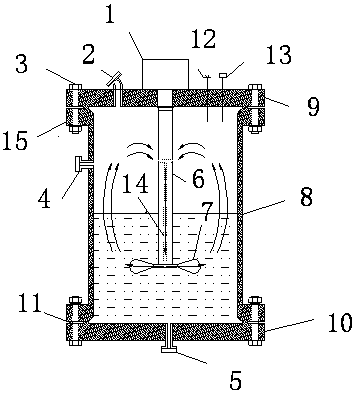

Natural gas hydrate synthesis reaction kettle

A synthetic reaction and hydrate technology, applied in chemical methods for reacting liquid and gaseous media, chemical/physical/physicochemical fixed reactors, gas fuels, etc., can solve problems such as the difficulty of uniform mixing, and achieve Avoid the effect of pore clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Using the hydrate synthesis reaction kettle provided by the present invention, combined with the supporting pressurization system, data acquisition system, feeding system, etc. to synthesize artificial natural gas hydrate, the design pressure of the reaction kettle is 20MPa, and the design temperature is -15°C~40 ℃, the size of the kettle is Φ950mm×1200mm, the total volume of the cavity is 850L, the diameter of the water injection hole is 25mm, and the diameter of the stirring rod is 50mm.

[0030] Using the reactor to synthesize artificial natural gas hydrate, the process is as follows:

[0031] First, add appropriate sand into the reactor, and buckle the upper flat cover of the reactor, then pour in an appropriate amount of water, turn on the stirring rod, cool the reactor, and then add air to the reactor until the required pressure. Since the stirring rod is turned on during the gas filling process, part of the gas passes through the stirring rod and is ejected in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com