Prefabricated foundation and assembling method thereof

A prefabricated assembly and basic technology, applied in the direction of infrastructure engineering, construction, etc., can solve the problems of inability to realize standardized operations and large impact, and achieve the effects of improving work efficiency, reducing wet operations, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further explained below in conjunction with specific embodiments, but the present invention is not limited thereto.

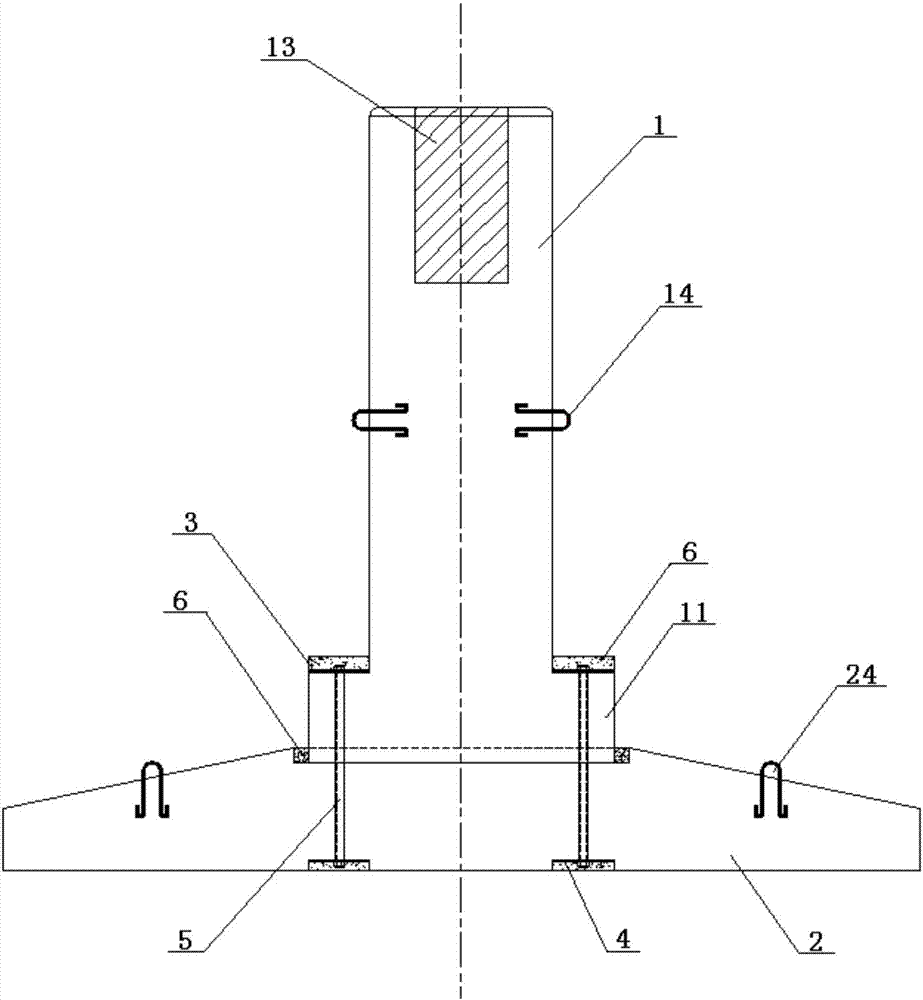

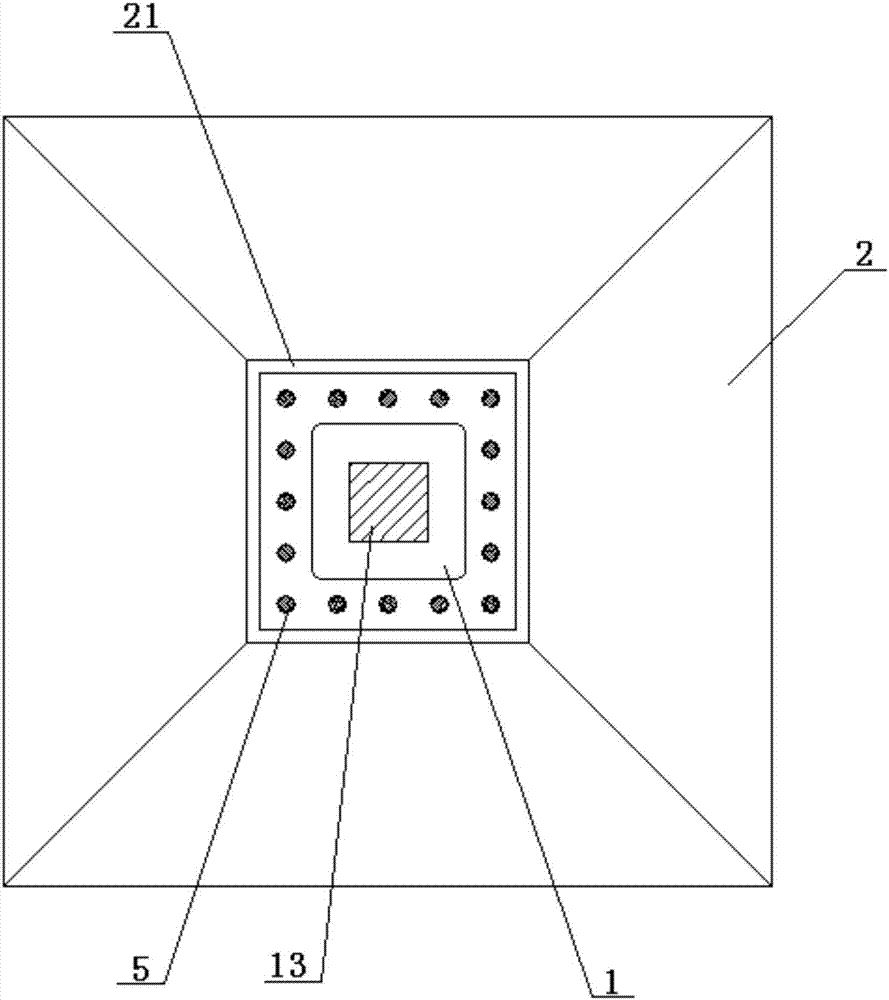

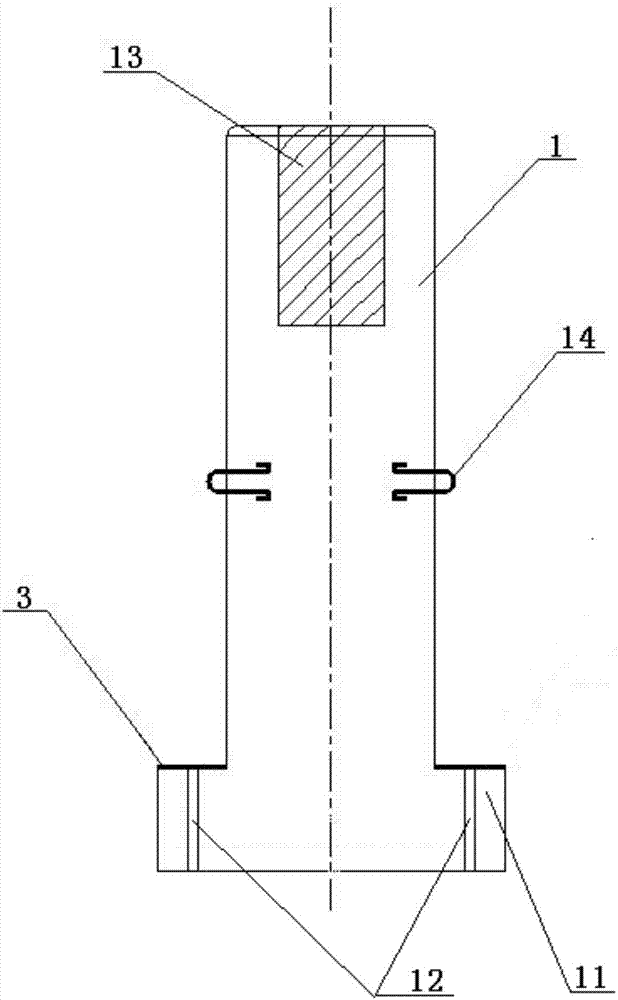

[0027] Such as figure 1 To such as Figure 4 As shown, the present invention provides a prefabricated assembled foundation, comprising: a foundation short column 1 and a foundation chassis 2 of a reinforced concrete structure, wherein the lower part of the foundation short column 1 is fixedly connected with a short column platform 11 along its circumference, The two preferably have an integral structure, the top of the short column pick platform 11 is fixed with a pressure backing plate I3, the steel casing I12 is arranged at intervals along its circumferential direction in the short column pick platform 11, and the upper part of the foundation chassis 2 is provided with The mounting groove 21 matched with the table 11 has a groove 22 corresponding to the pressure backing plate I3 at the bottom, a pressure backing plate II4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com