Anti-blocking device of spiral squeezer

A screw press, anti-clogging technology, applied to presses, manufacturing tools, etc., can solve problems such as blockage of screw presses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

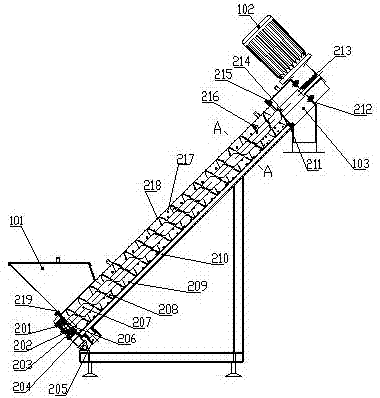

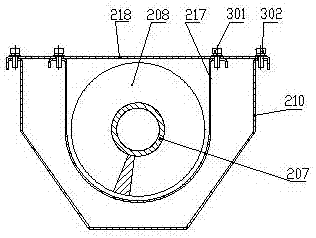

[0014] Figure 4 It is an axonometric view of the screw press anti-clogging device of the present invention, which is mainly composed of a rotating shaft welded, a U-shaped perforated plate 217, and a cover plate 218. For the convenience of observation and illustration, the cover plate 218 is hidden in the figure. The U-shaped perforated plate 217 is fixedly connected with the cover plate 218 by bolts 301 to form a U-shaped space. The rotating shaft is welded and installed in the U-shaped space and coincides with the half-circle axis of the U-shaped space. The deflector 210 is connected to the cover plate 218 by bolts 302 Fixed connection forms a closed space to prevent the leakage of odor in the closed space (see image 3 ).

[0015] The rotary shaft welding of the present invention is based on the existing rotary shaft welding structure (the lower bearing shaft 206, the rotating shaft 207, the forward spiral blade 208, the reverse spiral blade 216, and the upper bearing sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com