Vacuum Heat Sealing Machine

A heat sealing and sealing machine technology, applied in packaging sealing/fastening, transport packaging, packaging, etc., can solve the problems of air not reaching vacuum, low sealing efficiency, and cumbersome manual operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

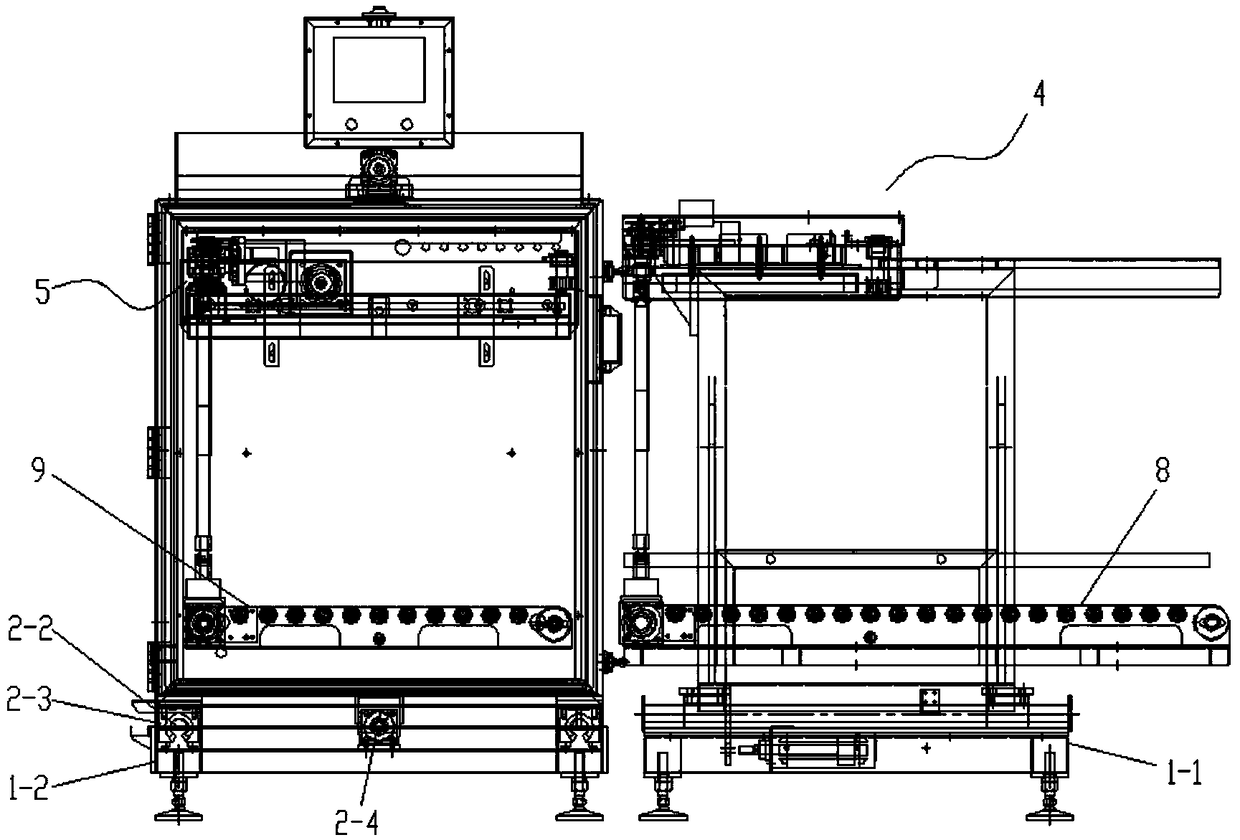

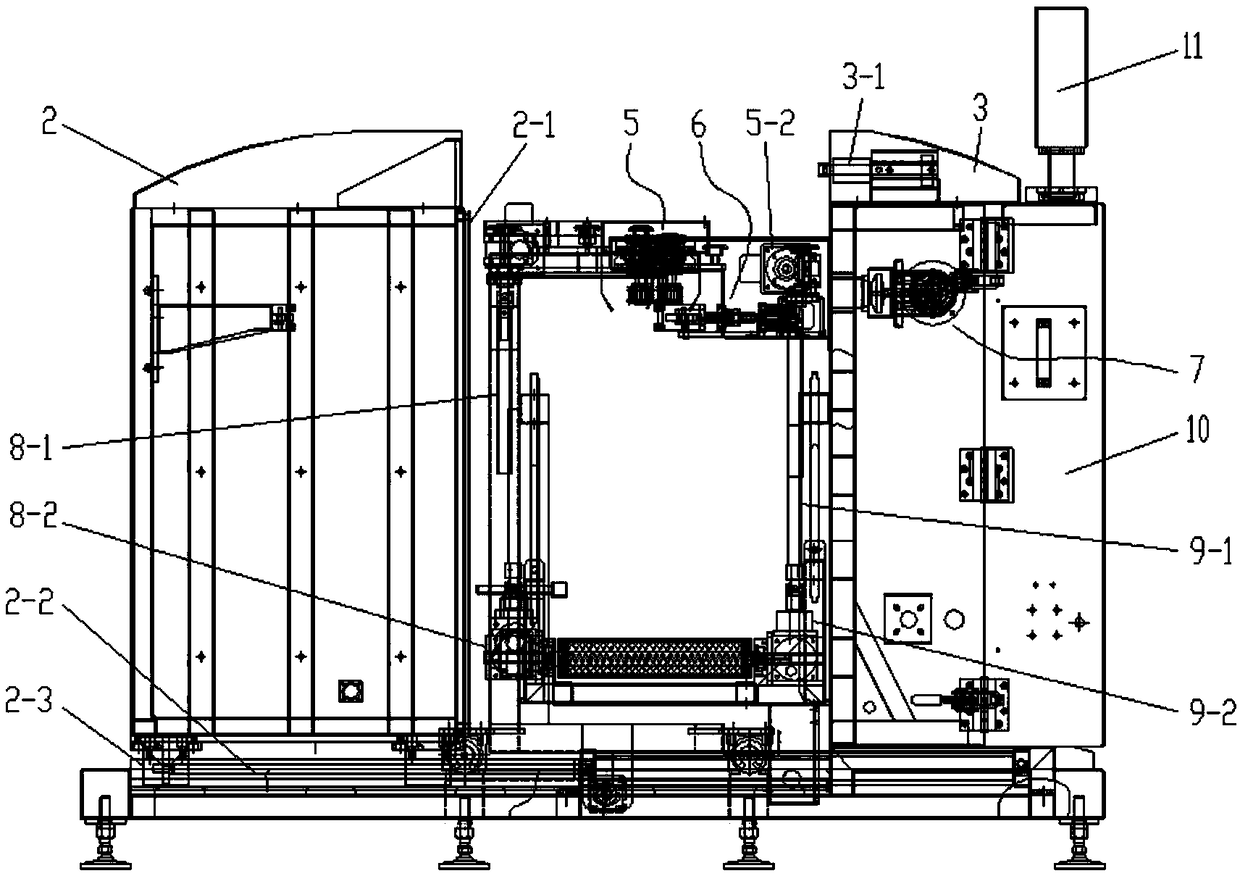

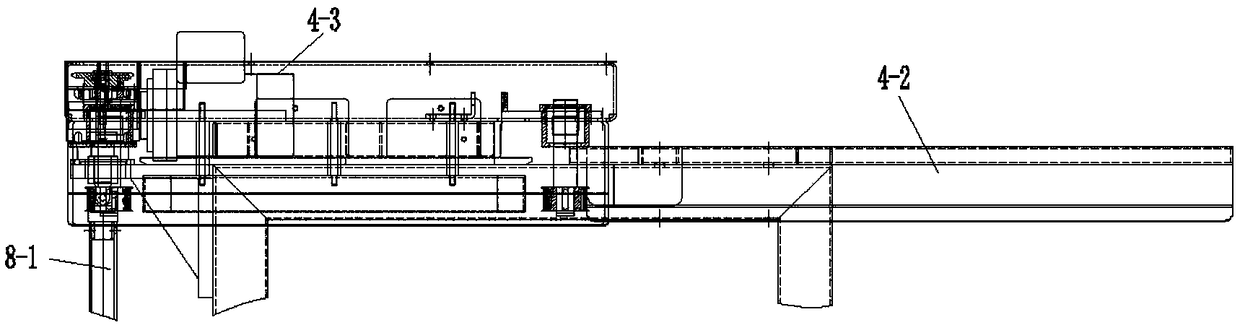

[0035] The invention discloses a vacuum heat sealing machine, such as Figure 1-7As shown, it includes a bracket and a movable box 2 directly or indirectly installed on the bracket, a fixed box 3, a material bag pressing mechanism 4, a material bag guiding mechanism 5, a material bag sealing mechanism 6, a vacuum device 7 and transport line.. The fixed box and the movable box are arranged one behind the other, and the movable box is slidingly connected with the bracket back and forth. When the movable box is closed with the fixed box forward, the movable box A closed heat sealing operation space is enclosed with the rear side wall of the fixed box. The material bag pressing mechanism is located on the right side of the heat sealing operation space, and the material bag guiding mechanism is located at the upper part of the heat sealing operation space. The material bag opening press-fitting introduction channel 4-1 of the material bag pressing mechanism and the material bag o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com