Reversed-V-shaped deflector rod

A herringbone, main pole technology, applied in building types, buildings, towers, etc., can solve the problems of not being able to lift safely and steadily, not increasing the grounding area, increasing the labor intensity, etc., to achieve compact structure and reduce labor. Labor intensity, lifting safety and smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

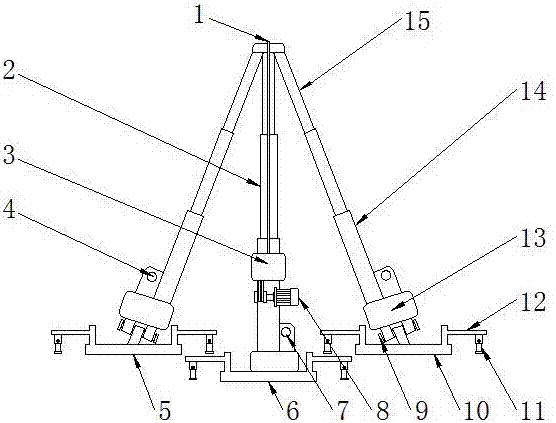

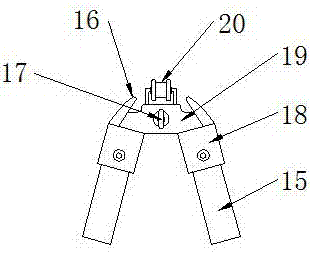

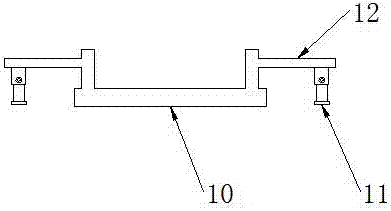

[0018] Example: such as Figure 1-3 As shown, the present invention provides a technical solution, a herringbone lever, including a steel wire rope 1, a main rod 2, a transmission 3, a first hydraulic jack 4, a first auxiliary fixing frame 5, a main rod auxiliary fixing frame 6, Main rod hydraulic jack 7, servo motor 8, rotating shaft 9, second auxiliary fixing frame 10, telescopic leg 11, connecting rod 12, second hydraulic jack 13, sealed outer tube 14, telescopic rod 15, protective cover 16, hook 17, Connect the sleeve 18, the connecting seat 19 and the fixed pulley 20, the bottom end of the first hydraulic jack 4 is fixed with the first auxiliary fixing frame 5, the front side of the first auxiliary fixing frame 5 is provided with the main rod auxiliary fixing frame 6, the main rod The top of the auxiliary holder 6 is provided with a main rod hydraulic jack 7, and the rear side of the main rod auxiliary holder 6 is provided with a second auxiliary holder 10, and the top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com