A standard sample for calibration measurement of fluorescence instruments and preparation method thereof

A technology for calibration measurement and standard sample, applied in the field of fluorescence instrument calibration measurement, can solve the problems of inability to precisely control the consistency of the thickness of the fluorescent material film, inability to produce small-scale graphics with complex patterns, and inability to accurately control the fluorescence intensity, etc. The effect of optimizing the calibration measurement process, improving usability, increasing complexity and sophistication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

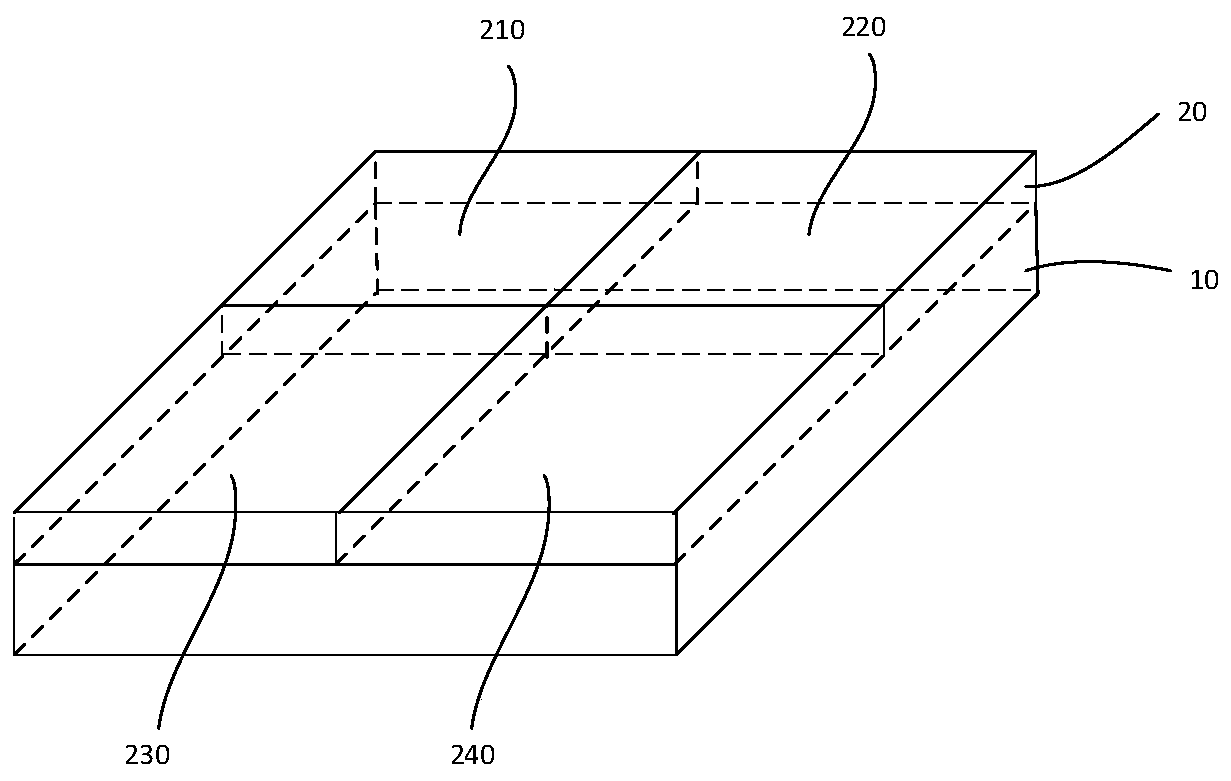

[0040] Such as figure 1 As shown, a standard sample used for calibration and measurement of a fluorescent instrument includes a substrate 10 and a fluorescent film 20. The fluorescent film 20 is disposed on the substrate 10 and includes a plurality of fluorescent intensity regions with different fluorescent intensities, and each of the plurality of fluorescent intensity regions has a specific fluorescent dye filling duty ratio.

[0041] It should be noted that, in the present invention, that each of the plurality of fluorescence intensity regions has a specific fluorescent dye filling duty ratio means that different fluorescent intensity regions have different fluorescent dye filling duty ratios.

[0042] In this embodiment, the substrate 10 is a glass substrate, and the fluorescent film 20 includes, for example, four fluorescence intensity regions, which are a first fluorescence intensity region 210, a second fluorescence intensity region 220, a third fluorescence intensity region ...

Embodiment 2

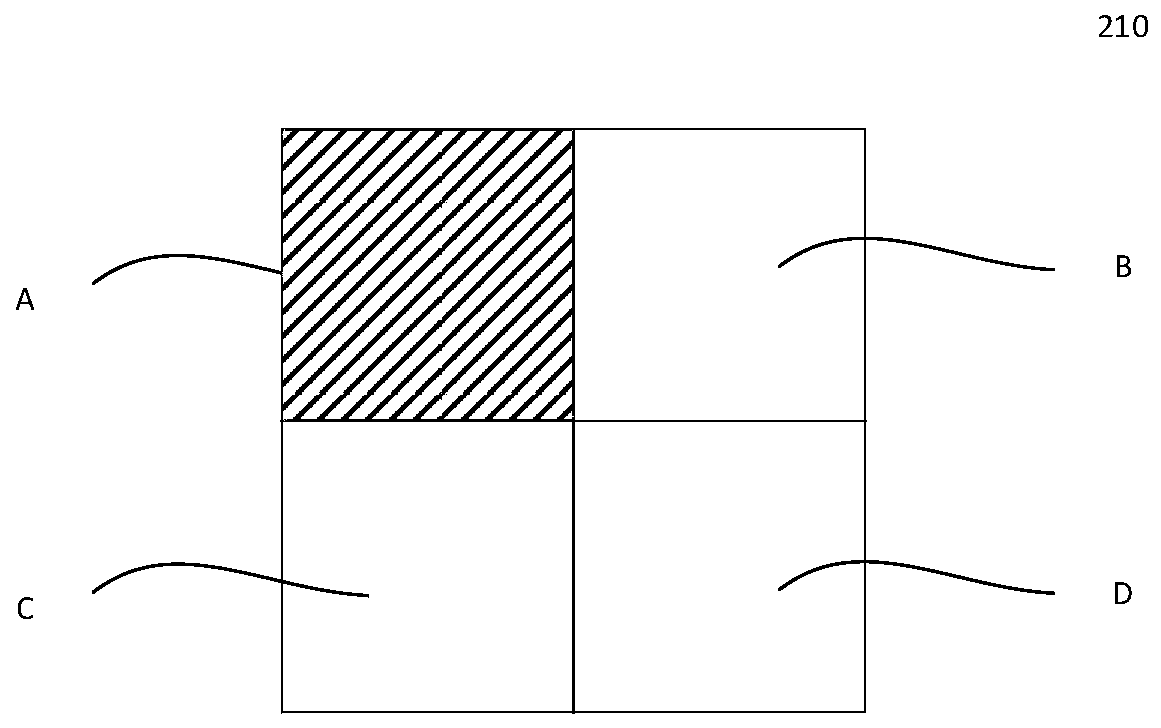

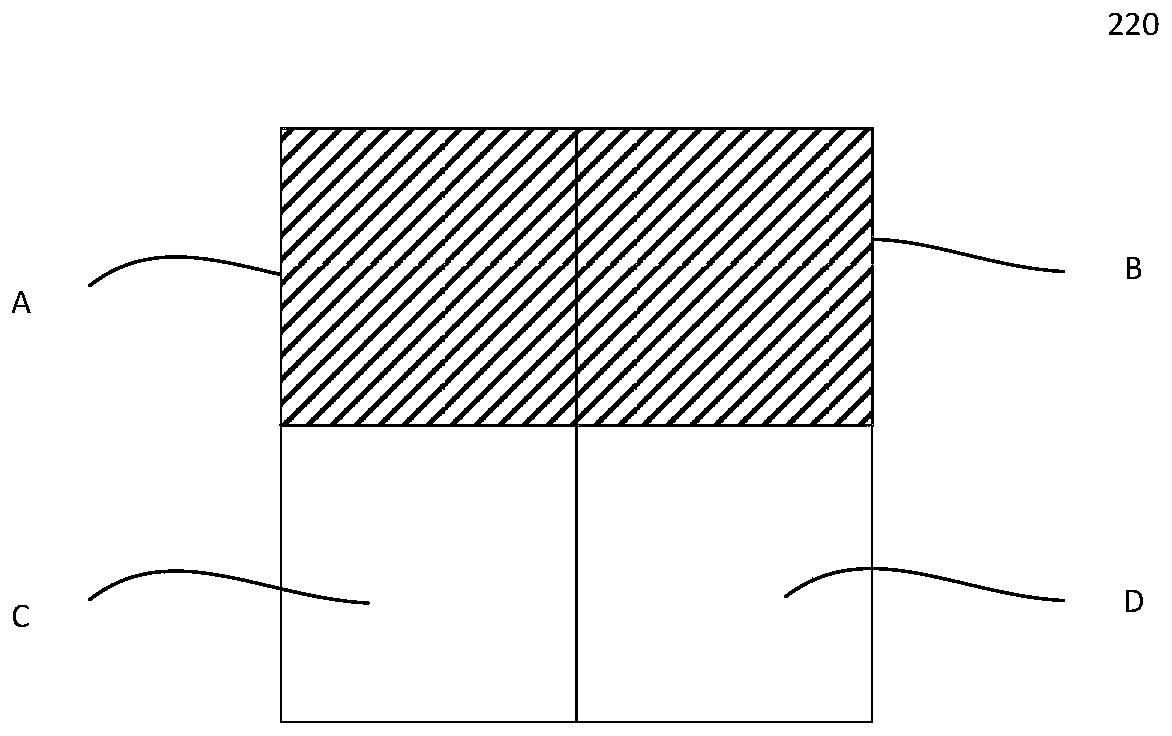

[0045] A standard sample used for calibration and measurement of a fluorescent instrument includes a substrate 10 and a fluorescent film 20. The fluorescent film 20 is disposed on the substrate 10 and includes a plurality of fluorescent intensity regions with different fluorescent intensities, the fluorescent intensity region includes a plurality of repeating units corresponding to pixels, and the repeating units in the same fluorescent intensity region have the same fluorescent dye filling Duty cycle.

[0046] Such as Figure 2-Figure 5 As shown, in this embodiment, for example, the fluorescent film 20 includes four fluorescent intensity regions, namely a first fluorescent intensity region 210, a second fluorescent intensity region 220, a third fluorescent intensity region 230, and a fourth fluorescent intensity region 240. For example, the first fluorescence intensity region 210 includes m first repeating units, the second fluorescence intensity region 220 includes n second re...

Embodiment 3

[0051] On the basis of the above-mentioned embodiment 1 and embodiment 2, in order to improve the firmness of the inorganic fluorescent material on the substrate, a protective layer can be coated on the surface of the substrate on which the fluorescent film is formed. The commonly used protective layer is polymethylsiloxane (PDMS ) Film or polyvinyl alcohol (PVA) film and other transparent low-fluorescence background film, the thickness of the film should be less than 50 microns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com