Demolding mechanism for internally-threaded piece with reverse buckles

A technology of demoulding mechanism and internal thread, which is applied in the field of demoulding structure, can solve the problems of thread undercut and complex structure of damaged products, and achieve the effect of protecting thread and undercut, simple device structure and good market prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be further described in detail below in conjunction with specific embodiments.

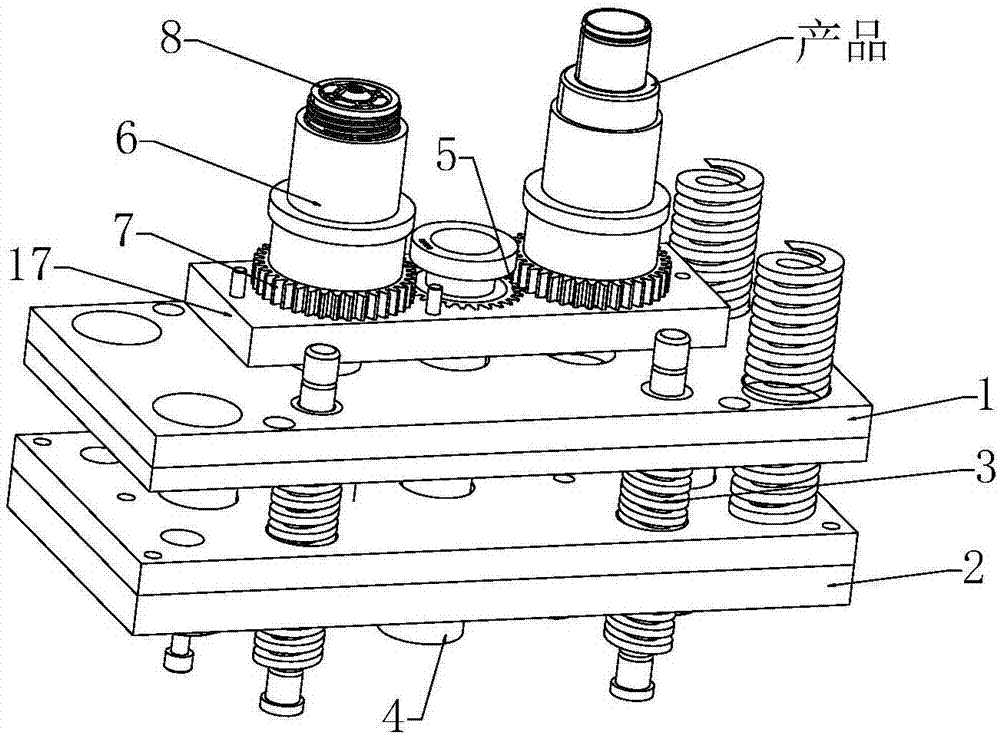

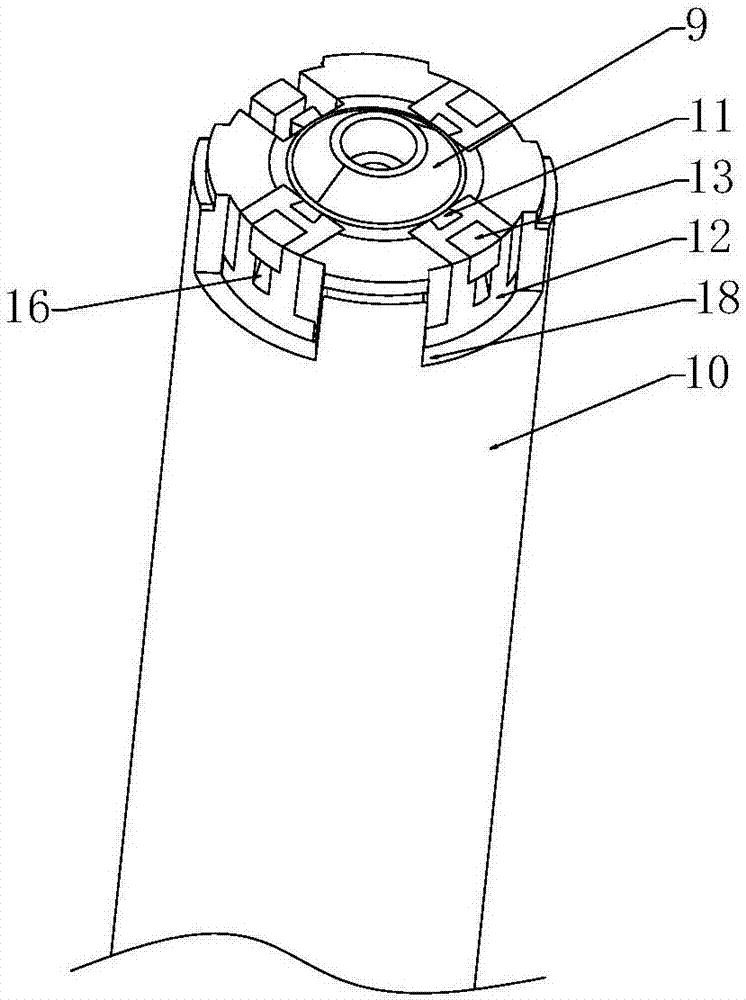

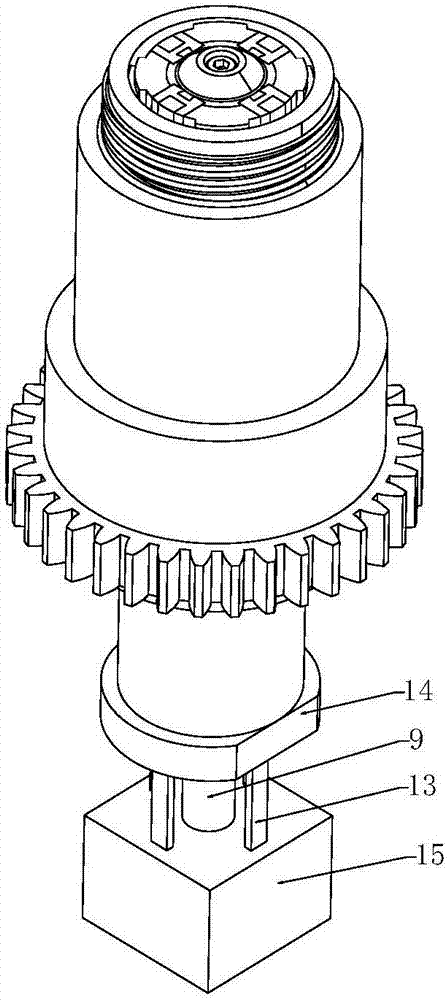

[0022] See Figure 1-6 , A demoulding mechanism for internally threaded parts with undercuts, including spring plate 1, top plate 2, main shaft 4, threaded shaft 6, inner rod 8 and mounting plate 17; said mounting plate 17, spring plate 1 and The top plate 2 is arranged directly opposite from top to bottom and there is a gap between the two. The bottom four corners of the elastic plate 1 are provided with top extension springs 3; the main shaft 4 passes through the top plate 2 and the elastic plate 1 from the bottom to the mounting plate 17 The top of the drive gear 5 is connected to the main shaft 4, and the main shaft 4 is provided with a driving mechanism for driving it to rotate; the threaded shaft 6 has two symmetrically arranged on both sides of the drive gear 5, the threaded shaft 6 is rotated to connect the mounting plate 17, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com