An automatic reset smoke exhaust fire damper

An automatic reset and fire damper technology, applied in the direction of balance valves, valve devices, valve details, etc., can solve problems such as increased cost of use, drop, complicated installation process, etc., and achieve simplified structure, increased action speed, and accurate action temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

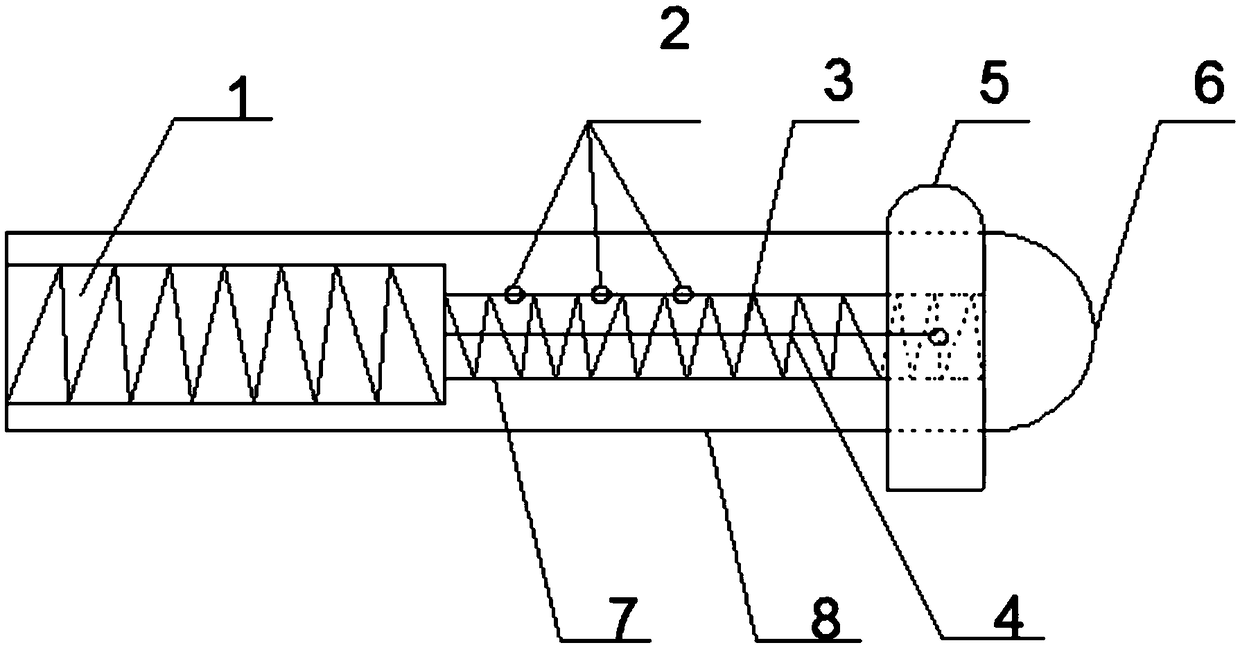

[0017] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

[0018] The automatic reset smoke exhaust fire damper provided by the present invention, the memory alloy spring of the automatic reset smoke exhaust fire damper is made of nickel-titanium-based alloy;

[0019] The nickel-titanium-based alloy components are composed of 30% to 30.2% of Ti with a purity of 99.99%, 48% to 50% of Ni with a purity of 99.99%, 20% of Hf with a purity of 99.95%, and 0.03% to 0.1% of Re in proportion by mass ; The nickel-titanium-based alloy is prepared by arc induction melting under the protection of argon.

[0020] The structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0021] Such as figure 1 As shown, in the automatic reset smoke exhaust fire damper provided by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com