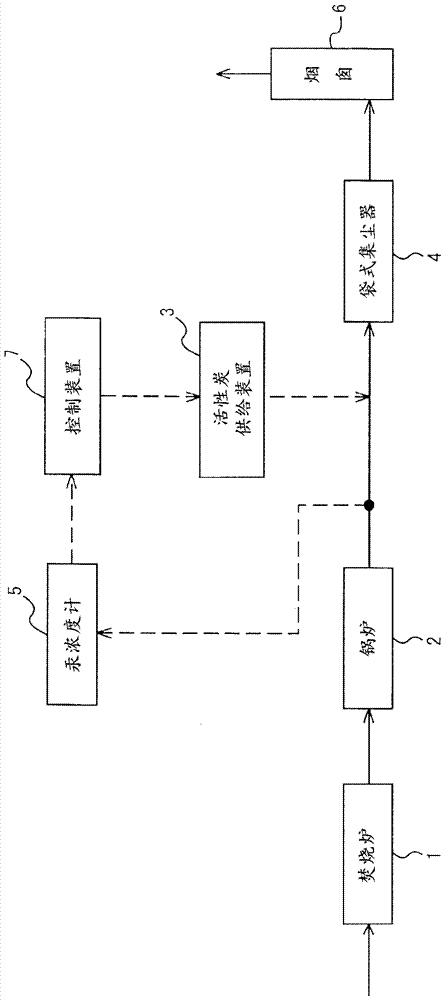

[0067] In showing the schematic structure of the device of this embodiment figure 1 Among them, in the exhaust flow path that guides the exhaust gas from the incinerator 1 to the chimney 6, the boiler 2 and the bag dust collector 4 as a dust collecting device are arranged from the upstream side. The upstream position blows into the exhaust gas flow path the activated carbon supply device 3 for adsorbing and removing mercury in the exhaust gas and the control device 7 for controlling it, and a bag filter is also installed on the downstream side of the bag filter 4, that is, a bag filter. The outlet of the dust collector 4 or the chimney 6 measures the mercury concentration meter 5 in the exhaust gas, and the above-mentioned mercury concentration meter 5 is connected to the control device 7 so that the measured value of the mercury concentration meter 5 is sent to the above-mentioned control device as an output signal. device7.

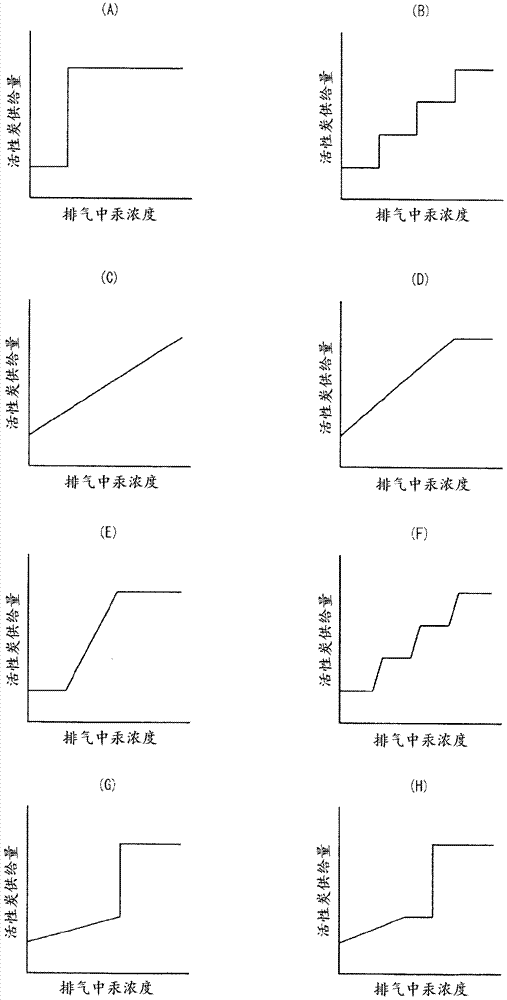

[0068] In the apparatus of the present embodimen...

no. 2 approach >

[0073] figure 2 Compared with the above-described first embodiment, the present embodiment shown is only different in the arrangement position of the mercury concentration meter 5 , and the others are the same. therefore, figure 2 in, for with figure 1 The parts that are common to those of the first embodiment are given the same symbols, and description thereof will be omitted.

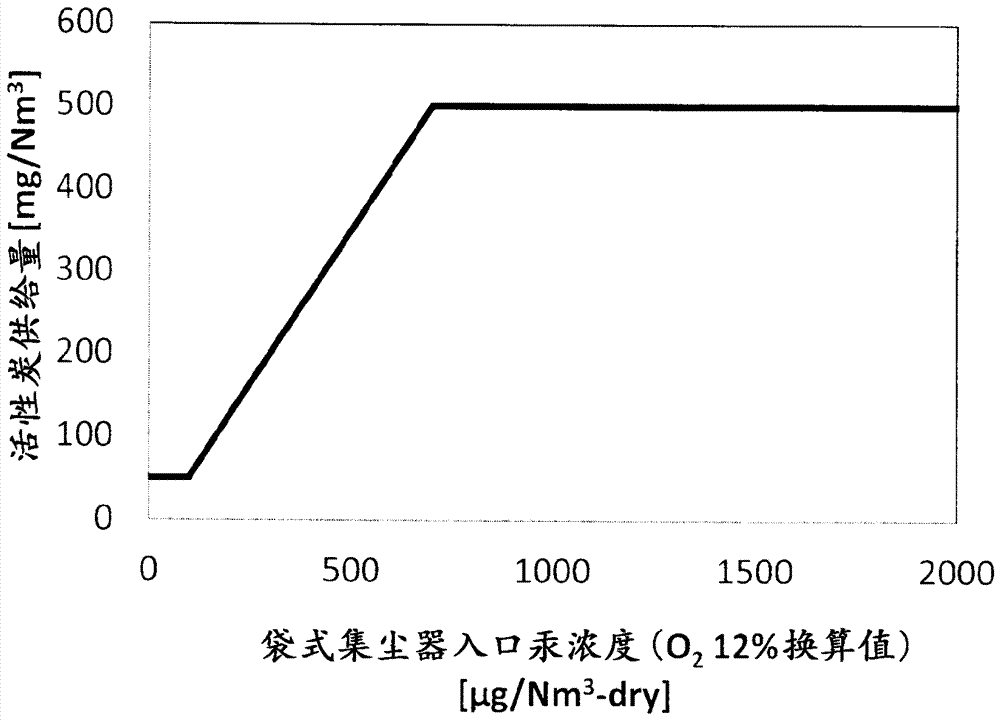

[0074] In this embodiment, if figure 2 As seen in , the mercury concentration meter 5 is arranged to measure the mercury concentration in the exhaust gas at the following positions: the downstream side of the incinerator 1 and the upstream side of the bag filter 4, and the upstream side of the activated carbon injection position of the activated carbon supply device 3 s position. In the present embodiment, the control device 7 grasps the relationship between the mercury concentration at the measurement position, the activated carbon supply amount, and the mercury concentration at the downstream...

no. 3 approach >

[0077] image 3 Compared with the above-mentioned second embodiment, the present embodiment shown has, in addition to the first mercury concentration meter 5A arranged on the upstream side of the position where the activated carbon is blown into the activated carbon supply device 3, a bag dust collector is also provided. The downstream side of the bag filter 4, that is, the outlet of the bag filter 4 or the second mercury concentration meter 5B for measuring the mercury concentration in the exhaust gas by the chimney 6, and the measured value of the second mercury concentration meter 5B is sent to the control device 7 as an output signal . Except for this point, it is the same as the second embodiment. therefore, image 3 in, for with figure 2 The parts that are common to the parts of the second embodiment are assigned the same symbols, and the description thereof will be omitted.

[0078] In this embodiment, if image 3 It can be seen that, in addition to the first merc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com