Waterproof sound cavity

A sound cavity and waterproof film technology, which is applied in the field of audio equipment, can solve the problem that waterproof is difficult to meet the requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

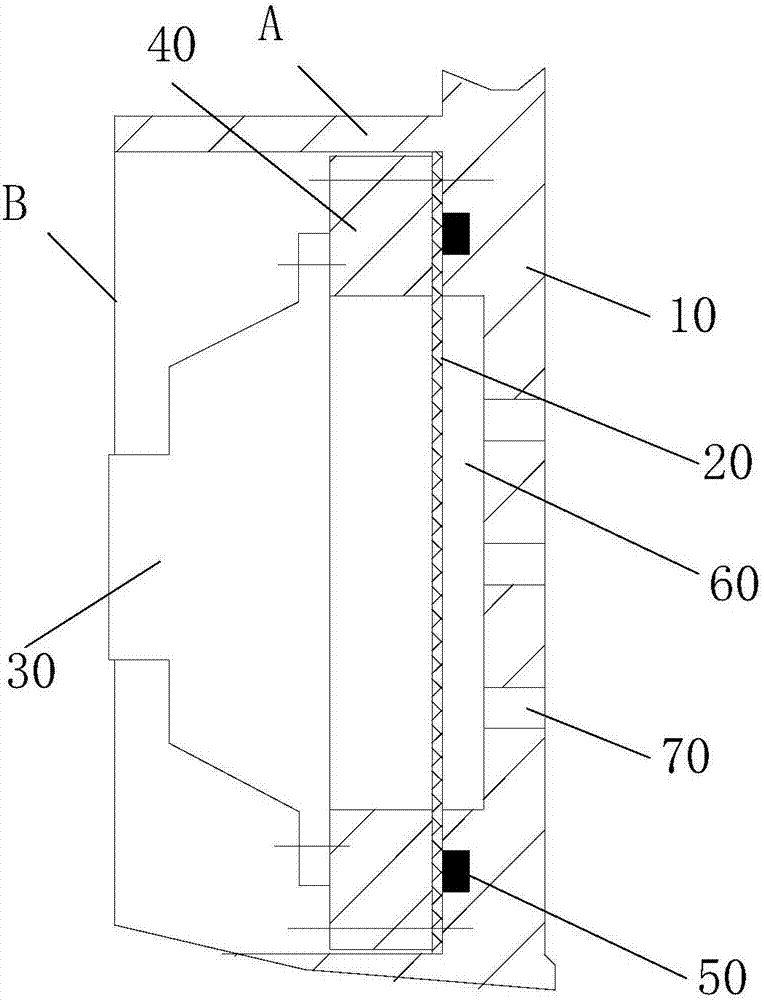

[0020] figure 1 It is a schematic structural diagram of a waterproof sound cavity provided by an embodiment of the present invention, see figure 1 , The waterproof sound cavity includes a panel 10, a waterproof membrane 20, a speaker 30, a pressure plate 40 and a sealing ring 50. The middle of the panel 10 is provided with a first groove 60. The part of the panel 10 where the first groove 60 is provided is provided with a number of small holes 70. The small holes 70 are through holes, that is, at the bottom of the first groove 60 A number of small holes 70. The panel 10 is also provided with an annular second groove surrounding the first groove 60, a sealing ring 50 is arranged in the second groove, and the waterproof membrane 20 is arrange...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap