Gear end face profiling chamfering machining head

A gear end and processing head technology, which is applied in metal processing equipment, gear tooth manufacturing devices, belts/chains/gears, etc. It can solve problems such as difficult adjustments, inability to meet processing requirements, and small adjustment range of chamfering angles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

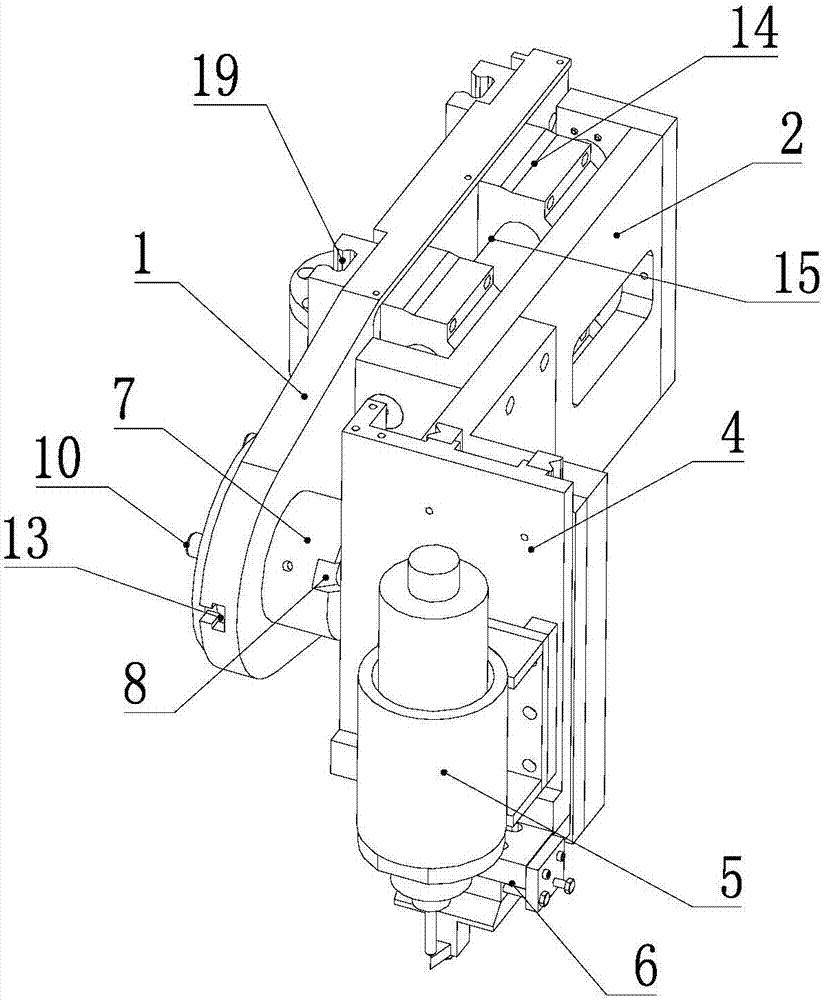

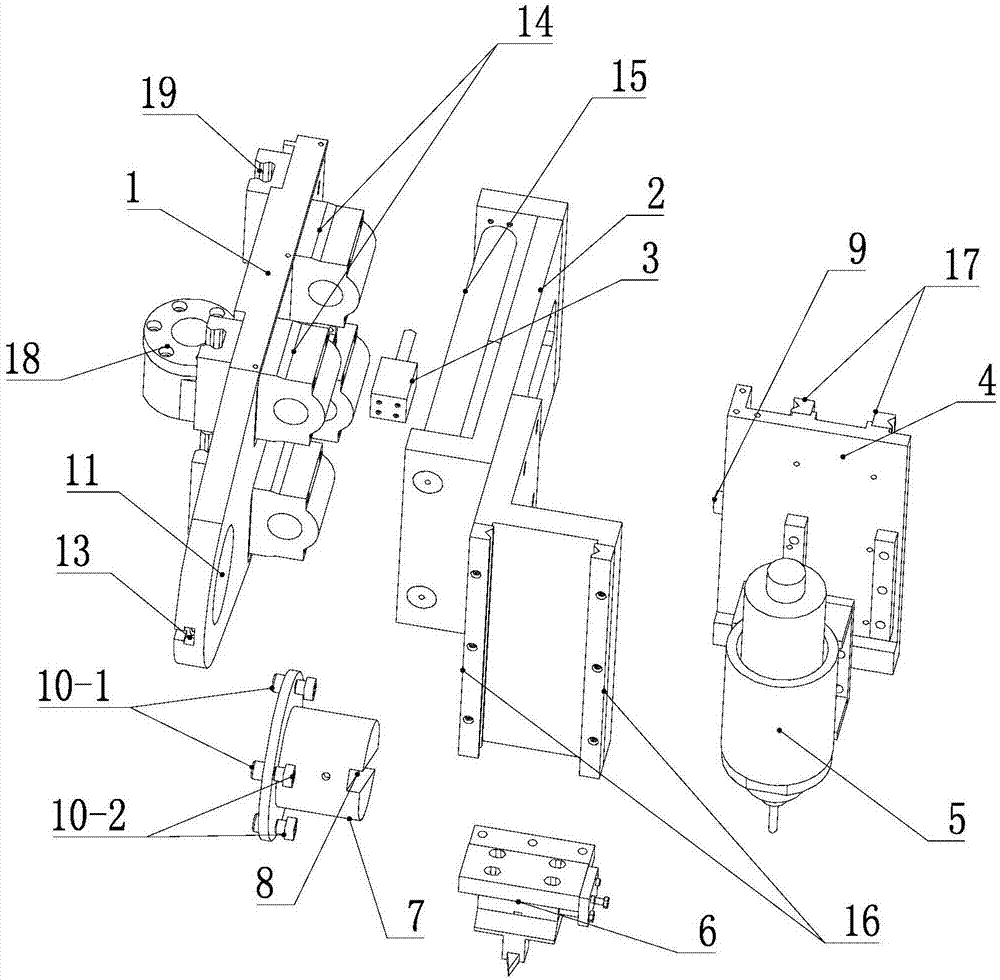

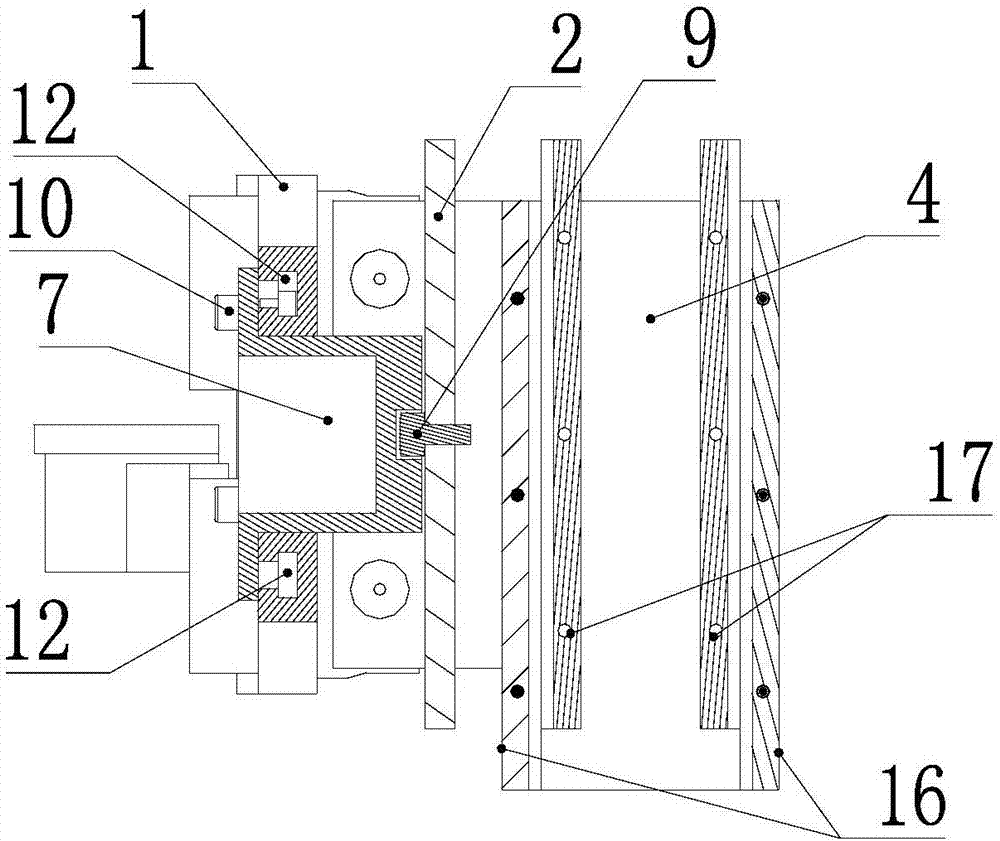

[0021] Such as Figure 1 to Figure 3 The shown gear end profiling and chamfering processing head includes a bracket 1, on which a supporting plate 2 is movable, and the supporting plate 2 moves in the horizontal direction, and the device for making the supporting plate 2 move horizontally is as follows: There is a sliding seat 14, and a sliding column 15 cooperating with the sliding seat 14 is provided on the supporting plate 2. At the same time, a driving device 3 is set on the bracket 1, and the supporting plate 2 is driven by the driving device 3 to move between the guiding sliding column 9 and the sliding seat 14. Coordinated to move along the horizontal direction, the driving device is a hydraulic oil cylinder or an air cylinder. One end of the supporting plate 2 is movably provided with a slide plate 4, the slide plate 4 can move in the vertical direction, a slide rail 16 and a slideway 17 are respectively provided on the support plate 2 and the slide plate 4, and the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com