Preparation method of anion resin adsorbent for bilirubin

An anion resin and adsorbent technology, applied in the field of bilirubin anion resin adsorbent and its preparation, can solve the problems of inability to expose, affect bonds and efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

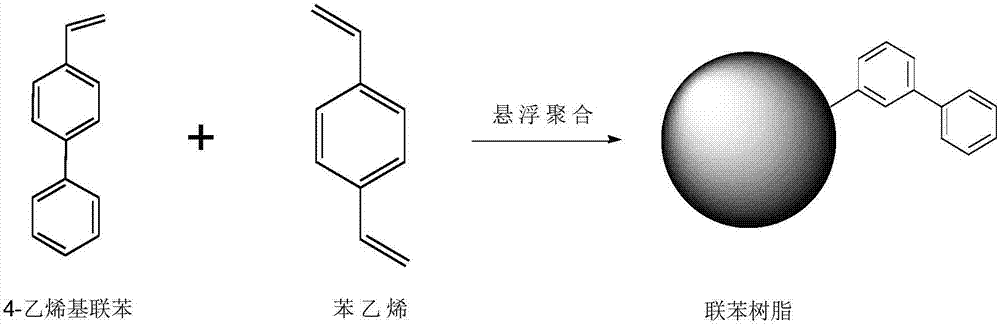

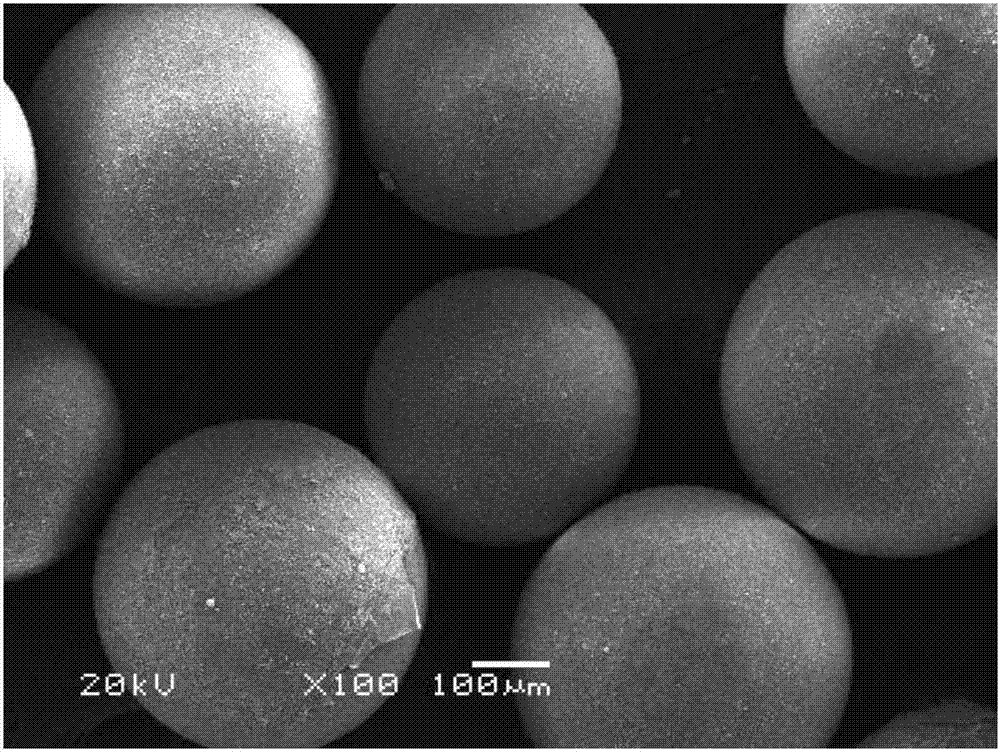

[0028] (1) Preparation of porous biphenyl resin

[0029] Prepare 1 L of an aqueous solution containing 10 g / L of polyvinyl alcohol and 20 g / L of gelatin as the aqueous phase solution of the reaction system for preparing biphenyl porous polymer microspheres by suspension polymerization. Dissolve 120mg of benzoyl peroxide in a mixed solution containing 12mL of 4-vinylbiphenyl, 3mL of divinylbenzene and 18mL of n-heptane, add the oily mixed solution to 60mL of aqueous solution, and the resulting oil-water two-phase separation The mixed system of layers was stirred at room temperature at a mechanical stirring speed of 300rpm for 4h, then the temperature was raised to 80°C, and the polymerization reaction was carried out for 24h. Dry it under vacuum for 12 hours before use.

[0030] Chloromethyl resin preparation

[0031] Slowly add 40mL of thionyl chloride into 40mL of methylal, stir for 1h, mix the resulting solution with 20g of biphenyl resin, soak at 25°C for 2h. Add 6g ZnCl...

Embodiment 2

[0036] (1) Preparation of porous biphenyl resin

[0037] Prepare 1L of aqueous solution containing polyvinyl alcohol (PVA) as 8g / L and gelatin as 14g / L as the aqueous phase solution of the biphenyl porous polymer microsphere reaction system prepared by suspension polymerization. 120mg of benzoyl peroxide (BPO) was dissolved in a mixed solution containing 12mL of 4-vinylbiphenyl, 3mL of divinylbenzene and 20mL of n-heptane, and the oily mixed solution was added to 60mL of aqueous solution to obtain oil-water The two-phase layered mixed system was stirred at room temperature at a mechanical stirring speed of 300rpm for 4h, then the temperature was raised to 80°C, and the polymerization reaction was carried out for 24h. Dry it under vacuum for 12 hours before use.

[0038] Chloromethyl resin preparation

[0039] Slowly add 40mL of thionyl chloride into 40mL of methylal, stir for 1h, mix the resulting solution with 20g of biphenyl resin, soak at 25°C for 2h. Start the stirrer a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap