Turbine molecular pump bearing block

A technology for turbomolecular pumps and bearing housings, which is applied in the field of bearing housings of turbomolecular pumps and rotors of small turbomolecular pumps. It can solve problems such as vibration reduction of rolling bearings, reduce vibration impact, prolong service life, and reduce vibration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

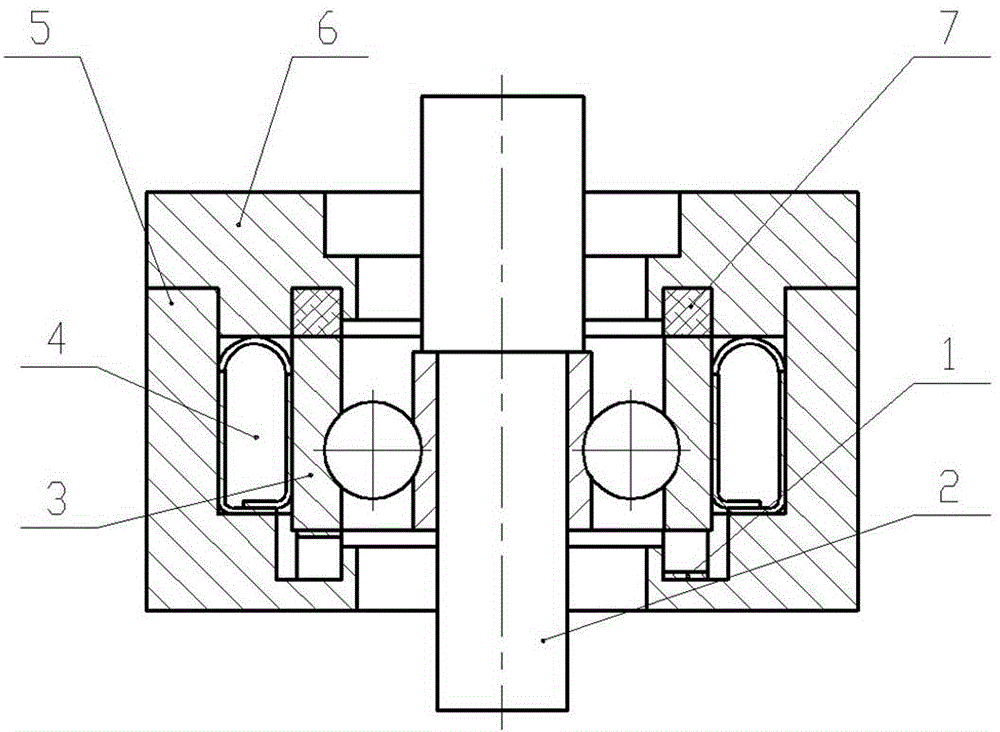

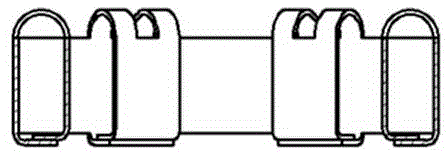

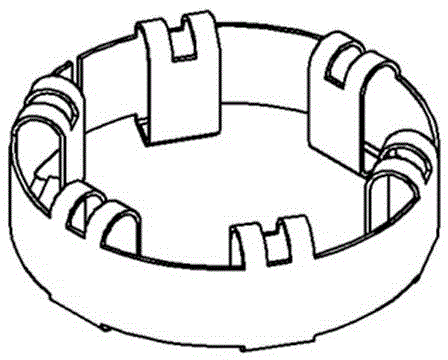

[0019] figure 1 It is a schematic cross-sectional view of the turbomolecular pump bearing seat of the present invention, Fig. 2(a) is a cross-sectional view of the friction disc radial spring in the present invention, and Fig. 2(b) is a perspective view of the friction disc radial spring in the present invention. exist figure 1 , in Fig. 2, the turbomolecular pump bearing housing of the present invention includes wave spring 1, rotor shaft 2, rolling ball bearing 3, friction plate type radial spring 4, bearing housing 5, bearing end cover 6, damping rubber ring 7. The connection relationship is that the lower end surface of the bearing end cover 6 and the inner bottom surface of the bearing seat 5 are provided with corresponding grooves. Friction disc type radial spring 4 is housed in the inner hole of the bearing seat 5, which is used for vibration reduction and heat conduction. The rolling ball bearing 3 is placed in the inner hole of the friction type radial spring 4 . T...

Embodiment 2

[0026] The structure of this embodiment is the same as that of Embodiment 1, except that the material used for the friction disc type radial spring is spring steel. The friction plate radial spring has twelve friction plates evenly distributed along the inner circumference

[0027] The shape of the friction plate radial spring is a fractured ring structure, and there are friction plates evenly distributed along the inner circumference. The number of friction plates is set to 6~12. The cloth friction plate can increase the radial friction damping of the spring, reduce the radial vibration of the bearing and export the heat generated by the bearing. One of beryllium bronze and spring steel is used, which has a large thermal conductivity and can timely export the heat generated by the rolling bearing; the structure of uniformly distributed friction plates is beneficial to convert the vibration energy dissipation into heat export, reducing Vibration and shock of bearings.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com