Vacuum fluorescent float

A fluorescent and float technology, applied in fishing accessories, fishing, applications, etc., can solve problems such as poor visibility, decreased buoyancy of floats, slow processing speed, etc., to avoid internal water seepage, excellent sealing, production and Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

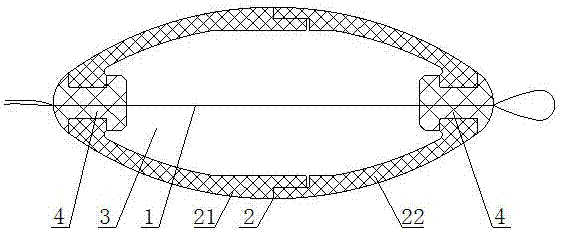

[0013] like figure 1 As shown, the vacuum fluorescent float includes the fluorescent float body 2 and the lead wire 1. The interior of the fluorescent float body 2 is hollow to form a vacuum chamber 3. The vacuum chamber 3 is filled with hydrogen gas. Compared with the traditional float of the same volume, the buoyancy is greatly increased. The two ends of the fluorescent float body 2 are closed by I-shaped end caps 4, which can effectively avoid internal water seepage. The buoyancy is large and stable, and the draft is fast. There is no need to constantly adjust the float weight, and the sensitivity is high. The visibility is also better. It is beneficial to reduce the amount of the float when used or reduce the volume during production. The lead wire 1 is combined into two pieces and passed through two I-shaped end caps 4 in turn. The I-shaped end cap 4 is made of elastic rubber and plastic material, fluorescent The float body 2 is made of hard plastic.

[0014] In the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com