A mobile chamfering robot attached to a steel plate

A robot and chamfering technology, which is applied in the direction of grinding drive devices, grinding machine parts, machine tools suitable for grinding the edge of workpieces, etc., can solve the problems of not being suitable for large steel plate chamfering, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

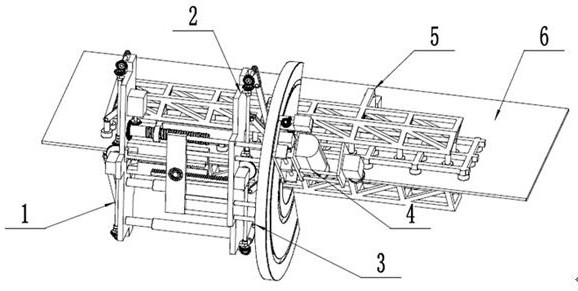

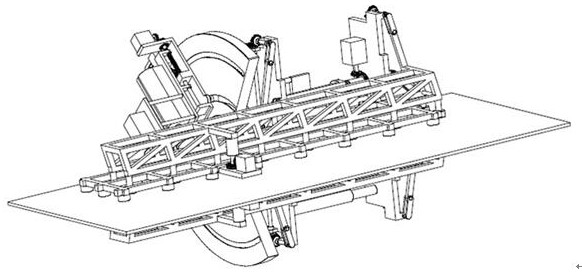

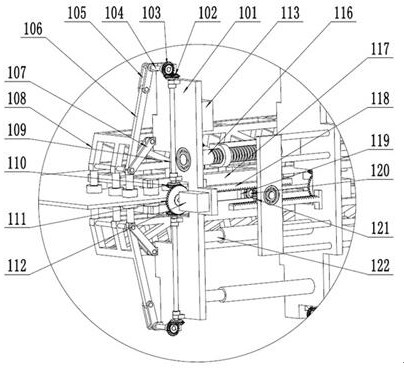

[0020] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6In the mobile chamfering robot attached to the steel plate shown, the second rotating shaft 109 of the leg of the mechanism 1 before walking has two symmetrical rotations installed on the supporting plate 101 of the mechanism before walking, and the third bevel gear 110 of the leg is fixedly installed At one end of the second rotating shaft 109 of the leg, and form a gear fit with the fourth bevel gear 111 of the leg, the fourth bevel gear 111 of the leg is fixedly installed on the rotating shaft of the leg motor 112, and the leg motor 112 is fixedly installed on the walking shaft On the front mechanism support plate 101, the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com