Quick connection structure for widening bridge floor system of bridge through UHPC material

A technology of fast connection and bridge deck system, which is applied in the direction of bridges, bridge parts, bridge materials, etc., can solve problems such as cracking in the rigid connection area of the bridge deck, uneven settlement, and affecting the durability of the joint structure, so as to reduce on-site work quantity, avoidance of welding work, effect of quick connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

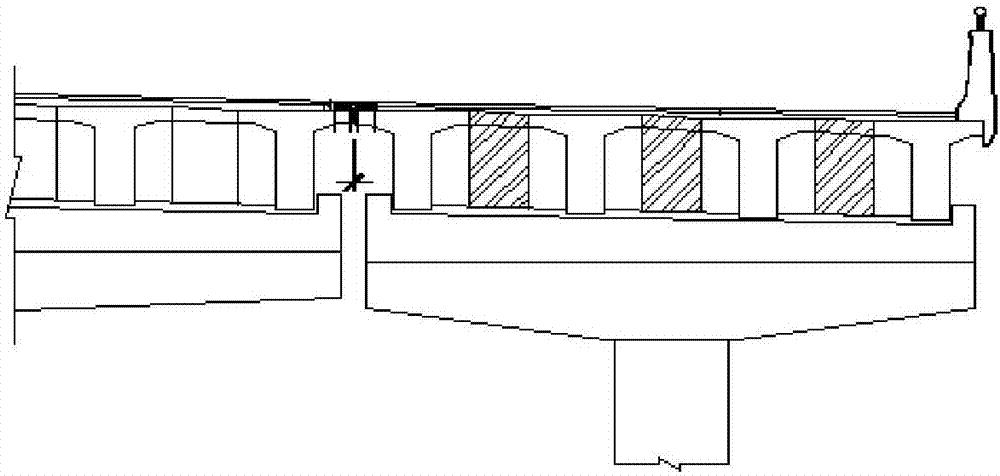

[0020] refer to Figure 4 As shown in the figure, a quick-connection structure of a widened bridge deck system using UHPC materials, including the existing bridge 1 and the newly built bridge 5, the upper end surface on the right side of the existing bridge 1 and the upper end surface on the left side of the newly built bridge 5 The L place is evenly inserted with a shearing steel bar 2, and a layer of UHPC concrete layer 4 is laid across the gap above the shearing steel bar 2, and a layer of asphalt concrete pavement layer 3 is laid on the upper end of the UHPC concrete layer 4, wherein, the length of L is 4000mm. A layer of conventional reinforced concrete pavement 6 is laid on the left upper end surface of the existing bridge 1 and the right upper end surface of the newly-built bridge 5, and a layer of asphalt concrete pavement 3 is laid on the upper end surface of the reinforced concrete pavement 6. .

[0021] In this embodiment, the side surface of the existing bridge s...

Embodiment 2

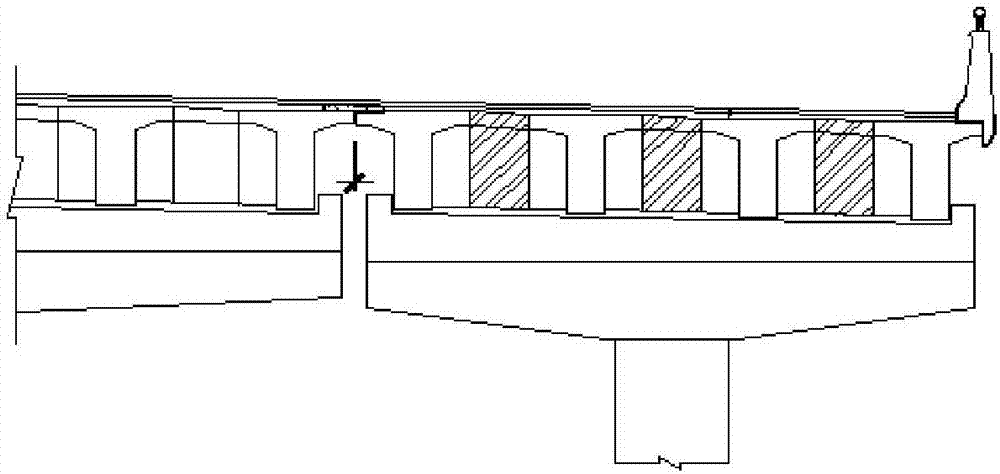

[0023] refer to Figure 5 As shown, the difference from Example 1 is that there is a wet joint section A between the existing bridge 1 and the newly built bridge 5 in the present situation, and the wet joint section A of the rigid connection between the old and new bridge decks adopts UHPC concrete 8 pouring. The distance between the new and old bridge deck rigidly connecting the wet joint section A is 200-300mm.

[0024] In this embodiment, the side girders of the existing bridge superstructure are drilled to expose the horizontal steel bars in the bridge deck, and vertical shear steel bars 2 are planted within a certain range on the top of the widened side beams. The superstructure of the newly built bridge 5 connects with the existing bridge 1 and the lateral bridge deck is reserved to reserve horizontally protruding steel bars to ensure that the staggered length of the horizontal steel bars excavated from the existing existing bridge 1 in the cross bridge direction after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com