Full-automatic wood board chamfering device

A chamfering device and fully automatic technology, which is applied in the direction of grinding drive device, grinding feed movement, grinding machine, etc., can solve the problems of time-consuming, labor-intensive, difficult operation of hand-held electric planer for workers, and difficulty in controlling accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

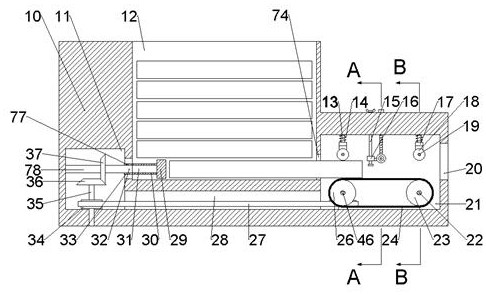

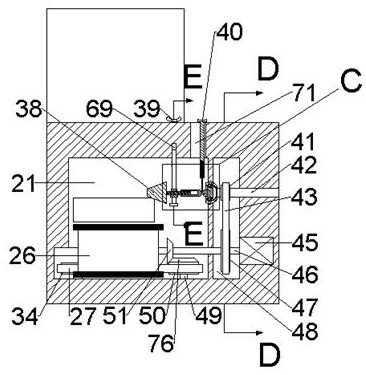

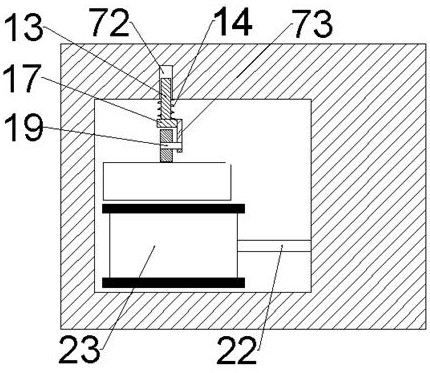

[0017]Combine belowFigure 1-6The present invention will be described in detail, in which, for the convenience of description, the following directions are specified as follows:figure 1 The vertical, horizontal, front and rear directions of the projection relationship are the same.

[0018]An automatic wood chamfering device described in conjunction with Figures 1-6 includes a main box body 10, the main box body 10 is provided with a pushing working cavity 11, the right side of the pushing working cavity 11 is connected with a pusher Block receiving cavity 33, the right side of the pushing block receiving cavity 33 is connected with a plate placing cavity 12, and the lower side of the pushing block receiving cavity 33 is provided with a belt transmission cavity 28 communicating with the pushing working cavity 11. The right side of the placing cavity 12 is connected with a steering limit cavity 74, the right side of the steering limit cavity 74 is connected with a working cavity 21, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com