Standing device and L-shaped strip superimposing device

A technology of stacking device and strip, which is applied in transportation and packaging, stacking of objects, etc., can solve the problems of inability to meet high-speed operation, low stacking efficiency, and complex mechanism structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

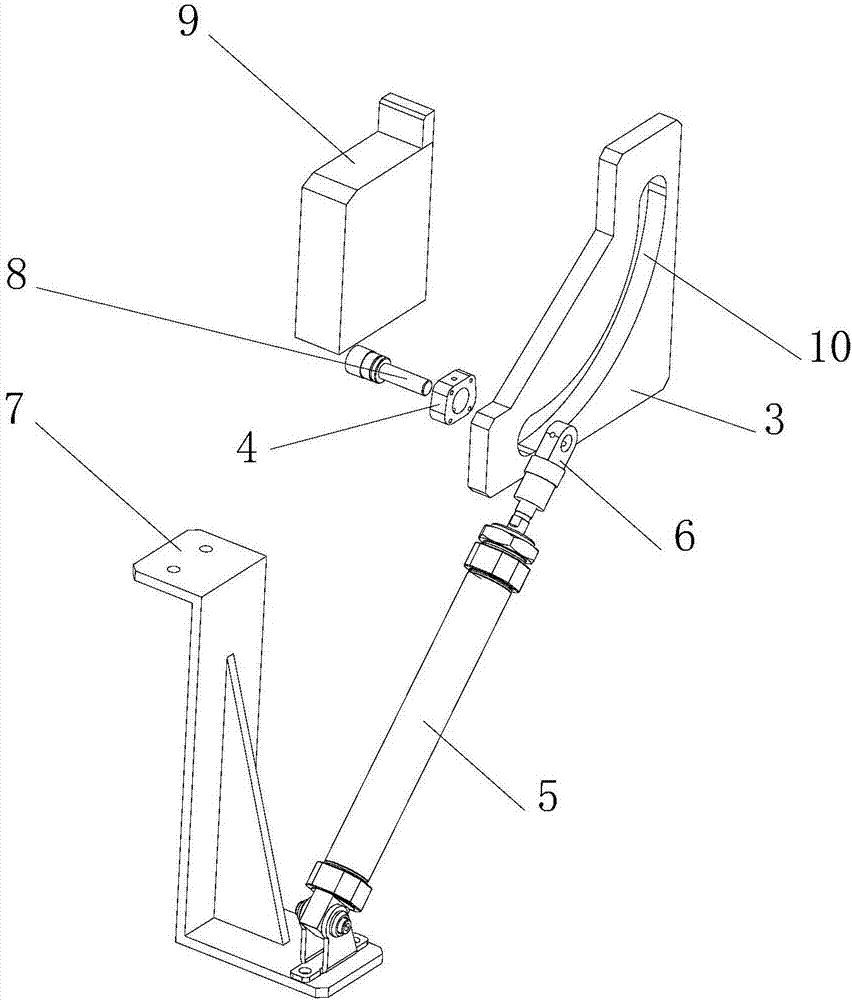

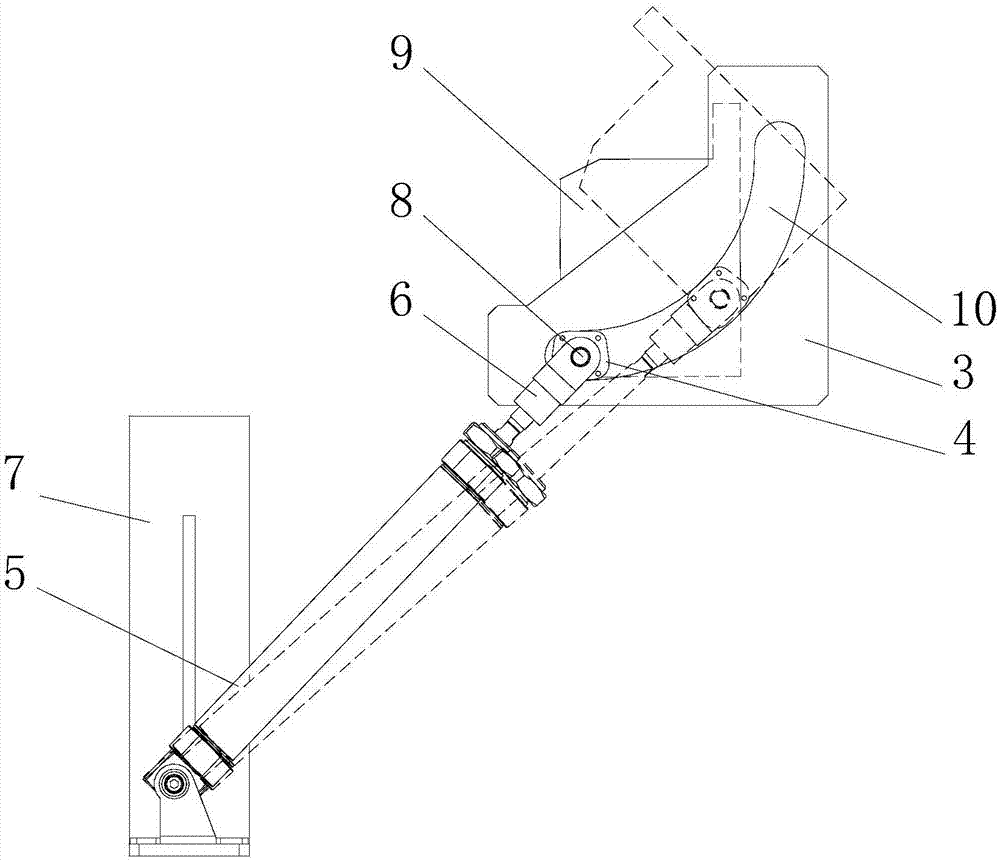

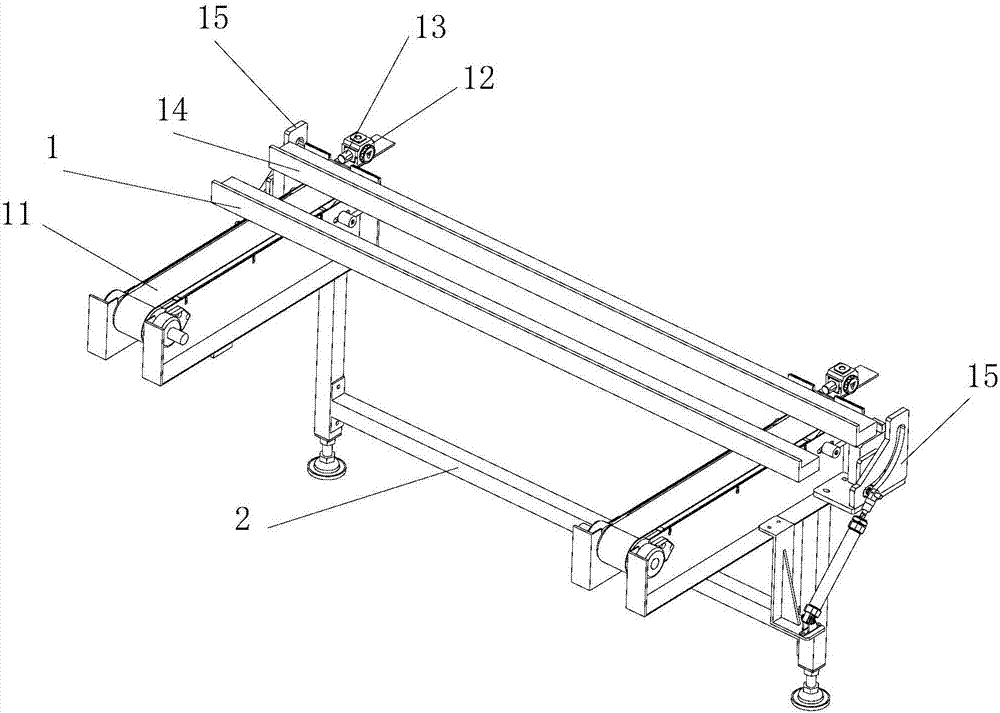

[0047] like Figure 1-5 As shown, a lifting device 15 includes: a guide plate 3, a slider 4, a push block 13, a cylinder 5, a joint 6, a fixed plate 7, a transmission rod 8, and a ┙-shaped plate 9;

[0048] The fixed portion of the push block cylinder 5 is rotatably connected with the fixed plate 7;

[0049] The joint 6 is fixedly connected with the movable rod of the push block cylinder 5;

[0050] The joint 6 is fixedly connected with the transmission rod 8;

[0051] The guide plate 3 is provided with an annular hole 10;

[0052] The slider 4 is sleeved on the transmission rod 8, and the transmission rod 8 rotates along the axis in the slider 4;

[0053] The slider 4 is housed in the annular hole 10, the upper and lower surfaces of the slider 4 are arc-shaped, the diameter of the upper and lower surfaces of the slider 4 is equal to the diameter of the inner and outer edges of the annular hole 10, and the slider 4 is in the shape of a circle. Slide in the annular hole 10;...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap