Punching scrap outputting device

A technology of exporting device and scrap, applied in the field of stamping equipment, can solve the problem that stamping scrap cannot be exported in time, and achieve the effect of shortening the sliding stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

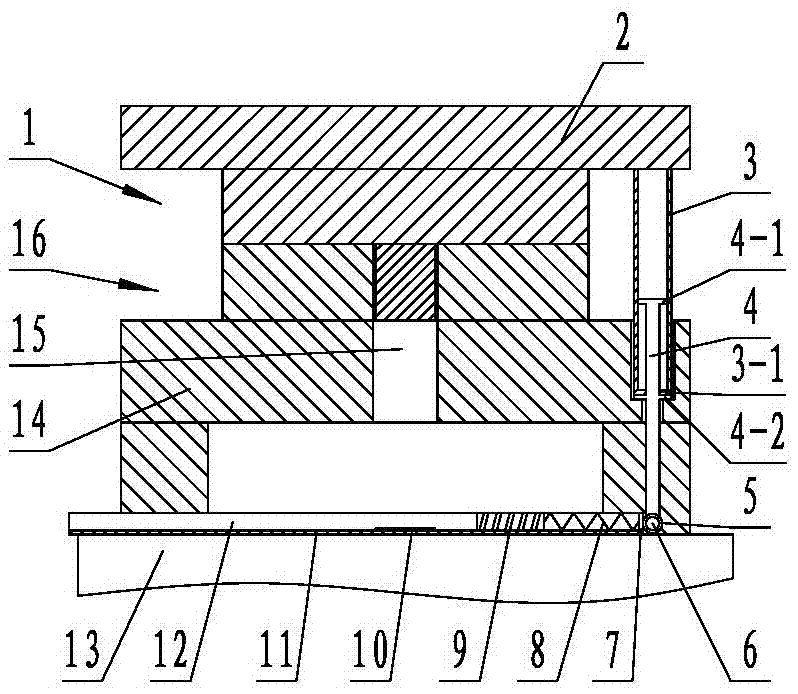

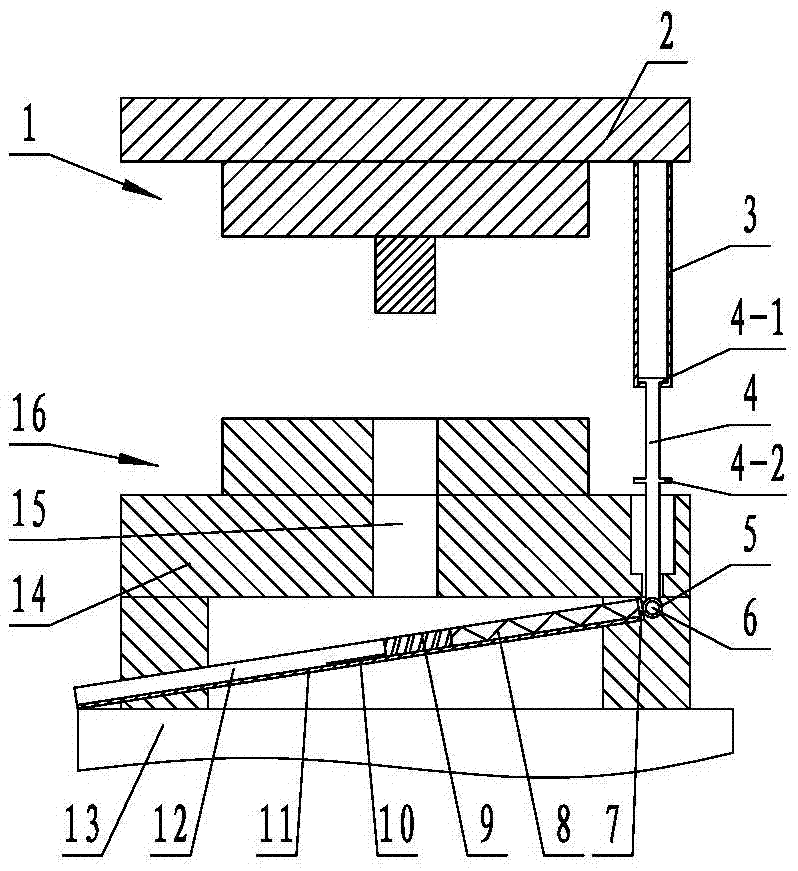

[0014] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

[0015] figure 1 and figure 2 The shown punching waste exporting device mainly includes a material receiving plate 11, a push block 9, a spring 8, a positioning pin sleeve 5, a pin shaft 6, a lifting rod 7 and a guide sleeve 3, and the material receiving plate 11 is arranged on the workbench 13 and Located below the lower die base 14, in order to facilitate the smooth export of punched waste 10, the length direction of the material receiving plate 11 is set along the width direction of the worktable 13, and one end of it stretches out from the edge of the workbench 13 as a discharge end, and the other end is provided with an end plate 7 , a positioning pin sleeve 5 is fixed on the outside of the end plate 7, and a pin shaft 6 is inserted in the positioning pin sleeve 5. The pin shaft 6 is hinged with a vertically arranged lifting rod 4, and the lifting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com