Mechanism for supplying mechanical fasteners

一种机械紧固、紧固件的技术,应用在输送机、金属加工设备、金属加工等方向,能够解决不良空气动力性和稳定性、紧固件损坏等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

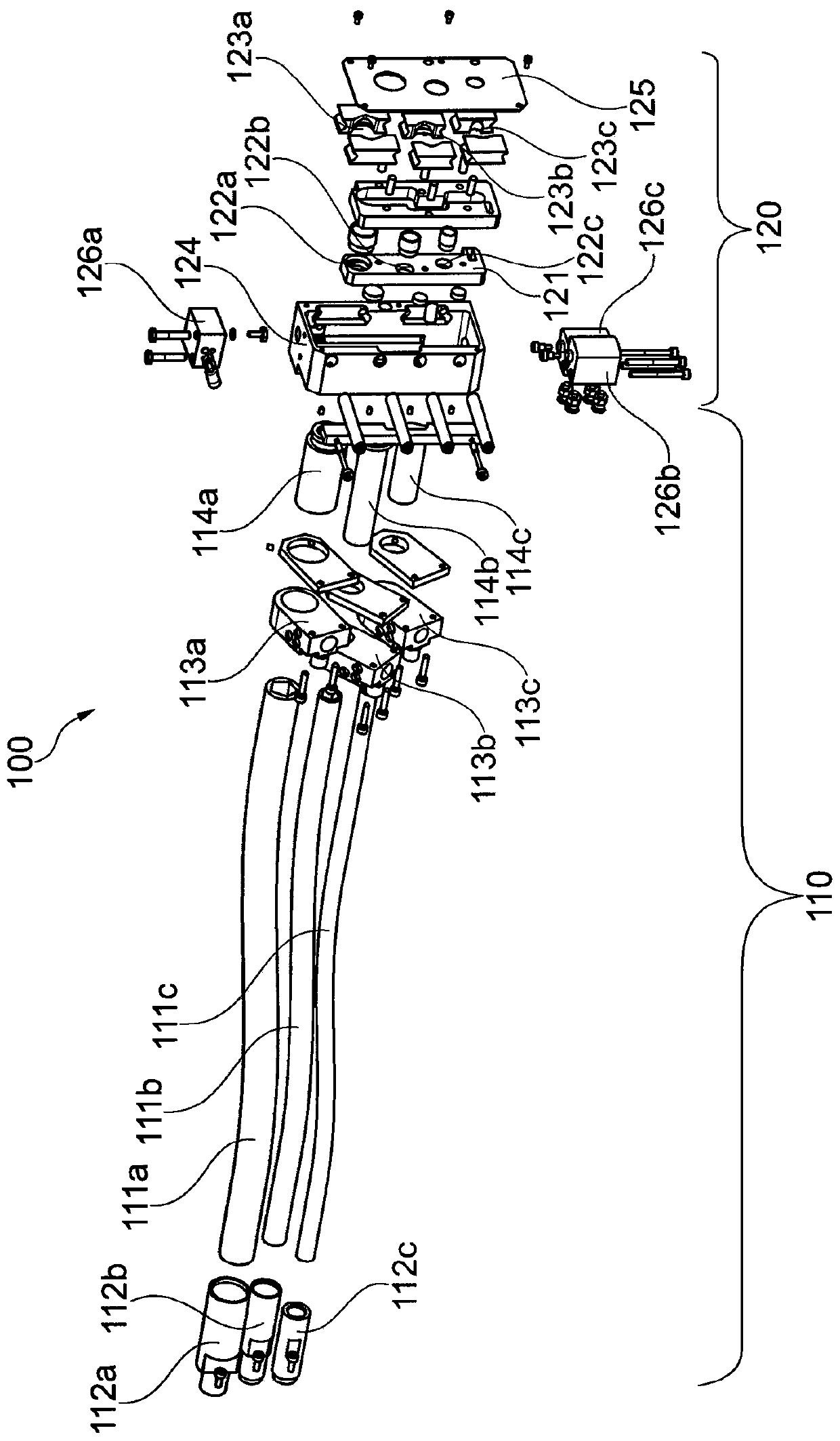

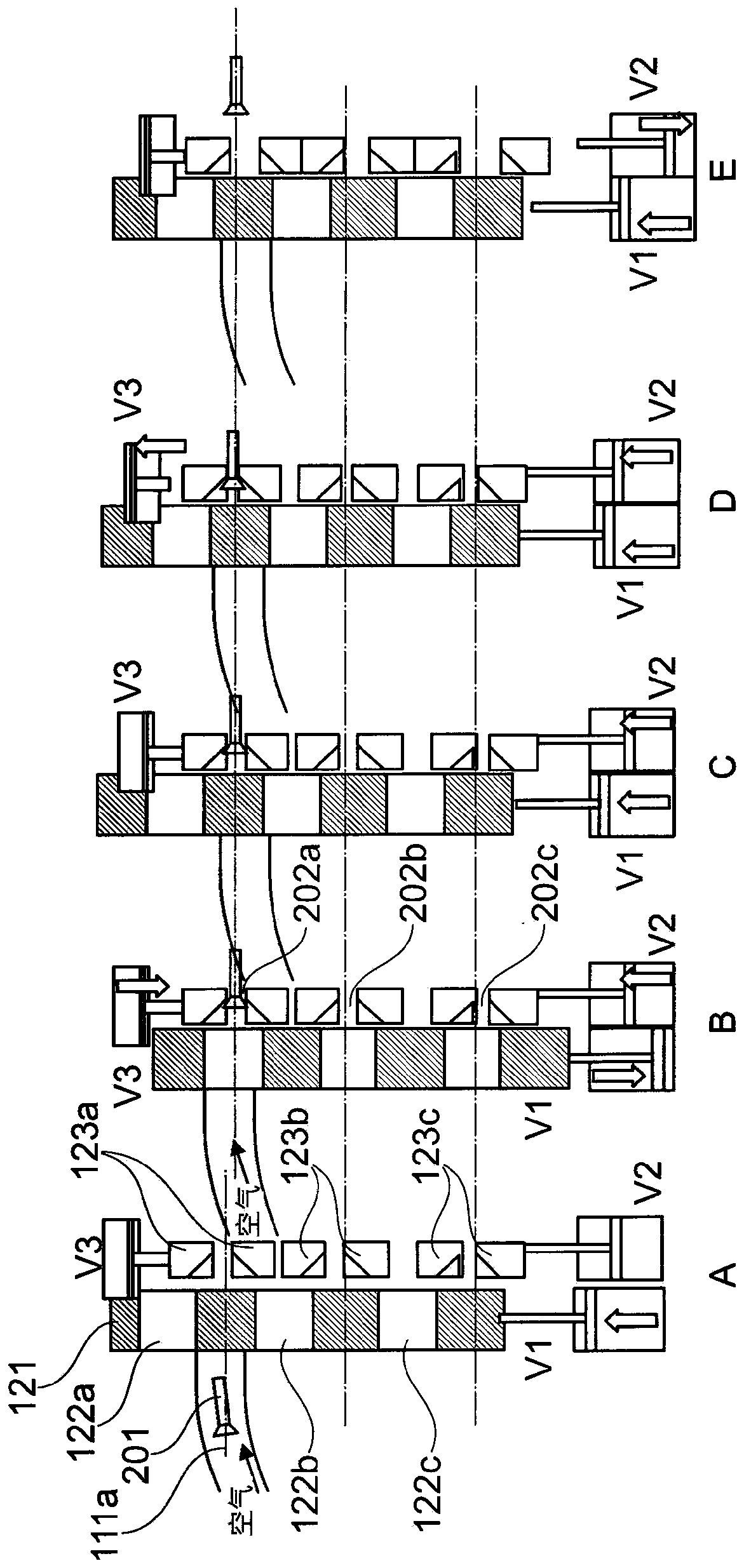

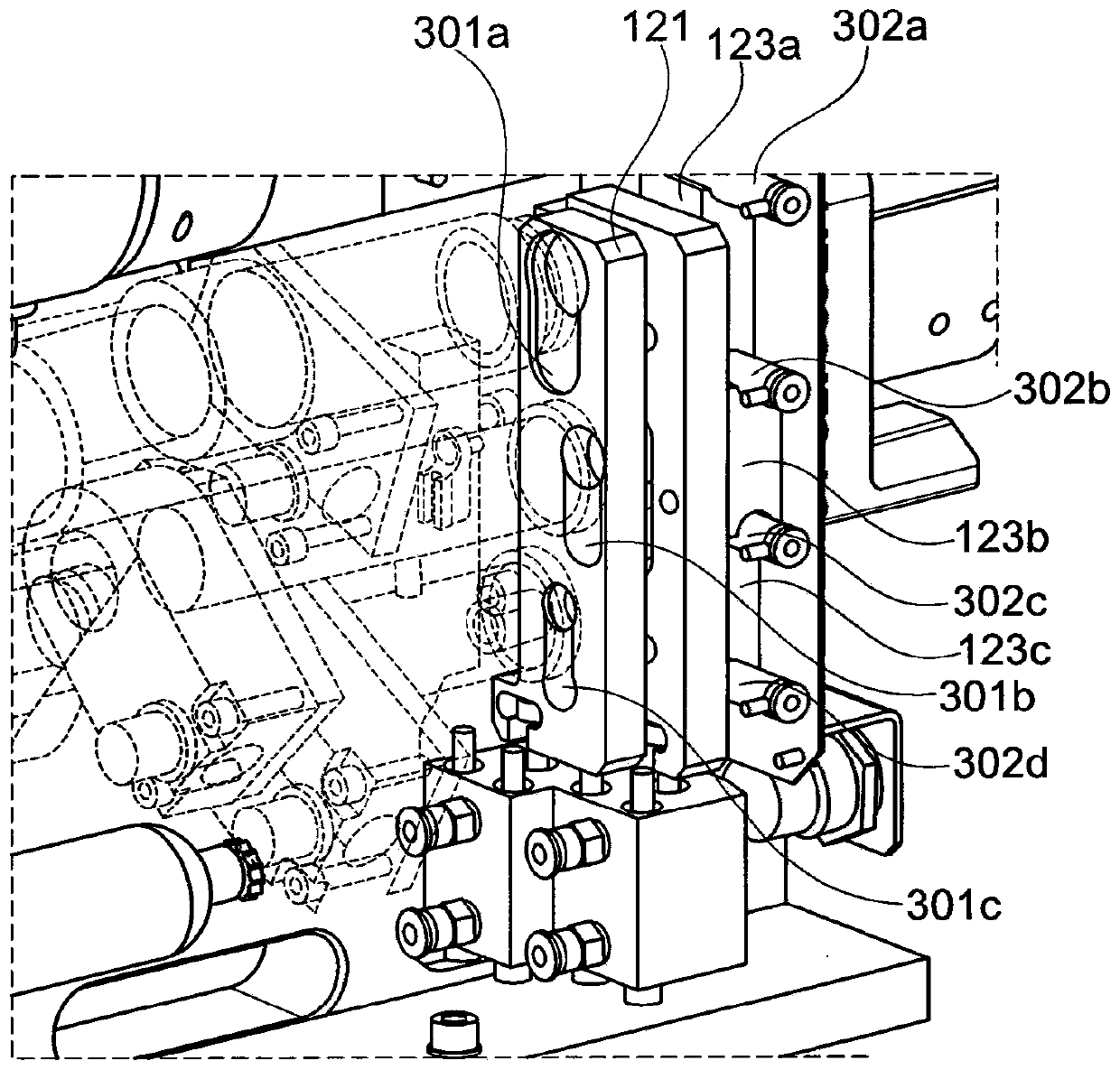

[0038] figure 1An exploded view of an exemplary feeding mechanism 100 according to the present invention is shown. The feeding mechanism 100 is suitable for feeding mechanical fasteners such as rivets, screws, bolts, and the like. The feeding mechanism 100 comprises a transport device 110 and a stopping and aligning unit 120, both shown in exploded view. The stopping and aligning unit 120 is arranged downstream of the transport device 110 , ie the mechanical fasteners to be fed first pass the transport device 110 and then the stopping and aligning unit 120 . Therefore, for figure 1 In general, fasteners will enter the feeding mechanism 100 from the left and will exit the feeding mechanism 100 on the right.

[0039] In this exemplary embodiment, figure 1 The transport device 110 shown includes three hoses 111a, 111b and 111c and corresponding retaining sheaths 112a, 112b and 112c through which the mechanical fasteners are transported. However, there can be a different numb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com