Low creep bearing and method for installing in supercharger

A supercharger and bearing technology, applied in the direction of shaft installation, bearing assembly, pumping device components for elastic fluid, etc., can solve the problem of not providing damping capacity, shear force resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Reference will now be made in detail to the examples illustrated in the accompanying drawings. Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like parts. Directional references such as "left" and "right" are for ease of reference to the drawings.

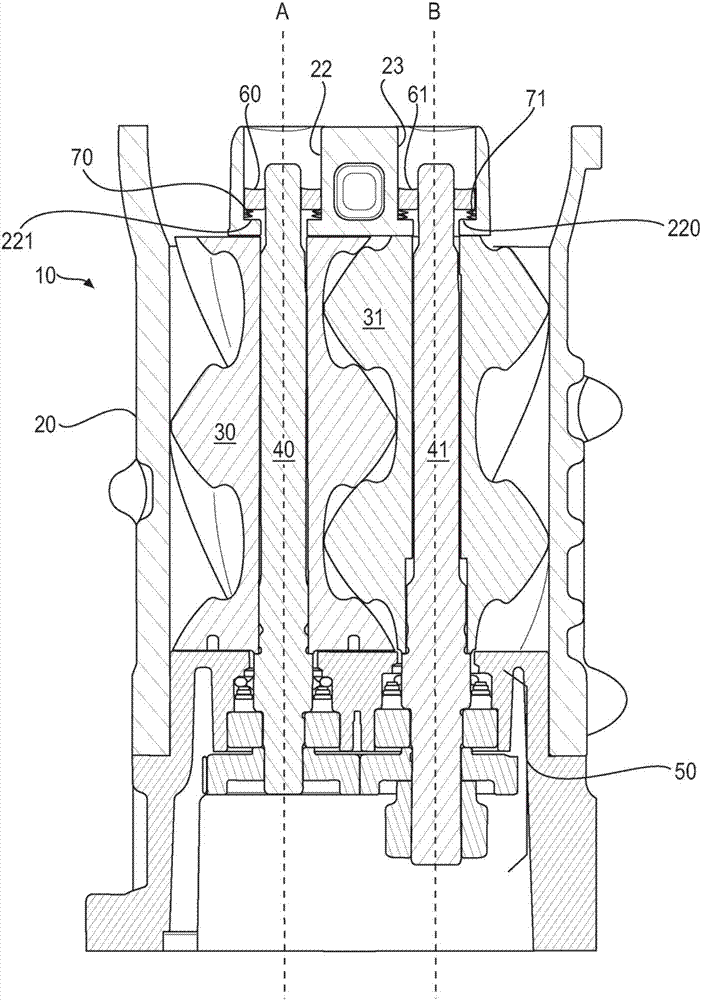

[0020] 1 shows an example of a supercharger assembly 10 including rotors 30, 31 in a housing 20. The shaft 40, 41 is positioned along the axis A, B in the center of the rotor 30, 31. The shafts 40, 41 fit into the shaft bores 22, 23 at one end of the axes A, B and fit into the transfer case 50 at the other end of the axes A, B.

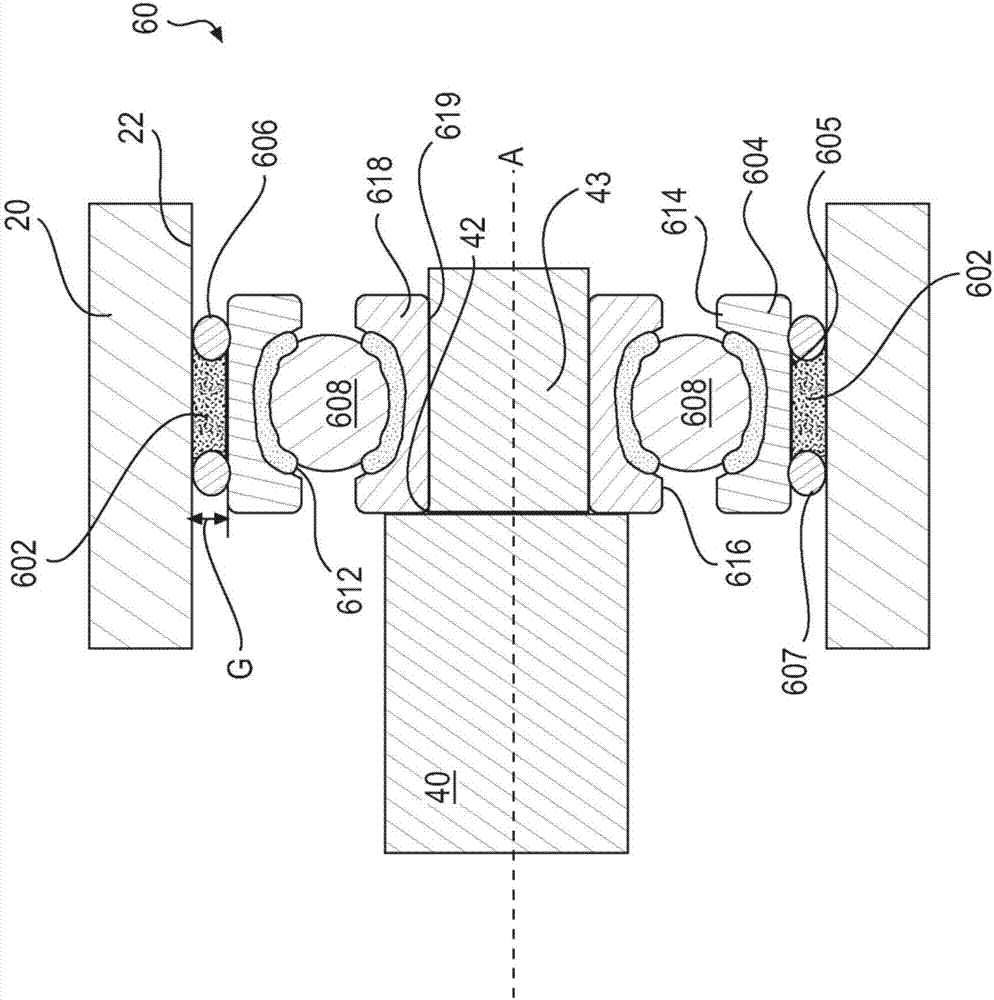

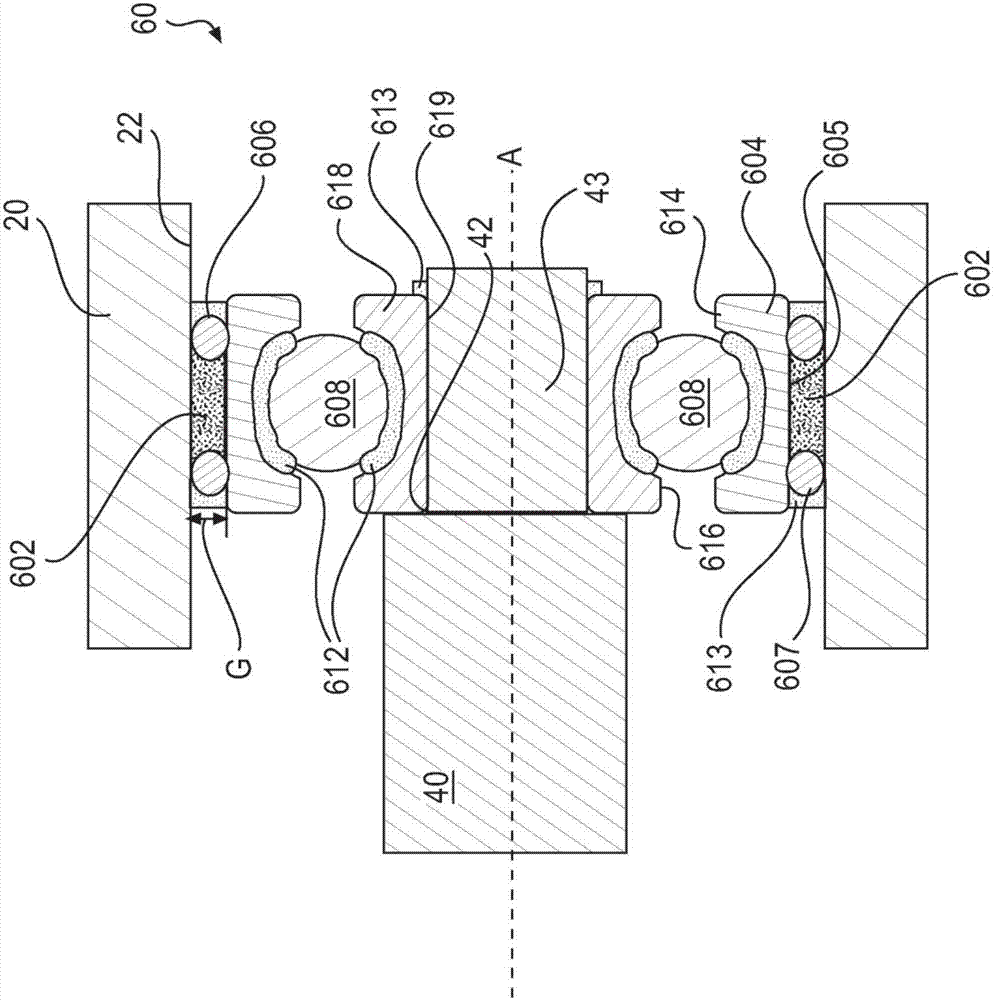

[0021] The shafts 40 , 41 fit into bearings 60 , 61 , all of which are located in the shaft bores 22 , 23 . One can fit the shaft 40 , 41 into the bearing 60 , 61 before or after placing the shaft 40 , 41 in the shaft hole 22 , 23 . For example, one may first fit the first bearing 60 onto the first shaft 40 and then slip fit the first sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com