High-heat-dissipation type computer cable

A computer cable, high heat dissipation technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of unsatisfactory users and unsatisfactory comprehensive performance of computer cables, so as to prevent heat from concentrating inside the cable, speed up heat transfer, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

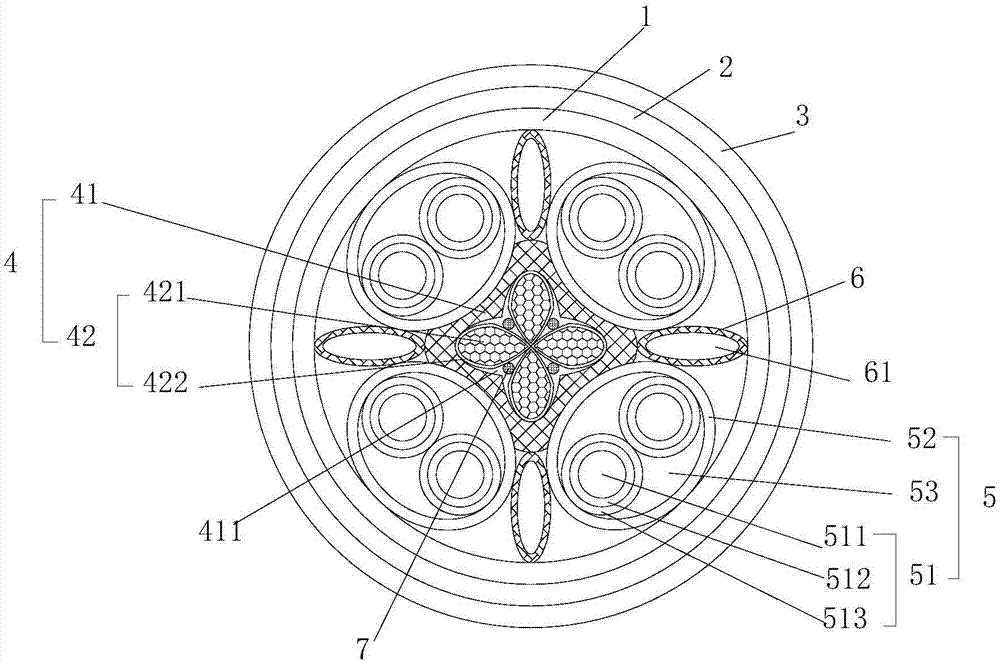

[0017] refer to figure 1 , the present invention proposes a high heat dissipation computer cable, including a wire core and an inner sheath layer 1, a shielding layer 2, and an outer sheath layer 3 wrapped in turn outside the wire core, and the wire core includes a central wire core 4 and N outer wire cores 5, N≥3, where:

[0018] The central core 4 is arranged at the center of the cable. The central core 4 includes an elastic skeleton 41 and a plurality of central conductors 42. The elastic skeleton 41 has a regular N-shaped cross-section and each side of the elastic skeleton 41 is provided with a recess toward the inner side of the cable. The arc-shaped groove, the elastic skeleton 41 is provided with a central cavity 411, a plurality of central conductors 42 are distributed in the central cavity 411 and a plurality of central conductors 42 are all close to the inner circumference of the elastic skeleton 41, the thickness of the central conductors 42 From the end close to t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap