Vertical disc type tool changer

A disc cutter and vertical technology, which is applied in the field of CNC machine tool manufacturing, can solve the problems of excessively worn clamping jaws, affecting the high precision of high-speed machining centers, and large bearing capacity of the tool changing manipulator, so as to reduce the possibility of tool drop, Easy to dress and maintain, good swing characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

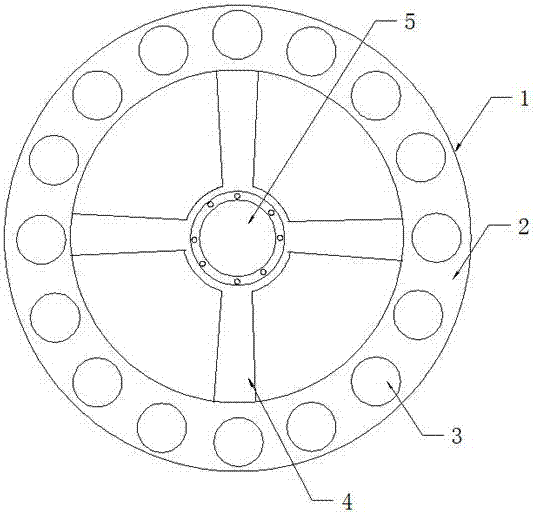

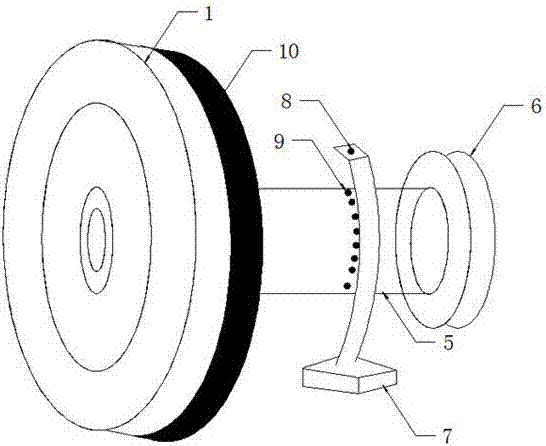

[0018] Such as Figure 1-2 As shown, a vertical disc tool magazine includes a revolving body 1 and a tool holder unit distributed on the surface of the revolving body 1. The revolving body 1 includes an annular tool holder 2 and a rotating shaft 5 located in the middle of the annular tool holder 2. The rotating shaft 5 is provided with a number of induction lamps A9, a counter 7 is provided on the outside of the rotary shaft 5, and an induction lamp B8 is provided on the counter 7. The ring tool holder 2 and the rotary shaft 5 are connected by several support ribs 4, and the rotary shaft 5 passes through the reducer. 6. Connected to the servo motor, the ring tool holder 2 is evenly distributed with several through holes 3 in the axial direction, the tool holder units are respectively arranged in the through holes 3, and the back of the ring tool holder 2 is provided for blocking the through holes 3 to prevent the tool from falling off Active stopper 10.

[0019] Further, the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap