Multi-degree-of-freedom precision positioning fixture based on micro-texture laser preparation of ball-end milling cutter

A ball end milling cutter and precise positioning technology, applied in the field of mechanical processing, can solve the problems of reduced processing efficiency and low positioning accuracy, and achieve the effect of improving the processing efficiency of microtexture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

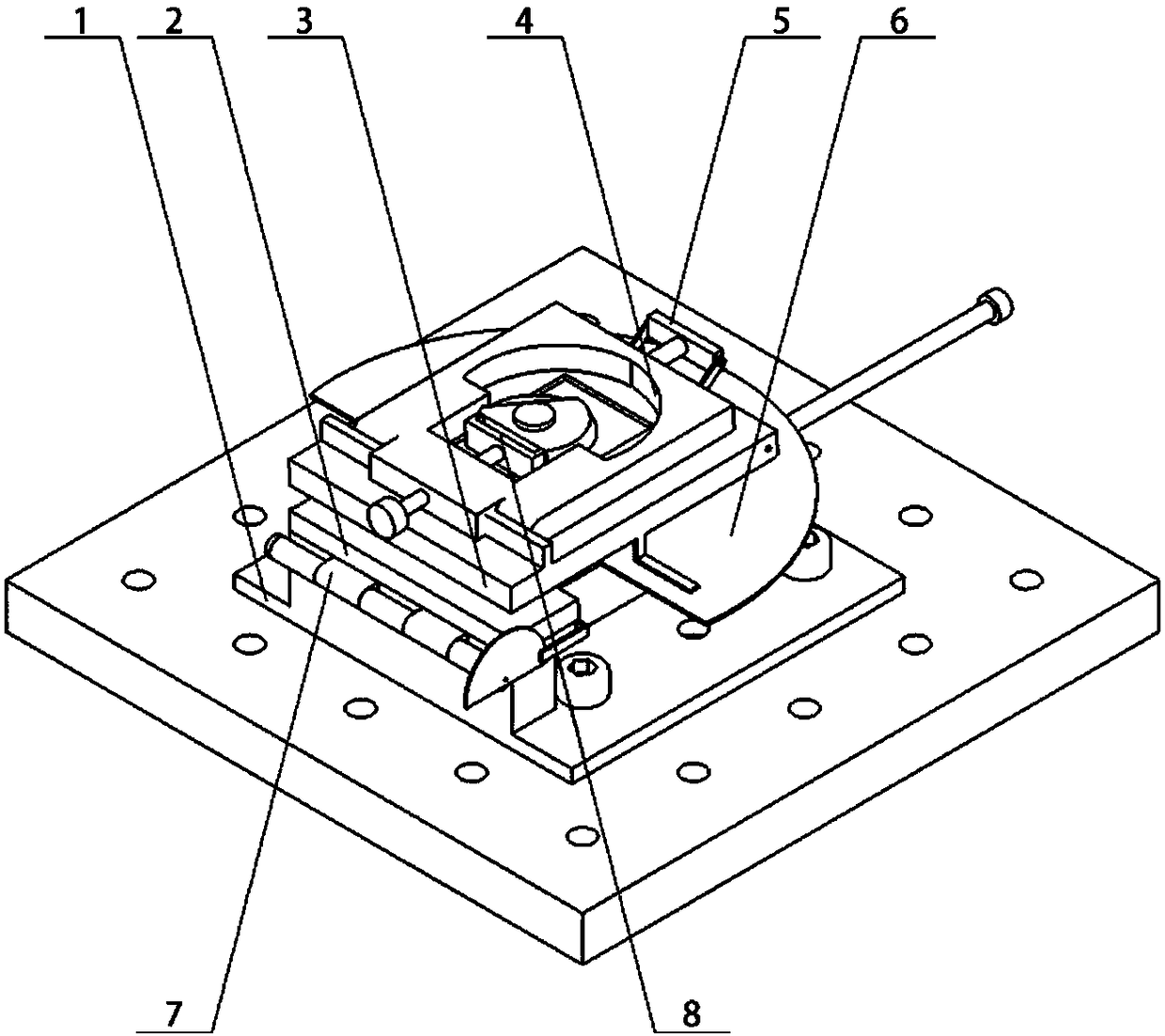

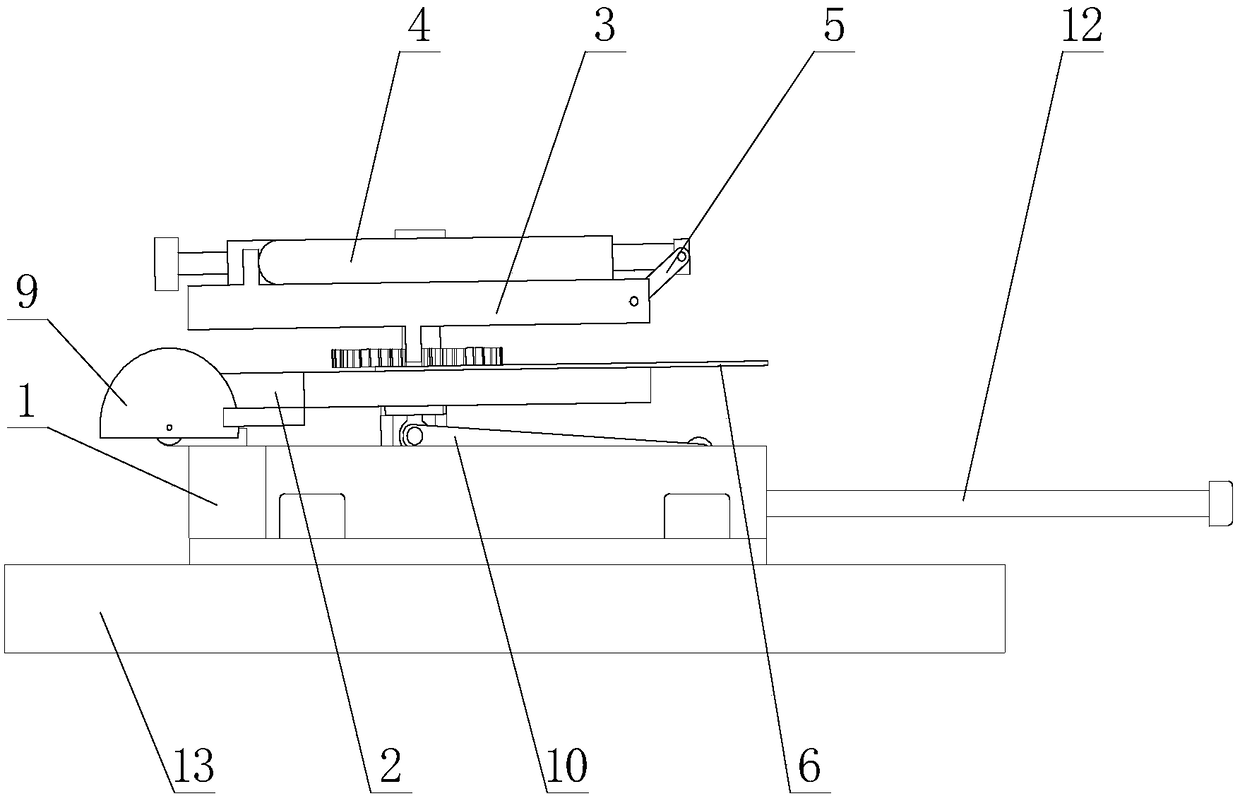

[0010] Embodiment 1: Combining Figure 1 to Figure 3 This embodiment will be described. The multi-degree-of-freedom precision positioning fixture based on ball-nose milling cutter microtexture laser preparation described in this embodiment includes a fixed base 1, a rotating base 2, a flipping drive assembly, a rotating drive assembly, a rotating plate 3, and a clamping body. 4. The connecting plate 5, the hinge 7 and the fixing mechanism 8, the fixed base 1 is installed on the working table 13 of the marking machine, one end of the rotating base 2 is connected with one end of the fixed base 1 through the hinge 7, and the lower surface of the rotating base 2 passes through The overturning drive assembly is connected to the upper surface of the fixed base 1, the rotating plate 3 is installed on the upper surface of the rotating base 2 through the rotating drive assembly, and the clamping body 4 is arranged on the upper surface of the rotating plate 3. One end is connected with ...

specific Embodiment approach 2

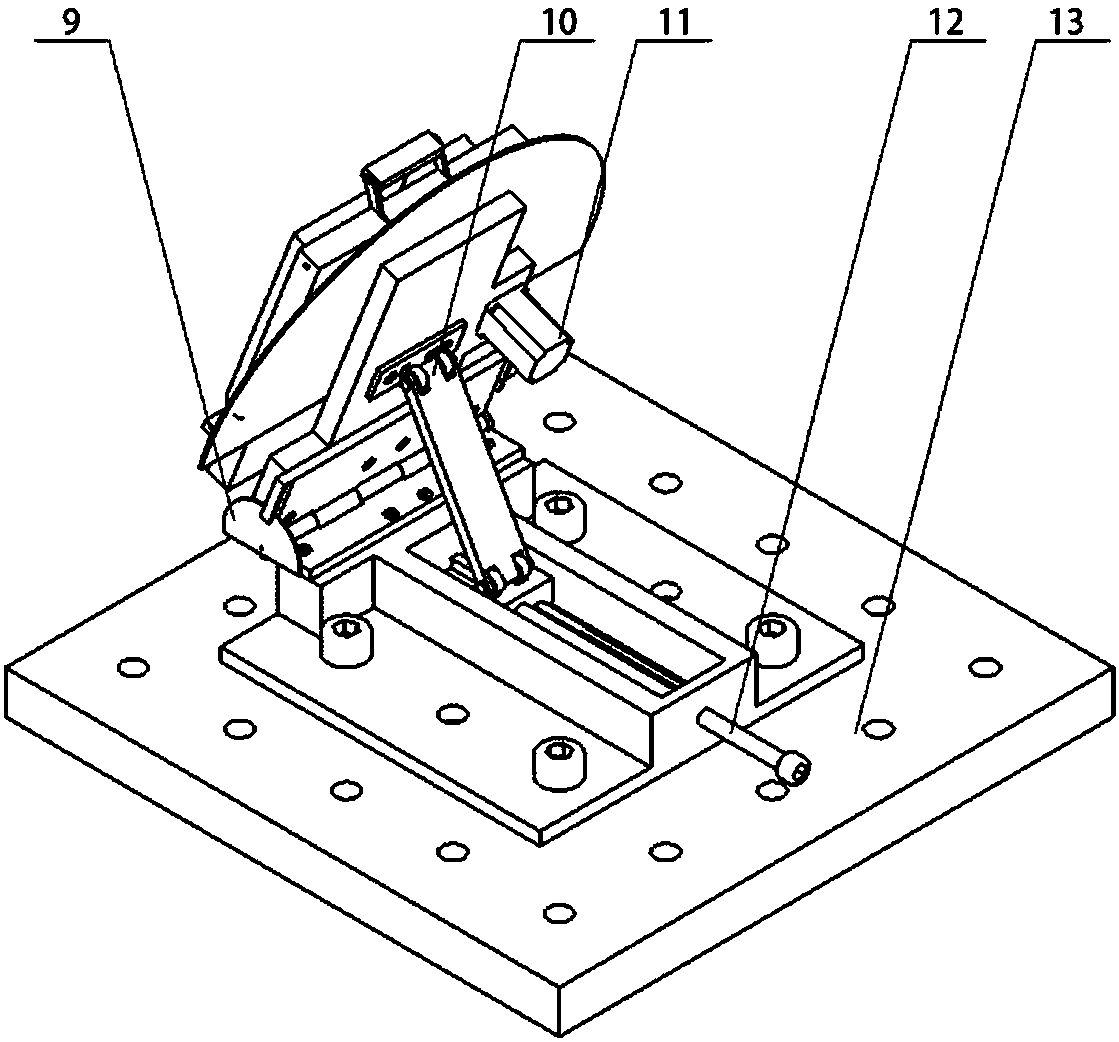

[0011] Specific implementation mode 2: Combining Figure 1 to Figure 3 Describing this embodiment, the inversion drive assembly of the multi-degree-of-freedom precision positioning fixture based on the micro-textured laser preparation of the ball-end milling cutter described in this embodiment includes a support plate 10 and an adjustment bolt 12 , and the upper end of the support plate 10 is connected to the rotating base 2 . The lower surface is hinged, the lower end of the support plate 10 is arranged in the chute 1-1 on the upper surface of the fixed base 1, and the lower end of the support plate 10 can move linearly along the chute 1-1, and the end of the adjusting bolt 12 passes through the sliding groove 1-1. The groove 1 - 1 is connected to the lower end of the support plate 10 . Other components and connection relationships are the same as in the first embodiment.

specific Embodiment approach 3

[0012] Specific implementation three: combination Figure 1 to Figure 4 Describing this embodiment, the rotary drive assembly of the multi-degree-of-freedom precision positioning fixture based on the ball-nose milling cutter micro-textured laser preparation described in this embodiment includes a stepping motor 11 , a first gear 14 , a second gear 15 and a rotating shaft 16 , the upper end of the rotating shaft 16 is connected to the lower surface of the rotating plate 3 through the rotating base 2, the first gear 14 is sleeved on the rotating shaft 16, the second gear 15 is sleeved on the rotating shaft of the stepping motor 11, the first gear 14 It meshes with the second gear 15 . Other components and connection relationships are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com