Two-stage series-connection high-pressure fuel pump

A high-pressure fuel and secondary pump technology, applied in the field of oil pumps, can solve the problems of heavy weight, large space size, and inability to meet new engines, and achieve the effect of light weight and small space size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

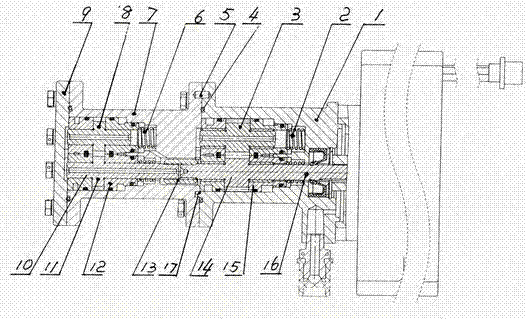

[0007] Such as figure 1 As shown, the technical solution of the present invention is that the flange at the left end of the main pump casing 1 and the flange surface at the right end of the secondary pump casing 7 are respectively provided with an axial hole that is slidingly matched with the positioning pin 5 and a sealing ring. 4 Matching annular grooves, the left end face of the main pump flange is provided with a positioning block 17 matching the groove on the right end face of the secondary pump flange, and screw holes are evenly distributed on the outside of the above two flanges, wherein The function of the positioning pin is to ensure the concentric requirements of the main pump and the secondary pump. The drive shaft 16 of the main pump is driven by a motor. The left end of the main pump shaft is provided with an external spline that engages with the internal spline of the coupling sleeve 13. The external splines that are engaged with the keys are used to drive the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com