Apparatus for detecting strip steel edge crack based on correcting CPC system

A technology for detecting strips and steel edges, applied in measuring devices, using electrical devices, using optical devices, etc., can solve problems such as detection, unsuitable edge cracks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

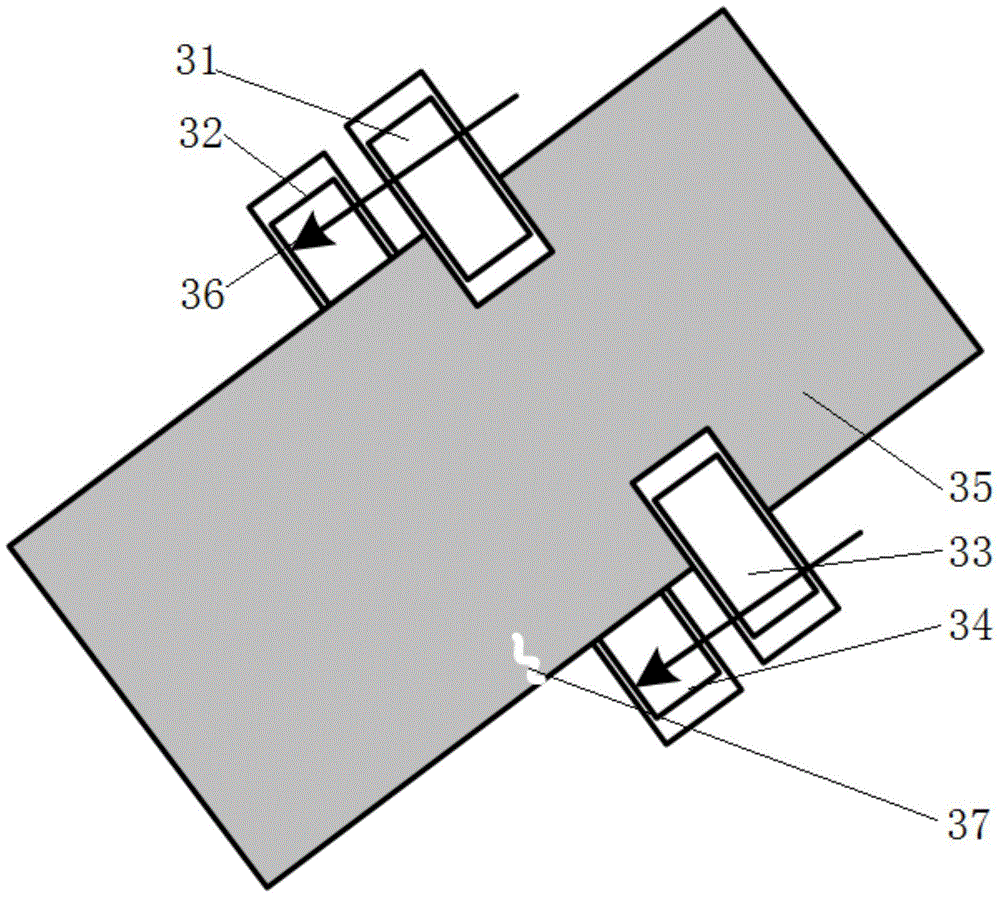

[0033] The first group of sensors and the second group of sensors used in the device for detecting strip edge cracks based on the correction CPC system provided by Embodiment 1 of the present invention are electromagnetic sensors respectively, and the first receiving end 32 is used to receive The electromagnetic signal of the second receiving end 34 is used to receive the electromagnetic signal sent from the second transmitting end 33. When the induced electromotive force detected by the first receiving end 32 and / or the second receiving end 34 suddenly jumps sharply, it is determined that The edge crack occurs at the position where the instantaneous sharp jump is caused on the strip. In this embodiment, on the side where there is a side crack (in this embodiment, the side crack is 37), the side where there is a side crack 37 is the side where the second transmitting end 33 and the second receiving end 34 are located. When the crack 37 moves between the second transmitting end...

Embodiment 2

[0036] The difference from the device for detecting strip edge cracks based on the deviation correction CPC system provided in Embodiment 1 of the present invention is that the first group of sensors used in the device for detecting strip edge cracks based on the deviation correction CPC system provided by Embodiment 2 of the present invention And the second group of sensors are optical sensors, the first receiving end 32 is used to receive the optical signal sent from the first transmitting end 31, and the second receiving end 34 is used to receive the optical signal sent from the second emitting end 33, when the first When the light intensity signal detected by the receiving end 32 and / or the second receiving end 34 has an instantaneous sharp jump, it is determined that the edge crack 37 occurs at the position on the strip 35 where the instant sharp jump occurs. In this embodiment, on the side where there is a side crack (in this embodiment, the side crack is 37), the side wh...

Embodiment 3

[0039] Improvements are made on the basis of the device for detecting strip edge cracks based on the correction CPC system provided in Embodiment 1 or Embodiment 2 of the present invention, and the device for detecting strip edge cracks based on the correction CPC system provided by Embodiment 3 of the present invention also includes an alarm Device, the alarm device is used to alarm the edge crack. Thus, it is convenient for the operator to find the edge crack of the strip in time. In the absence of an alarm device, the staff must stare at the real-time data information displayed on the signal receiving device (not shown in the figure) in real time to find the instantaneous sharp jump of the detection signal, which not only wastes human resources, but is also easy to miss , especially when the instantaneous sharp jump is near the critical value, it is difficult for the staff to judge whether there is an edge crack with the naked eye. However, when selecting the alarm device,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com