Argon blowing connector convenient to detach and assemble

A threaded connection and connected pipe technology, applied in the direction of pipe/pipe joint/pipe fitting, threaded connection, pipe damage/wear prevention, etc., can solve the problem that the outlet pipe is easy to fall into molten steel, and it is inconvenient to disassemble and assemble.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

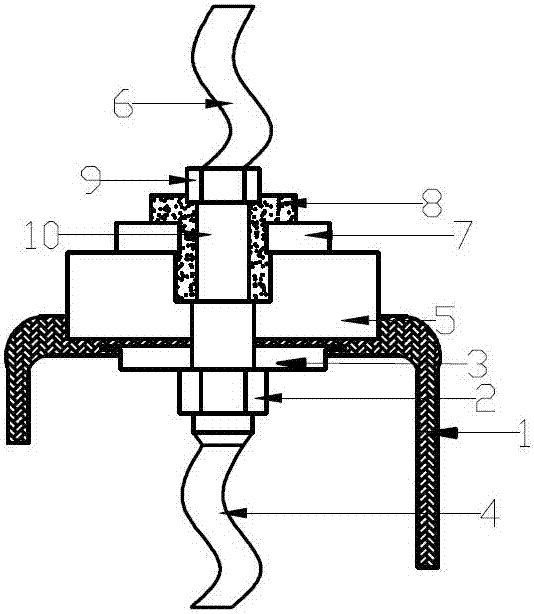

[0015] An argon blowing joint that is easy to disassemble and assemble, including a support plate 1, a lower connecting pipe 2, a T-shaped limiting plate 3, an air outlet pipe 4, a limiting round table 5, an air inlet pipe 6, a T-shaped round table 8, an upper connecting pipe 9 and The central tube 10; the cross section of the support plate 1 is U-shaped, and the limiting round table 5 is detachably and fixedly connected to the upper surface of the supporting plate 1, and the center of the limiting round table 5 is provided with a round hole matching the T-shaped round table 8 hole, the bottom wall of the support plate 1 is provided with a T-shaped slot matching the T-shaped limiting plate 3, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com