A preparation method and product of graphite microflake/natural rubber latex composite material

A technology of graphite microflakes and natural rubber latex, which is applied in the field of preparation of graphite microflakes/natural latex composite materials, can solve the problems of high price, limited improvement of mechanical strength and thermal conductivity/conductivity, and scarce output, so as to improve mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

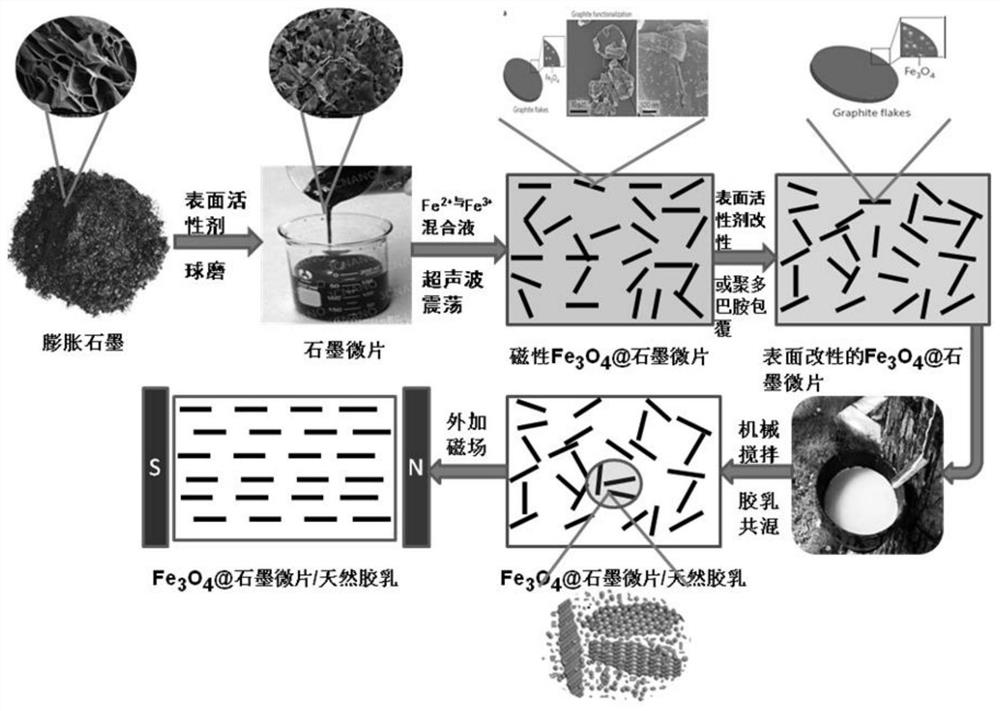

[0035] (1) Preparation of nanographite microflakes:

[0036] Add 100g of expanded graphite and 0.1g of sodium dodecylbenzenesulfonate into a ball milling tank, add 2500mL of distilled water and 800g of agate ball milling beads, set the speed of the ball mill at 300r / min, and mill for 24 hours to prepare nano-graphite microflakes.

[0037] It is determined that the diameter of the prepared nano-graphite is 2000-5000nm, the thickness is 10-20nm, and the diameter-thickness ratio is (100-500):1.

[0038] (2) Fe 3 o 4 Preparation of @graphite microchips:

[0039] The nano graphite flakes prepared by step (1) are uniformly dispersed in 1000mL water to make nano graphite flake suspension, wherein the content of nano graphite flakes is 0.0336g / mL; the preparation contains 0.2molFeCl 3 and 0.1molFeCl 2 100mL of the mixed solution; inject the uniformly dispersed nano-graphite microplate suspension into FeCl 3 and FeCl 2 In the mixed solution, under the power of 1000W, ultrasonically...

Embodiment 2

[0045] (1) Preparation of nanographite microflakes:

[0046] Add 100g of expanded graphite and 0.5g of sodium dodecylbenzenesulfonate into a ball milling tank, add 2500mL of distilled water and 800g of agate ball milling beads, set the speed of the ball mill to 400r / min, and mill for 26 hours to prepare nanographite microflakes.

[0047] It is determined that the diameter of the prepared nano-graphite is 2000-5000nm, the thickness is 10-20nm, and the diameter-thickness ratio is (100-500):1.

[0048] (2) Fe 3 o 4 Preparation of @graphite microchips:

[0049] The nano graphite flakes prepared by step (1) are uniformly dispersed in 1000mL water to make nano graphite flake suspension, wherein the content of nano graphite flakes is 0.0168g / mL; the preparation contains 0.2molFeCl 3 and 0.1molFeCl 2 100mL of the mixed solution; inject the uniformly dispersed nano-graphite microplate suspension into FeCl 3 and FeCl 2 In the mixed solution, ultrasonically oscillate and mechanical...

Embodiment 3

[0055] (1) Preparation of nanographite microflakes:

[0056] Add 100g of expanded graphite and 1g of phosphoric acid ester into a ball mill jar, add 2500mL of distilled water and 800g of agate ball milling beads, set the speed of the ball mill at 500r / min, and mill for 36h to prepare nano-graphite microflakes.

[0057] It is determined that the diameter of the prepared nano-graphite is 2000-5000nm, the thickness is 10-20nm, and the diameter-thickness ratio is (100-500):1.

[0058] (2) Fe 3 o 4 Preparation of @graphite microchips:

[0059] The nano graphite flakes prepared by step (1) are uniformly dispersed in 1000mL water to make nano graphite flake suspension, wherein the content of nano graphite flakes is 0.0252g / mL; the preparation contains 0.2molFeCl 3 and 0.1molFeCl 2 100mL of the mixed solution; inject the uniformly dispersed nano-graphite microplate suspension into FeCl 3 and FeCl 2 In the mixed solution, ultrasonically oscillate and mechanically stir under the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com